Chinese Journal of Tissue Engineering Research

Previous Articles Next Articles

Production and functional testing of polyurethane valve of the pediatric Luo-Ye pump

Wu Yue-heng1, 2, Huang Huan-lei2, Fan Rui-xin2, Qi Zhou-cuo1, Yao Li-ming1, Wu Chang-li2, Lu Ping-lan2, Cheng An-heng1, Xiao Xue-jun2

- 1Medical Research Center, 2Department of Cardiovascular Surgery, Guangdong Provincial Cardiovascular Institute, Guangdong General Hospital, Guangdong Academy of Medical Science, Guangzhou 510100, Guangdong Province, China

-

Received:2012-11-10Revised:2013-01-24Online:2013-07-30Published:2013-07-30 -

Contact:Xiao Xue-jun, M.D., Chief physician, Researcher, Department of Cardiovascular Surgery, Guangdong General Hospital, Guangdong Provincial Cardiovascular Institute, Guangdong Academy of Medical Science, Guangzhou 510100, Guangdong Province, China xiaoxuejun@tom.com -

About author:Wu Yue-heng★, Master, Assistant researcher, Medical Research Center, Guangdong Provincial Cardiovascular Institute, Guangdong General Hospital, Guangdong Academy of Medical Science, Guangzhou 510100, Guangdong Province, China edgar_wu@yahoo.com.cn -

Supported by:National Natural Science Foundation of China, No. 30901468*; Combining Production and Research Project of Ministry of Education of Guangdong Province, No. 2008B090500210*

CLC Number:

Cite this article

Wu Yue-heng, Huang Huan-lei, Fan Rui-xin, Qi Zhou-cuo, Yao Li-ming, Wu Chang-li, Lu Ping-lan, Cheng An-heng, Xiao Xue-jun. Production and functional testing of polyurethane valve of the pediatric Luo-Ye pump[J]. Chinese Journal of Tissue Engineering Research, doi: 10.3969/j.issn.2095-4344.2013.31.005.

