Chinese Journal of Tissue Engineering Research ›› 2019, Vol. 23 ›› Issue (28): 4522-4528.doi: 10.3969/j.issn.2095-4344.1471

Previous Articles Next Articles

Contact pressure of knee prosthesis under different loads with deviation angles by finite element analysis

Xiang Changxin1, Ji Binping2, Chen Weiyi1, Wang Changjiang3, Guo Yuan1

- 1College of Biomedical Engineering, Taiyuan University of Technology, Taiyuan 030024, Shanxi Province, China; 2Shanxi Huajin Orthopaedic Hospital, Taiyuan 030024, Shanxi Province, China; 3College of Engineering and Information, University of Sussex, Brighton, BNI 9RH, UK

-

Online:2019-10-08Published:2019-10-08 -

Contact:Chen Weiyi, Professor, Doctoral supervisor, College of Biomedical Engineering, Taiyuan University of Technology, Taiyuan 030024, Shanxi Province, China -

About author:Xiang Changxin, Master, College of Biomedical Engineering, Taiyuan University of Technology, Taiyuan 030024, Shanxi Province, China -

Supported by:the National Natural Science Foundation of China, No. 11472185 (to GY)| the National Natural Science Foundation of China, No. 11772214 (to WCJ)

CLC Number:

Cite this article

Xiang Changxin, Ji Binping, Chen Weiyi, Wang Changjiang, Guo Yuan. Contact pressure of knee prosthesis under different loads with deviation angles by finite element analysis[J]. Chinese Journal of Tissue Engineering Research, 2019, 23(28): 4522-4528.

