Chinese Journal of Tissue Engineering Research ›› 2017, Vol. 21 ›› Issue (6): 821-828.doi: 10.3969/j.issn.2095-4344.2017.06.001

Preparation and characterization of an injectable bioactive calcium phosphate material for bone repair

- 1Zhujiang Hospital of Southern Medical University, Guangzhou 510280, Guangdong Province, China; 2Research Institute of Tsinghua University in Shenzhen, Shenzhen 518057, Guangdong Province, China

-

Received:2017-01-10Online:2017-02-28Published:2017-03-16 -

Contact:Li Song-jian, M.D., Chief physician, Zhujiang Hospital of Southern Medical University, Guangzhou 510280, Guangdong Province, China -

About author:Liu Jian-xiu, Master, Physician, Zhujiang Hospital of Southern Medical University, Guangzhou 510280, Guangdong Province, China -

Supported by:the National Natural Science Foundation of China, No. 51303094

CLC Number:

Cite this article

Liu Jian-xiu, Shen Ying, Chu Bin, Zeng Fei, Huang Shi-jia, Li Song-jian. Preparation and characterization of an injectable bioactive calcium phosphate material for bone repair[J]. Chinese Journal of Tissue Engineering Research, 2017, 21(6): 821-828.

share this article

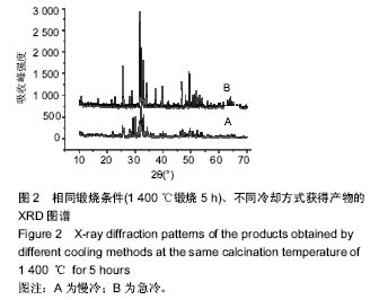

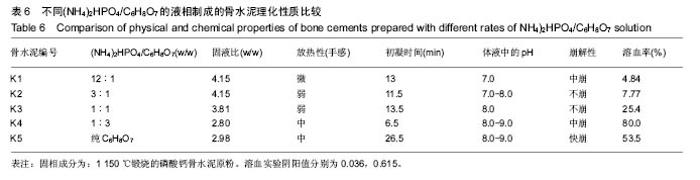

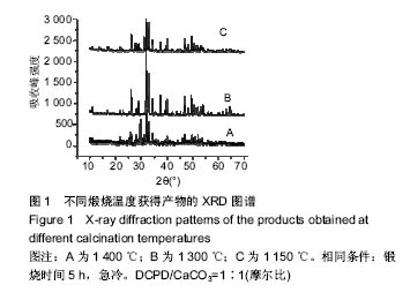

2.1 磷酸四钙基磷酸钙骨水泥原粉制备的影响因素 磷酸钙骨水泥主要通过骨水泥固相和水溶液发生水化反应而自然凝固[10],因此,骨水泥原粉的合成是磷酸钙骨水泥制备的关键。骨水泥原粉通常采用CaHPO4与CaCO3在高温下进行固相反应获得,控制反应条件(温度、原料配比等)可得到不同的产物,为磷酸四钙、α-磷酸三钙和羟基磷灰石,以及其中两者或三者的混合物。骨水泥原粉的必要组分是磷酸四钙,依靠它的水溶性才使水泥具有黏结性,同时它还直接影响到水泥的强度、酸碱性和生物相容性等一系列性质。这里粗略讨论了反应温度、冷却方式,原料的理化性质对磷酸四钙基磷酸钙骨水泥原粉制备的影响。 2.1.1 反应温度的影响 将图1和标准XRD图谱数据(表2)对比,可以看出,1 150 ℃煅烧得到的产物为羟基磷灰石+ α-Ca3(PO4)2(2θ=27.905,29.072,34.211,34.492)+β-Ca3 (PO4)2(2θ=33.049,37.489,46.816),其中α、β-磷酸钙含量较少,羟基磷灰石的含量较多;在1 300 ℃锻烧得到的产物主要为纯度和结晶度均较高的羟基磷灰石;而在 1 400 ℃锻烧得到的产物为磷酸四钙,还含有少量的羟基磷灰石。在所有的谱图中均不含有CaO,说明固相反应比较充分,反应物无过量。 根据文献,以CaHPO4•2H2O和CaCO3为原料通过固相反应制备磷酸四钙的反应,存在如下物质转变过程[8]: 由上述反应式可以解释不同温度所获得的产物的差异。当反应在1 150 ℃下进行时,Ca2P2O7与CaO反应生成β-磷酸钙与羟基磷灰石,由于未达到α-磷酸钙的转化温度,故产物中同时含有α-磷酸钙与β-磷酸钙,而反应温度均未达到羟基磷灰石分解或磷酸钙与CaO发生固相反应生成磷酸四钙的温度,故产物中未出现磷酸四钙;在1 300 ℃下,反应物Ca2P2O7与CaO反应得到纯度很高的羟基磷灰石,但由于反应温度未达到羟基磷灰石分解温度(1 350 ℃),故产物中不含有磷酸四钙;在1 400 ℃时,反应温度超过羟基磷灰石分解温度,羟基磷灰石分解为磷酸四钙,故反应产物中主要含磷酸四钙。由于羟基磷灰石高温下的结晶度比磷酸四钙高,尽管图谱中羟基磷灰石特征峰衍射强度较高,但实际含量并不高。由此可见,只有当反应温度大于1 400 ℃才有可能出现大量的磷酸四钙,因此,从磷酸四钙含量和能耗两方面考虑,1 400 ℃是制备磷酸四钙基骨水泥原粉的最佳温度。"