share this article

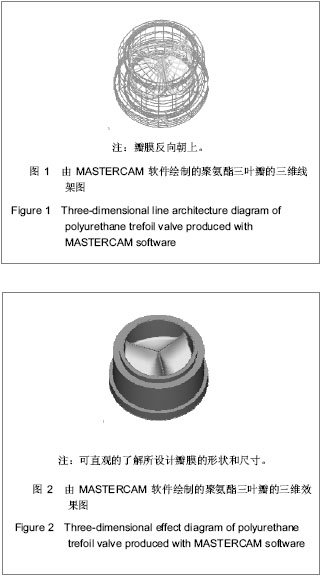

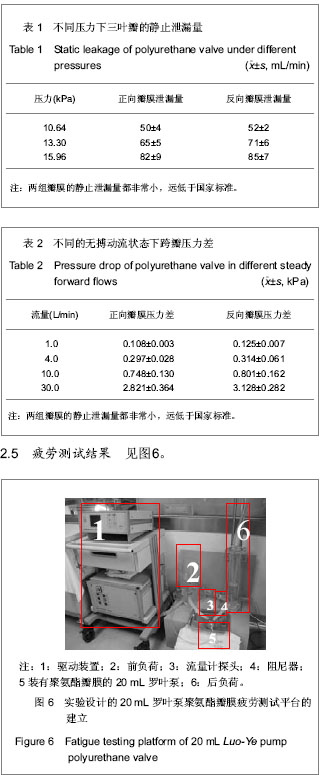

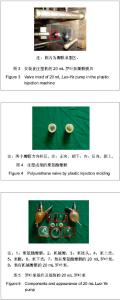

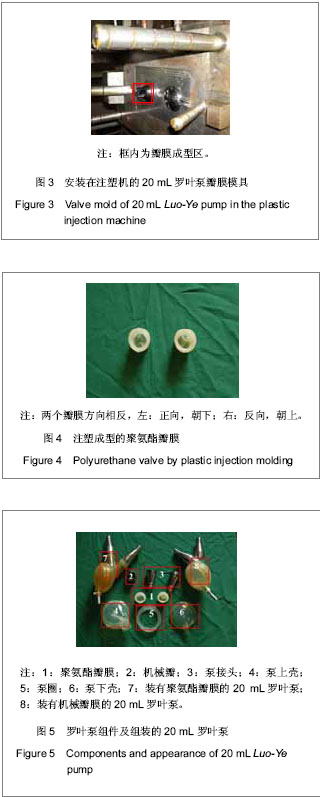

2.2 20 mL罗叶泵聚氨酯瓣膜的制作 图3是安装在注塑机上的瓣膜模具。图4是注塑成功的聚氨酯瓣膜。图5是聚氨酯瓣膜、罗叶泵配件和组装成功的20 mL罗叶泵。由图可知,实验成功的制作了20 mL罗叶泵。在制作过程中,特别要注意聚氨酯瓣膜瓣叶的注塑,因为瓣膜瓣叶比较薄,故其注塑的条件需仔细调节。瓣膜注塑的成功率较低,约为15%。 2.3 静止泄露测试结果 表1是两种三叶瓣的静止泄漏量,其测试过程参考GB 12279-2005(ISO5840-1990)。结果显示,两组瓣膜的静止泄漏量都非常小,远低于国家标准。静止泄漏量反映了瓣膜在静止状态下的闭合情况,结果显示瓣膜闭合非常好,其返流主要发生在三片瓣叶汇集的地方,即瓣膜中心处。"