share this article

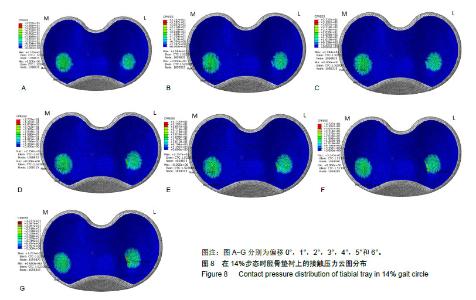

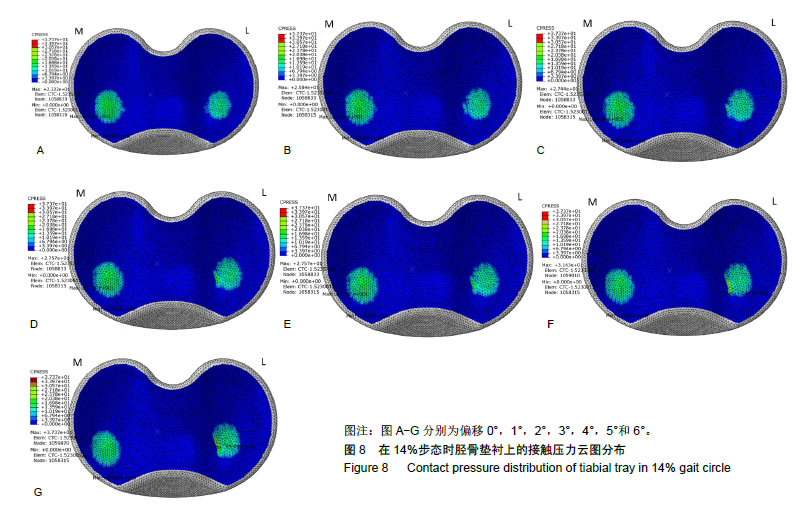

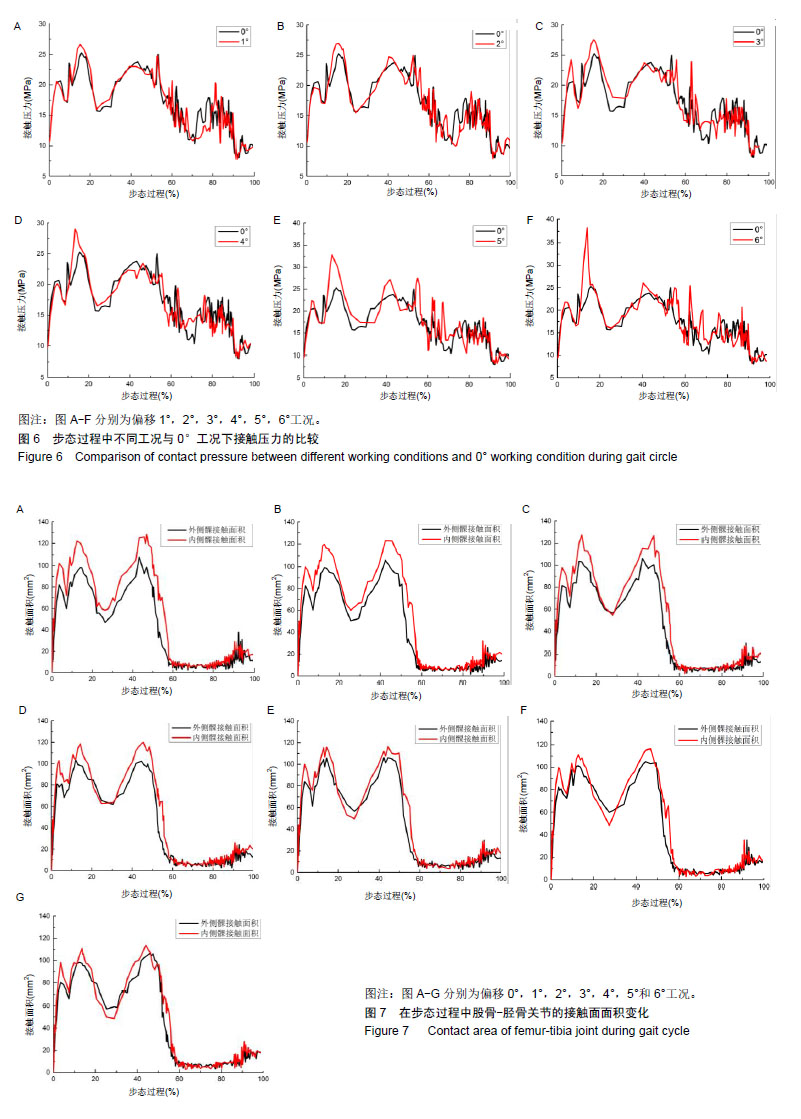

采用上述方法使用Abaqus软件进行有限元模拟分析。在步态过程中,将轴向载荷相对于中立位分别偏移0°,1°,2°,3°,4°,5°与6°形成7种不同工况,得到不同工况下的接触压力,面积与位置的变化。 2.1 接触压力 在步态过程中,不同工况下的胫骨垫衬上接触压力变化见图6。此文在0°工况下的接触压力最大值为22.92 MPa,这与Gruionu等[33]的研究结果一致,表明该有限元模型的准确性,接触压力的最大值出现在高分子聚乙烯垫衬内侧髁。此次研究采用与Halloran等[25]相同的步态数据,其研究表明在步态过程进行到44%和55%时,接触压力分别为20 MPa和19.1 MPa。同样工况下,此次研究得到的接触压力分别为22.60 MPa和18.64 MPa,此文的中0°工况下接触压力曲线和Halloran等[25]接触压力曲线在趋势上相同,都是在步态过程进行到14%与44%时到达2次峰值,进一步证明了模拟结果的有效性。