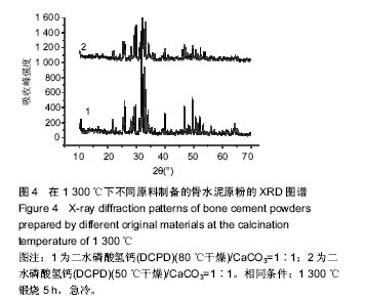

2.1.3 原料理化性质的影响 粉料的研磨和过筛是骨水泥研制中极其重要的一环,因为粉料颗粒大小直接影响到骨水泥的性能,实验首先采用球磨机研磨,但发现在研磨的过程中二水磷酸氢钙易析出结晶水,导致粉料黏附在球磨罐壁以及球磨球上,而且球磨后粉料的颗粒依然很大,以致在过筛过程中造成了困难,所以放弃使用球磨机而改用手磨。 将二水磷酸氢钙和无水磷酸氢钙分别与CaCO3高温反应(图3),发现1 300 ℃时以无水磷酸氢钙为原料,主要产物为磷酸钙+羟基磷灰石,而以二水磷酸氢钙为原料则得到几乎100%的羟基磷灰石。由于磷酸四钙主要由羟基磷灰石分解而来,因此羟基磷灰石纯度越高,磷酸四钙含量越高;由此可以看出,以二水磷酸氢钙为原料比无水磷酸氢钙要好,有可能获得更高含量的磷酸四钙。 实验还比较了以不同干燥温度的二水磷酸氢钙为原料对反应产物的影响(图4)。由图可见,采用80 ℃下干燥的二水磷酸氢钙使产物中羟基磷灰石含量增多,磷酸四钙含量减少,这可能是由于二水磷酸氢钙失去了部分结晶水,使中间产物纯度降低所致;而采用50 ℃下干燥的二水磷酸氢钙,产物中磷酸四钙含量相当高,因此二水磷酸氢钙干燥的适宜温度是低于50 ℃。"