| [1] Birks EJ, George RS, Hedger M, et al. Reversal of severe heart failure with a continuous-flow left ventricular assist device and pharmacological therapy: a prospective study. Circulation. 2011;123(4):381-390. [2] Williams ML, Trivedi JR, McCants KC, et al. Heart transplant vs left ventricular assist device in heart transplant-eligible patients. Ann Thorac Surg. 2011;91(5):1330-1333; discussion 1333-1334.[3] Mehra MR, Domanski MJ.Should left ventricular assist device should be standard of care for patients with refractory heart failure who are not transplantation candidates?: left ventricular assist devices should be considered standard of care for patients with refractory heart failure who are not transplantation candidates. Circulation.2012;126(25):3081-3087.[4] Kroekel PA, George L, Eltoukhy N. How to Manage the Patient in the Emergency Department with a Left Ventricular Assist Device. J Emerg Nurs. 2012 May 15.[5] Weiss WJ, Carney EL, Clark JB, et al. Chronic in vivo testing of the Penn State infant ventricular assist device. ASAIO J. 2012;58(1):65-72.[6] Stege D, Kiski D, Tjan T, et al. 1-year left ventricular assist device (LVAD) experience as bridge to heart transplantation in an infant with Bland-White-Garland syndrome. Thorac Cardiovasc Surg. 2010;58 Suppl 2:S167-169. [7] Dunnington GH Jr, Sleasman J, Alkhaldi A, et al. Successful bridge to transplant using the Berlin Heart left ventricular assist device in a 3-month-old infant. Ann Thorac Surg. 2006; 81(3):1116-1118. [8] Lawson DS, Lawson AF, Walczak R, et al. North American neonatal extracorporeal membrane oxygenation (ECMO) devices and team roles: 2008 survey results of Extracorporeal Life Support Organization (ELSO) centers. J Extra Corpor Technol. 2008;40(3):166-174. [9] Mathis CA, Powell AE, Holloway RD, et al. Alternative cannulation strategy for pediatric ECMO. J Card Surg. 2011; 26(4):444-445.[10] Anastasiadis K, Chalvatzoulis O, Antonitsis P, et al. Left ventricular decompression during peripheral extracorporeal membrane oxygenation support with the use of the novel iVAC pulsatile paracorporeal assist device. Ann Thorac Surg. 2011;92(6):2257-2259.[11] Jeewa A, Manlhiot C, McCrindle BW, et al. Outcomes with ventricular assist device versus extracorporeal membrane oxygenation as a bridge to pediatric heart transplantation. Artif Organs. 2010;34(12):1087-1091.[12] Zhao M, Wu B, Yang S, et al. Analysis of cardiopulmonary bypass status in China: eight-year development trends. Perfusion. 2013;28(1):21-25.[13] Xiao XJ, Luo ZX, Ye CX, et al. The short-term pulsatile ventricular assist device for postcardiotomy cardiogenic shock: a clinical trial in China. Artif Organs. 2009;33(4): 373-377. [14] Zhang Y, Hu SS, Zhou JY, et al. Design and performance testing of an axial-flow ventricular assist device developed at the Fu Wai Hospital in Beijing. Int J Artif Organs. 2008; 31 (11):983-987.[15] Zi-Bin Y, Yan H, Pin ZA,et al. Current status of research on the left ventricular assist device in Beijing, China. Cardiovasc Dis. 1981;8(3):385-393. [16] Fraser CD Jr, Jaquiss RD, Rosenthal DN, et al. Prospective trial of a pediatric ventricular assist device. N Engl J Med. 2012;367(6):532-541.[17] Papademetriou MD, Tachtsidis I, Banaji M, et al. Regional cerebral oxygenation measured by multichannel near-infrared spectroscopy (optical topography) in an infant supported on venoarterial extracorporeal membrane oxygenation. J Thorac Cardiovasc Surg. 2011;141(5):e31-33. [18] Hollander SA, Reinhartz O, Chin C, et al. Use of the Impella 5.0 as a bridge from ECMO to implantation of the HeartMate II left ventricular assist device in a pediatric patient. Pediatr Transplant. 2012;16(2):205-206.[19] Schönberger M, Deutsch S, Manning KB. The influence of device position on the flow within the Penn State 12 cc pediatric ventricular assist device. ASAIO J. 2012;58(5): 481-493.[20] Johnson CA Jr, Vandenberghe S, Daly AR, et al. Biocompatibility assessment of the first generation PediaFlow pediatric ventricular assist device. Artif Organs. 2011;35(1): 9-21.[21] Ko WJ, Lin CY, Chen RJ, et al. Extracorporeal membrane oxygenation support for adult postcardiotomy cardiogenic shock. Ann Thorac Surg. 2002;73(2):538-545.[22] Wang W, Zhu DM, Ding WX. Development of mechanical circulatory support devices in China. Artif Organs. 2009; 33(11):1009-1014. [23] Zhu DM, Wang W, Chen H, et al. Left ventricular assist device for pediatric postcardiotomy cardiac failure. ASAIO J.2006; 52(5):603-604. [24] 吴岳恒.婴幼儿罗叶泵与柏林Excor泵在动物实验中的初步研究[J].中国病理生理杂志,2010,26(10):1995.[25] 黄焕雷,祁周措,姚丽明,等.20mL小儿罗叶泵的动物存活实验[J]. 北京生物医学工程,2012,31(3):251-257.[26] Chang AC, Hanley FL, Weindling SN, et al. Left heart support with a ventricular assist device in an infant with acute myocarditis. Crit Care Med. 1992;20(5):712-715. [27] Aleksieva G, Hollweck T, Thierfelder N, et al. Use of a special bioreactor for the cultivation of a new flexible polyurethane scaffold for aortic valve tissue engineering. Biomed Eng Online. 2012 Dec 4;11:92.[28] 江燕萍,吴岳恒,成安衡.多孔偏磷酸钙生物材料的体外加速降解实验[J].中国组织工程研究与临床康复,2008,12(19): 3663-3666.[29] Zapanta CM, Dourte LM, Doxtater BJ, et al. Mechanical heart valve performance in a pulsatile pediatric ventricular assist device. ASAIO J. 2007;53(1):87-96. [30] Suh SW, Kim WG, Kim HC, et al. A new polymer valve for mechanical circulatory support systems. Int J Artif Organs. 1996;19(12):712-718. [31] 李海洋,吴广辉,王成德,等.磁悬浮离心血心室辅助装置在体实验及其血液相容性[J].中国组织工程研究,2012,16(43):8061- 8066.[32] 吴广辉,蔺嫦燕,陈琛,等.磁悬浮离心式心室辅助装置的体外溶血测试[J].中国组织工程研究, 2012,16(21):3886-3890.[33] Lee H, Ikeuchi Y, Akagawa E, et al. Effects of leaflet geometry on the flow field in three bileaflet valves when installed in a pneumatic ventricular assist device. J Artif Organs. 2009; 12(2):98-104.[34] 李国荣,朱晓东,彭远仪,等.叶轮泵式全人工心脏的结构设计及流体力学特性[J].生物医学工程与临床,2008,12(3):167-170.[35] 李国荣,朱晓东,彭远仪,等.前导叶对轴流泵式心脏辅助装置流体力学特性的影响及改进意义[J].医疗卫生备,2007,28(8):5-7. |

| [1] | Yang Xin, Jin Zhe, Feng Xu, Lu Bing. The current situation of knowledge and attitudes towards organ, eye tissue, body donation of residents in Shenyang [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 779-784. |

| [2] | Zhao Chuntao, Qing Mingsong, Yu Langbo, Peng Jiachen . Meta-analysis of total knee arthroplasty guided by kinematic alignment and mechanical alignment [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(9): 1435-1442. |

| [3] |

Zhang Cong, Zhao Yan, Du Xiaoyu, Du Xinrui, Pang Tingjuan, Fu Yining, Zhang Hao, Zhang Buzhou, Li Xiaohe, Wang Lidong.