通过对比曲线,可以得到在步态周期进行到达14%时,不同工况下的胫骨垫衬上的接触压力均达到最大值,0°,1°,2°,3°,4°,5°和6°工况下,其接触压力最大值分别为22.92 MPa,25.84 MPa,27.44 MPa,27.56 MPa,29.67 MPa,33.06 MPa和37.37 MPa。当步态过程达到摆动期后,不同工况下的接触压力都随步态的进行呈现波动性变化。通过对比其他工况和0°工况的接触压力曲线,可以发现,在步态过程中轴向载荷偏移角度的增大会使胫骨垫衬上接触压力明显增大。 2.2 接触面积 在步态过程中,不同工况下胫骨垫衬与股骨假体内外侧髁的接触面积变化见图7。由图可知,在步态过程中的站立期(0-60%),在0°工况下胫骨垫衬与内侧髁的接触面积大于其与外侧髁的接触面积,胫骨垫衬与膝关节假体内外侧髁的接触面积随步态过程的进行而呈现明显变化。发现在0°工况和1°工况下接触面积结果相似,当偏移角度达到3°以上时,同一个工况下在步态进程从20%-30%时,外侧髁与胫骨垫衬的接触面积会逐渐大于内侧髁与胫骨垫片的接触面积。在步态站立期,0°工况下外侧髁与胫骨垫衬接触面积的最大值为108.80 mm2,最小值为46.77 mm2;内侧髁与胫骨垫衬接触面积的最大值为128.41 mm2,最小值为58.28 mm2。6°工况下外侧髁与胫骨垫衬接触面积的最大值为106.52 mm2,最小值为57.17 mm2;内侧髁与胫骨垫衬接触面积的最大值113.62 mm2,最小值为48.62 mm2。"

