| [1] Neal RA, McClugage SG, Link MC, et al. Laminin nanofiber meshes that mimic morpholo-gical properties and bioactivity of basement membranes. Tissue Eng. 2009;15(1):11-21. [2] 赵敏丽,隋刚,杨小平,等.电纺丝PLLA/HA复合纤维支架的制备及体外降解性能研究[J].中国生物医学工程学报, 2006,25(4):476-480.[3] Wang S, Zhang Y, Wang H, et al. Fabrication and properties of the electrospun polylactide/silk fibroin-gelatin composite tubular scaffold. Biomacromolecules.2009;10(8):2240-2244.[4] Herrick S, Blanc-Brude O, Gray A, et al. Fibrinogen Int J Biochem Cell Biol. 1999;31(7):741-746. [5] Ayres CE, Jha BS, Sell SA, et al. Nanotechnology in the design of soft tissue scaffolds: innovations in structure and function. Wiley Interdiscip Rev Nanomed Nanobiotechnol. 2010;2(1):20-34. [6] Spotnitz WD. Commercial fibrin sealants in surgical care. Am J Surg. 2001;182(2):8S-14S. [7] Balasubramanian P, Prabhakaran MP, Kai D. Human cardiomyocyte interaction with electros-pun fibrinogen/gelatin nanofibers for myocardial regeneration. J Biomater Sci Polym Ed. 2013;24(14):1660-1675. [8] Linnes MP, Ratner BD, Giachelli CM. A fibrinogen-based precision microporous scaffold for tissue engineering. Biomaterials. 2007;28(35): 5298-5306. [9] McManus MC, Boland ED, Simpson DG, et al. Electrospun fibrinogen: feasibility as a tissue engineering scaffold in a rat cell culture model. J Biomed Mater Res A. 2007;81(2):299-309. [10] McManus M, Boland E, Sell S, et al. Electrospun nanofibre fibrinogen for urinary tract tissue reconstruction. Biomed Mater. 2007;2(4):257-262. [11] Gugutkov D, Gustavsson J, Cantini M, et al. Electrospun fibrinogen-PLA nanofibres for vas-cular tissue engineering. J Tissue Eng Regen Med. 2017;11(10):2774-2784. [12] Sell SA, McClure MJ, Garg K, et al. Electrospinning of collagen/ biopolymers for regenerative medicine and cardiovascular tissue engineering. Adv Drug Deliv Rev. 2009;61(12):1007-1019. [13] Ye Q, Zünd G, Benedikt P, et al. Fibrin gel as a three dimensional matrix in cardiovascular tissue engineering. Eur J Cardiothorac Surg. 2000;17(5):587-591. [14] Sell SA, McClure MJ, Garg K, et al. Electrospinning of collagen/ biopolymers for regenerative medicine and cardiovascular tissue engineering. Adv Drug Deliv Rev. 2009;61(12):1007-1019. [15] Kondo M, Niwa T, Okamoto H, et al. Particle characterization of poorly water-soluble drugs using a spray freeze dryingtechnique. Chem Pharm Bull (Tokyo). 2009;57(7):657-662. [16] Carlisle CR, Coulais C, Namboothiry M, et al. The mechanical properties of individual, electrospun fibrinogen fibers. Biomaterials. 2009;30(6):1205-1213. [17] McManus MC, Boland ED, Simpson DG, et al. Electrospun fibrinogen: feasibility as a tissue engineering scaffold in a rat cell culture model. J Biomed Mater Res A. 2007;81(2):299-309. [18] Zhang Y, Ye C, Wang G, et al. Kidney-targeted transplantation of mesenchymal stem cells by ultrasound-targeted microbubble destruction promotes kidney repair in diabetic nephropathy rats. Biomed Res Int. 2013;2013:526367. [19] 张丽文,罗瑞明,李亚蕾,等.食品真空冷冻联合干燥技术研究进展[J].中国调味品,2017,42(3):152-156. [20] 史宏灿,徐志飞,秦雄,等.生物材料人工气管的设计与动物实验研究[J].第二军医大学学报,2002,6(10):1142-1145. |

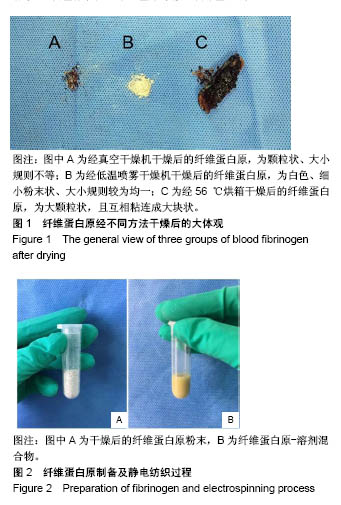

.jpg)

.jpg)