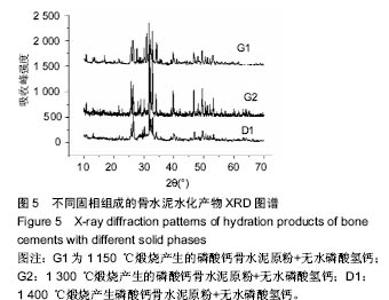

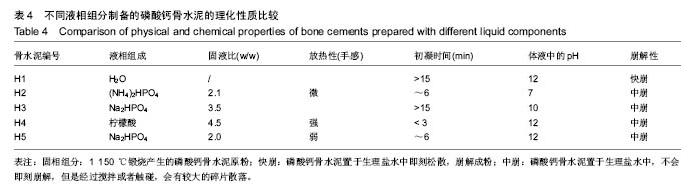

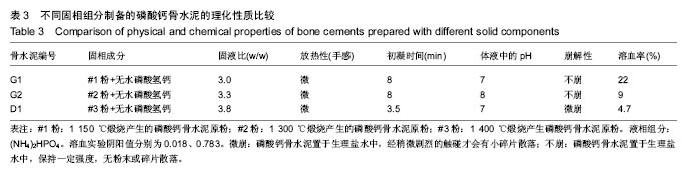

2.2 骨水泥制备的影响因素及条件优化 2.2.1 固相和液相组分的选择 经X射线衍射测定表明,在固化前的固体相由Ca4(PO4)2O和CaH(PO4)等组成。经过液相调和后,其组分基本转化成羟基磷灰石的结构,而羟基磷灰石则是人体骨组织的主要成分,它占人体骨组织的70%左右,因此,从化学结构上决定了磷灰石骨水泥的人体骨相似性,也决定了磷灰石骨水泥与人体骨组织具有很好的生物相容性。 磷酸钙骨水泥形成的原因是由于不同磷酸钙盐溶解度不同所致。实验比较了采用不同温度煅烧得到的磷酸钙骨水泥原粉制备出的磷酸钙骨水泥的各种理化性质(表3),发现#3粉制备的D1号磷酸钙骨水泥初凝时间最短,体液中pH值变化最小,崩解性不高,溶血率最低(低于5%),其原因与磷酸四钙含量增加,水化产物中纳米羟基磷灰石含量相应增多以及羟基磷灰石晶体结构与人体骨近似(图5)有关。 "

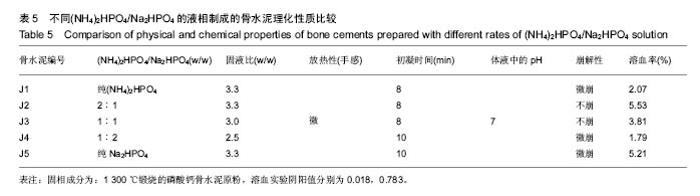

2.2.2 NH4-Na液相体系制备骨水泥条件优化 考虑到采用纯(NH4)2HPO4为液相组分,水化过程中会释放氨气,使体液在较长时间内偏碱性,因此采用Na2HPO4调节水化产物的酸碱性。另外,由于骨水泥的抗压强度与羟基磷灰石的转化生成密切相关, 而Na+盐比NH4+盐更易水解,Na+的替代行为会引起晶格的畸变,促进羟基磷灰石的转化和生 成,因此采用Na+盐作为添加剂制成骨水泥可提高最大抗压强度。由表5看出,此系列各项理化指标均无太大差异。Na+盐的加入使初凝时间增加。溶血率值基本在正常范围内。当铵、钠盐共存时,在(NH4)2HPO4/Na2HPO4为1︰2时,溶血率值相对最低。可以看出,这种配比(J4)得出的磷酸钙骨水泥血液相容性最好。"

