Chinese Journal of Tissue Engineering Research ›› 2025, Vol. 29 ›› Issue (在线): 1-9.

Investigating the effect of the mechanical wear on abutment screw in Morse taper connection implant implant system by using finite element analysis

Xu Hao1,2, Ding Lu2, Li Xiao1,2

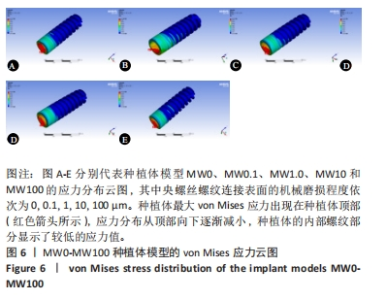

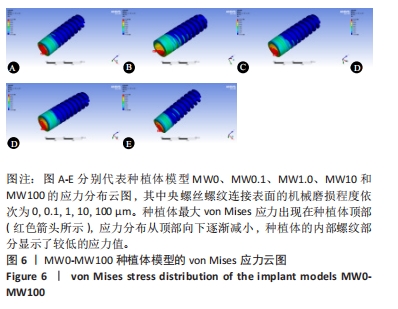

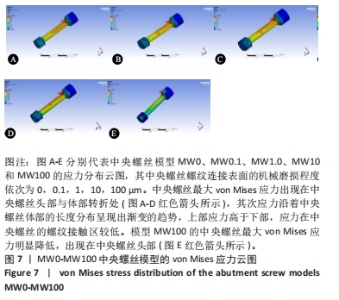

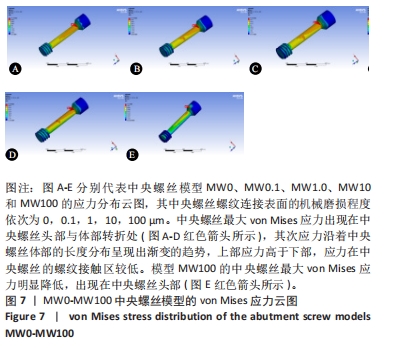

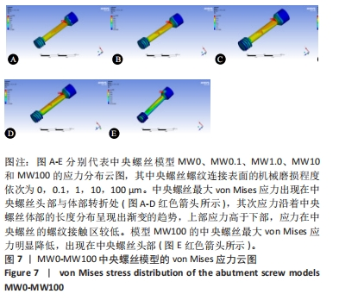

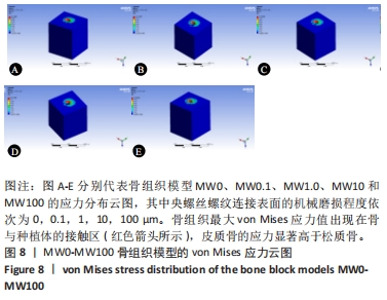

- 1School of Stomatology, Southern Medical University,Guangzhou 510515,Guangdong Province, China; 2Department of Stomatology,General Hospital of Southern Theater Command,Guangzhou 510010,Guangdong Province, China