Biomechanical analysis of the lumbar spine and pelvis in adolescent

idiopathic scoliosis with lumbar major curve |

| [4] |

Cen Yanhui, Xia Meng, Jia Wei, Luo Weisheng, Lin Jiang, Chen Songlin, Chen Wei, Liu Peng, Li Mingxing, Li Jingyun, Li Manli, Ai Dingding, Jiang Yunxia.

Baicalein inhibits the biological behavior of hepatocellular

carcinoma stem cells by downregulation of Decoy receptor 3 expression |

| [5] | He Yujie, Wang Haiyan, Li Zhijun, Li Xiaohe, Cai Yongqiang, Dai Lina, Xu Yangyang, Wang Yidan, Xu Xuebin. Digital measurements of the anatomical parameters of pedicle-rib unit screw fixation in thoracic vertebrae of preschoolers [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(6): 869-876. |

| [6] | Yan Shu, Lu Yan, Ouyang Zhaolian. Analysis of programs on tissue engineering funded by the National Natural Science Foundation of China between 2013 and 2018 [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(5): 731-735. |

| [7] | Sun Jian, Fang Chao, Gao Fei, Wei Laifu, Qian Jun. Clinical efficacy and complications of short versus long segments of internal fixation for the treatment of degenerative scoliosis: a meta-analysis [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(3): 438-445. |

| [8] | Gao Yangyang, Che Xianda, Han Pengfei, Liang Bin, Li Pengcui. Accuracy of robot-assisted and fluoroscopy-guided pedicle screw placement: a meta-analysis [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(3): 446-452. |

| [9] | Zhang Jian, Wang Xiaojian, Qin Dean, Zhao Zhongtao, Liang Qingyuan, An Qijun, Song Jiefu. Risk factors for proximal junctional kyphosis after spinal deformity surgery: a meta-analysis [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(3): 460-468. |

| [10] | Xu Yangyang, Zhang Kai, Li Zhijun, Zhang Yunfeng, Su Baoke, Wang Xing, Wang Lidong, Wang Yidan, He Yujie, Li Kun, Wang Haiyan, Li Xiaohe. Morphological analysis of optimal selection of lumbar pedicle screws in adolescents aged 12-15 years [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(21): 3321-3328. |

| [11] | He Xiaoming, Gong Shuidi, Zheng Xiaolong, Shen Yingshan, Pang Fengxiang, Chen Lixin, Li Weifeng, Yang Fan, Liu Shaojun, He Wei, Wei Qiushi. Trends in global research on bone and joint tuberculosis: bibliometrics and visual analysis [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(20): 3234-3239. |

| [12] | Qin Haikuo, Luo Shixing. Correlation of cortical bone thickness and X-ray gray value in different planes of proximal femur with brittle fracture of female hip [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(18): 2867-2872. |

| [13] | Wu Yuhang, Zheng Liqin, Zhang Biao, Li Fan, Chen Xinmin, Li Musheng, Zheng Yongze, Lin Ziling. Compression fracture simulation of osteoporotic trabecular bone in ovariectomized rats [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(15): 2387-2392. |

| [14] | Huang Tianji, Yang Shengdong, Lin Hao, Zhang Chunyang, Deng Zhongqi, Zhong Weiyang, Luo Xiaoji. Mapping knowledge domains of bibliometrics regarding percutaneous vertebroplasty and percutaneous kyphoplasty based on VOSviewer [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(15): 2410-2417. |

| [15] | Qu Renfei, Mai Yuying, Chen Xiaowei, Hu Huanying, Chen Guozhi, Li Dongdong, Liao Hongbing. Relationship between lactic acid concentration and osteoclast differentiation of mouse monocytes [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(14): 2177-2183. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||