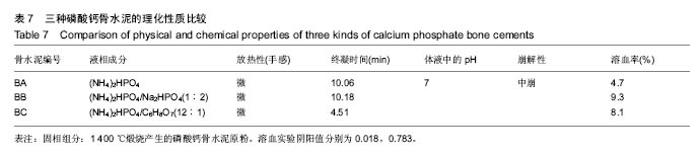

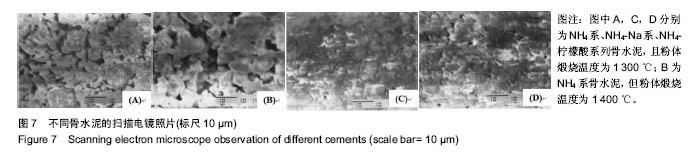

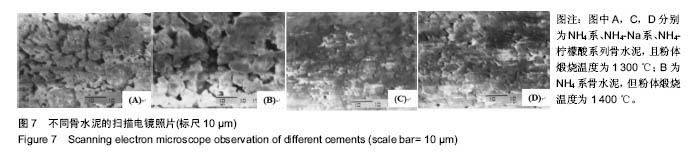

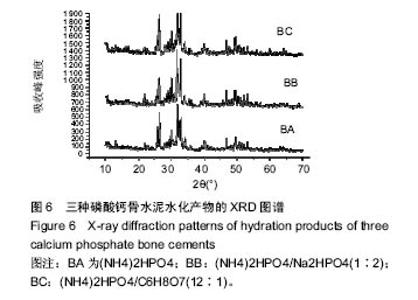

从图6看出,每种水泥均有宽化的羟基磷灰石特征衍射峰,意味着水泥体相是由部分纳米羟基磷灰石组成的,但还存在相当程度的其他磷酸钙盐大晶粒,因此导致水泥强度下降。 从图7的电镜照片中也可看出,没有添加Na或柠檬酸的体系(图7A,B)水泥体相中存在较大缝隙,而添加了Na或柠檬酸的体系(图7C,D)水泥颗粒间结合紧密,无大孔洞(> 5 μm)存在,这与水泥的崩解情况和实际强度情况相符;而采用1 300 ℃煅烧产生的磷酸钙骨水泥原粉制备的水泥G2,J3和K1,其孔洞尺寸和孔隙率均小于1 400 ℃煅烧产生的磷酸钙骨水泥原粉制备的水泥D1,主要原因可能也与大颗粒的磷酸钙盐的存在有关。 由表7还可以看出,3种水泥的溶血率也都比较接近,其中纯NH4体系的水泥溶血率达到5%以下。由于溶血率与固相组分和液相组分的性质密切相关,并且实验值本身误差也很大,还需要做细胞实验以准确判断水泥的生物相容性。"

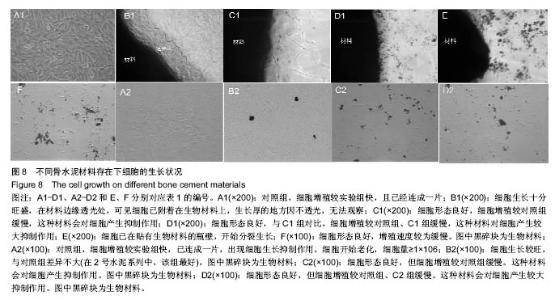

2.3.2 三种磷酸钙骨水泥细胞相容性与细胞毒性比较 由图8可以看出,在液相选择上,NH4/Na比为1︰2的NH4-Na体系的磷酸钙骨水泥细胞相容性最好(图8B1,B2,C1,C2,D1和D2)。将组成不同的磷酸钙骨水泥原粉制成的骨水泥编为1号系列和2号系列,并进行对比,可以得出2号系列比1号系列骨水泥生物相容性更好,更适合做人工骨修复材料(图8B1,C1,D1,B2,C2,D2)。对于E和B1而言,两个样品的磷酸钙骨水泥原粉煅烧温度不同,但主要成分为羟基磷灰石,B1中含少量磷酸三钙。在细胞毒性测试中,E出现崩解,这可能与水泥中仅含大颗粒羟基磷灰石有关。常温常压下E体相中仍含有少量水分,液相组分可以缓慢水解以维持其强度,但高压下水分丧失,导致水泥完全崩解。另外将C2和F进行对比发现,在其他制备条件相同的情况下,原粉经过过筛比没经过过筛的细胞相容性好(图8C2,F)。"

| [1]王梓壬,陈明晃,林建华,等. 羟基磷灰石骨水泥人工骨及其性能研究[J].福建医药杂志,2003,25(1):120-121,119.[2]陈晓明,李世普,罗泽波,等. α-TCP骨水泥水化产物的生物相容性研究[J]. 中国生物医学工程学报, 1996,15(3):233-238.[3]马俊华,孙吉林,王智勇,等. 多孔羟基磷灰石修复关节骨及软骨缺损的实验研究[J].河北医学院学报, 1995,16(5): 257-260,321.[4]黎兵,李玉宝,陈继镛,等. 磷酸钙生物活性骨水泥的制备及其性能的研究[J].四川大学学报:自然科学版, 1998,35(2): 191-194.[5]王士斌,翁连进,郑昌琼,等.骨形态发生蛋白/多孔β-磷酸三钙陶瓷复合人工骨[J].四川大学学报:工程科学版,1999,3(5):5-8.[6]孙明林,胡蕴玉,雷伟,等. 磷酸钙骨水泥/BMP复合人工骨的理化性能及缓释作用[J].第三军医大学学报, 2001,23(7): 800-802.[7]杨莽,张彩霞,陈德敏. 磷酸钙骨水泥的生物学研究进展[J].国外医学:生物医学工程分册,2001,24(5):222-225.[8]阮孜炜,李东旭. 磷酸四钙合成机理及其稳定性研究[J].材料科学与工程学报, 2004,22(2): 193-196.[9]周馨,郑昌琼,王方瑚,等. 一种新型磷酸钙骨水泥的制备、基本性能的研究及生物安全性评价[J].生物医学工程学杂志, 1999, 16(z1): 56-59.[10]邵慧芳,刘昌胜,黄粤,等. 羟基磷灰石晶种的形貌控制及其对磷酸钙骨水泥的原位增强研究[J].无机材料学报, 2001,16(5): 933-939. |

