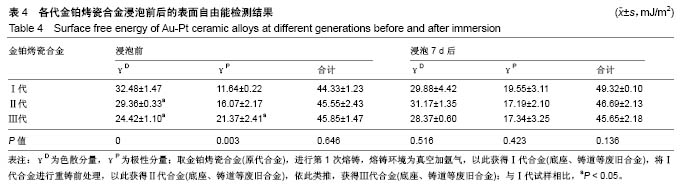

| [1] Vaillantcorroy AS,Corne P,De MP,et al.Influence of recasting on the quality of dental alloys: A systematic review.J Prosthet Dent. 2015; 114(2):205-211.[2] 王颖卉,邱芬芳,吴维青,等.真空充氩反复熔铸对烤瓷合金化学成分的影响[J].华西口腔医学杂志,2018,36(2):174-177.[3] 程辉,杨松,李秀容,等.反复熔铸对金铂烤瓷合金力学性能影响的研究[J].华西口腔医学杂志,2013,31(4): 412-414.[4] ISO10271:2011 Dentistry-Corrosion test methods for metallic materials [S]. BS Institution, 2011.[5] Lin H,Zhang H,Li X,et al.Treatment of multiple ceramic alloys before recasting.J Prosthet Dent.2013;110(1):29-40.[6] 杨智,顾浩,傅远飞.可摘局部义齿支架用钴铬合金的腐蚀相关因素[J].口腔颌面修复学杂志,2017,18(6):359-362.[7] 刘韫嘉,佘文珺.有关牙科合金腐蚀的研究现状[J].口腔材料器械杂志, 2017,26(4):210-213.[8] Wataha JC.Biocompatibility of dental casting alloys: a review. J Prosthet Dent.2000;83(2):223-234.[9] Johnson A,Shiraishi T,Al-Salehi SK.Ion release from experimental Au-Pt-based metal-ceramic alloys.Dent Mater. 2010;26(7):682-687.[10] Bauci? M,Celebi? A,Stipeti? J,et al.In vitro release of metal ions from a gold-platinum alloy in saliva-simulated conditions. Coll Antropol. 2003; 27 Suppl 2:91-98.[11] Elshahawy W,Watanabe I,Koike M.Elemental ion release from four different fixed prosthodontic materials.Dent Mater. 2009;25(8):976-981.[12] 曾强,李玉玲.五种烤瓷合金在人工唾液中的离子析出研究[J].现代口腔医学杂志,2008,22(6):621-623.[13] Peraire M,Martinez-Gomis J,Anglada JM,et al.Effects of re- casting on the chemical composition, microstructure, microhard- ness, and ion release of 3 dental casting alloys and titanium.Int J Prosthodont. 2007; 20(3):286-288.[14] Zhang S,Qiu J,Ren Y,et al. Reciprocal interaction between dental alloy biocorrosion and Streptococcus mutans virulent gene expression. J Mater Sci Mater Med.2016;27(4):78.[15] Bollen CM,Lambrechts P,Quirynen M.Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: a review of the literature.Dent Mater. 1997;13(4):258-269.[16] Knorr SD,Combe EC,Wolff LF,et al.The surface free energy of dental gold-based materials.Dent Mater.2005;21(3):272-277.[17] Quirynen M,Marechal M,Busscher HJ,et al.The influence of surface free energy and surface roughness on early plaque formation. An in vivo study in man.J Clin Periodontol. 1990;17(3):138-144.[18] Nakamura M,Hori N,Ando H,et al.Surface free energy predominates in cell adhesion to hydroxyapatite through wettability. Mater Sci Eng C. 2016;62:283-292. |