| [1] | Yao Xiaoling, Peng Jiancheng, Xu Yuerong, Yang Zhidong, Zhang Shuncong. Variable-angle zero-notch anterior interbody fusion system in the treatment of cervical spondylotic myelopathy: 30-month follow-up [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(9): 1377-1382. |

| [2] | An Weizheng, He Xiao, Ren Shuai, Liu Jianyu. Potential of muscle-derived stem cells in peripheral nerve regeneration [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(7): 1130-1136. |

| [3] | Zhang Jinglin, Leng Min, Zhu Boheng, Wang Hong. Mechanism and application of stem cell-derived exosomes in promoting diabetic wound healing [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(7): 1113-1118. |

| [4] | He Yunying, Li Lingjie, Zhang Shuqi, Li Yuzhou, Yang Sheng, Ji Ping. Method of constructing cell spheroids based on agarose and polyacrylic molds [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 553-559. |

| [5] | He Guanyu, Xu Baoshan, Du Lilong, Zhang Tongxing, Huo Zhenxin, Shen Li. Biomimetic orientated microchannel annulus fibrosus scaffold constructed by silk fibroin [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 560-566. |

| [6] | Chen Xiaoxu, Luo Yaxin, Bi Haoran, Yang Kun. Preparation and application of acellular scaffold in tissue engineering and regenerative medicine [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 591-596. |

| [7] | Kang Kunlong, Wang Xintao. Research hotspot of biological scaffold materials promoting osteogenic differentiation of bone marrow mesenchymal stem cells [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 597-603. |

| [8] | Shen Jiahua, Fu Yong. Application of graphene-based nanomaterials in stem cells [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 604-609. |

| [9] | Zhang Tong, Cai Jinchi, Yuan Zhifa, Zhao Haiyan, Han Xingwen, Wang Wenji. Hyaluronic acid-based composite hydrogel in cartilage injury caused by osteoarthritis: application and mechanism [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 617-625. |

| [10] | Li Hui, Chen Lianglong. Application and characteristics of bone graft materials in the treatment of spinal tuberculosis [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 626-630. |

| [11] | Gao Cangjian, Yang Zhen, Liu Shuyun, Li Hao, Fu Liwei, Zhao Tianyuan, Chen Wei, Liao Zhiyao, Li Pinxue, Sui Xiang, Guo Quanyi. Electrospinning for rotator cuff repair [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 637-642. |

| [12] | Guan Jian, Jia Yanfei, Zhang Baoxin , Zhao Guozhong. Application of 4D bioprinting in tissue engineering [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(3): 446-455. |

| [13] | Liu Jiali, Suo Hairui, Yang Han, Wang Ling, Xu Mingen. Influence of lay-down angles on mechanical properties of three-dimensional printed polycaprolactone scaffolds [J]. Chinese Journal of Tissue Engineering Research, 2022, 10(16): 2612-2617. |

| [14] | Huang Bo, Chen Mingxue, Peng Liqing, Luo Xujiang, Li Huo, Wang Hao, Tian Qinyu, Lu Xiaobo, Liu Shuyun, Guo Quanyi . Fabrication and biocompatibility of injectable gelatin-methacryloyl/cartilage-derived matrix particles composite hydrogel scaffold [J]. Chinese Journal of Tissue Engineering Research, 2022, 10(16): 2600-2606. |

| [15] | Fang Xiaoyang, Tang Tian, Wang Nan, Qian Yuzhang, Xie Lin. Repair and regenerative therapies of the annulus fibrosus [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(10): 1582-1587. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||