| [1]Goudie EB, Robinson C, Walmsley P, et al. Changing trends in total knee replacement. Eur J Orthop Surg Traumatol. 2017;27(4):539-544.[2]Nam D, Mcarthur BA, Cross MB, et al. Patient-specific instrumentation in total knee arthroplasty: a review. J Knee Surg. 2012;25(3):213-220.[3]Noble PC, Conditt MA, Cook KF, et al. The John Insall Award: Patient expectations affect satisfaction with total knee arthroplasty. Clin Orthop Relat Res. 2006;452(452):35-43.[4]Massin P. How does total knee replacement technique influence polyethylene wear. Orthop Traumatol Surg Res. 2017; 103(1):S21.[5]Werner FW, Ayers DC, Maletsky LP, et al. The effect of valgus/varus malalignment on load distribution in total knee replacements. J Biomech. 2005;38(2):349-355.[6]Martinelli N, Baretta S, Pagano J, et al. Contact stresses, pressure and area in a fixed-bearing total ankle replacement: a finite element analysis. BMC Musculoskeletal Disorders. 2017;18(3):2473011417S0002.[7]Cerquiglini A, Henckel J, Hothi HS, et al. Computed tomography techniques help understand wear patterns in retrieved total knee arthroplasty. J Arthroplasty. 2018;33(9):3030-3037.[8]Villa TMF, Gastaldi D, Colombo M, et al. Contact stresses and fatigue life in a knee prosthesis: comparison between in vitro measurements and computational simulations. J Biomech. 2004;37(1):45-53.[9]Goswami T. Knee implants-Review of models and biomechanics. Mater Des. 2009;30(2):398-413.[10]Bartel DL, Rawlinson JJ, Burstein AH, et al. Stresses in polyethylene components of contemporary total knee replacements. Clin Orthop Relat Res. 1995;317(317):76-82.[11]Collier JP, Mayor MB, Mcnamara JL, et al. Analysis of the Failure of 122 Polyethylene Inserts From Uncemented Tibial Knee Components. Clin Orthop Relat Res. 1991;273(273):232-242.[12]Stukenborgcolsman C, Ostermeier S, Hurschler C, et al. Tibiofemoral contact stress after total knee arthroplasty: comparison of fixed and mobile-bearing inlay designs. Acta Orthopaedica Scandinavica. 2002; 73(6):638-646.[13]Sathasivam S, Walker PS. Computer model to predict subsurface damage in tibial inserts of total knees. J Orthop Res. 2010;16(5):564.[14]莫富灏,杜敏,刘傥,等. 肿瘤型膝关节置换后股骨-假体-胫骨复合体生物力学响应[J]. 医用生物力学,2016,31(3):235-239.[15]Woiczinski M, Steinbrück A, Weber P, et al. Development and validation of a weight-bearing finite element model for total knee replacement. Comput Methods Biomech Biomed Engin. 2016;19(10): 1033-1045. [16]Nakamura S , Tian Y , Tanaka Y , et al. The effects of kinematically aligned total knee arthroplasty on stress at the medial tibia. Bone Joint Res. 2017;6(1):43-51.[17]Young SW, Koh CK, Ravi S, et al. Total knee arthroplasty in the 21st century: why do they fail? a fifteen-year analysis of 11, 135 knees. Orthop J Sports Med. 2017;5(5 suppl5):2325967117S0020.[18]Barbour PS, Barton DC, Fisher J. The influence of stress conditions on the wear of UHMWPE for total joint replacements. J Mater Sci Mater Med. 1997;8(10):603.[19]郭媛,张绪树,安美文,等. 日常运动时内翻人工膝关节接触压力的有限元分析[J]. 太原理工大学学报,2014,45(3):358-362.[20]Shi JF. Finite element analysis of total knee replacement considering gait cycle load and malalignment. Quaternary Sci. 2007;27(5): 870-879.[21]Li X, Wang C, Guo Y, et al. An approach to developing customized total knee replacement implants. J Health Eng. 2017; 2017(8):1-8.[22]Munzinger UK , Wyss U , Boldt JG , et al. Basic Science, Design, and Materials[M]// Primary Knee Arthroplasty. Springer Berlin Heidelberg, 2004.[23]Teo A, Mishra A, Park I, et al. Polymeric Biomaterials for Medical Implants & Devices. Acs Biomat Sci Eng. 2016; 2(4): 454-472.[24]张绪树,郭媛,安美文,等. 不同运动状态下国产人工膝关节接触压力分布有限元分析[J]. 计算机辅助工程,2013,22(2):61-65.[25]Halloran JP, Petrella AJ, Rullkoetter PJ. Explicit finite element modeling of total knee replacement mechanics. J Biomech. 2005; 38(2):323-331.[26]李新宇,王长江,陈维毅. 一种新型膝关节假体在步态过程中接触应力的有限元仿真[J]. 医用生物力学,2017,32(6):494-499.[27]崔晓倩,王辅忠,张慧春. 膝关节股骨远端软骨硬化前后力学性能分析[J]. 医用生物力学,2015,30(1):25-29.[28]Crowninshield R, Pope MH, Johnson RJ. An analytical model of the knee. J Biomech. 1976;9(6):397-405.[29]王俊然,杜玮瑾,王长江,等. 有限元分析不同屈曲状态下胫-股关节的生物力学变化[J]. 中国组织工程研究,2018,22(31):4975-4981.[30]Taylor M, Barrett DS. Explicit finite element simulation of eccentric loading in total knee replacement. Clin Orthop Relat Res. 2003;414 (414):162-171.[31]ISO, ISO 14243-3: 2014, Implants for Surgery-Wear of Total Knee-Joint Prostheses, Loading and Displacement Parameters for Wear-Testing Machines with Displacement Control and Corresponding Environmental Conditions for Test, International Organization Environmental Standardization, London, UK, 2014.[32]Lafortune MA, Cavanagh PR, Iii HJS, et al. Three-dimensional kinematics of the human knee during walking. J Biomech. 1992;25(4): 347-357.[33]Gruionu LG, Gruionu G, Pastrama S, et al. Contact studies between total knee replacement components developed using explicit finite elements analysis.[C]// International Conference on Medical Image Computing & Computer-assisted Intervention. 2009.[34]赵奇,蒋垚. 人工膝关节假体设计新进展[J]. 中国组织工程研究,2010, 14(52):9838-9840.[35]邓海宁,曹轲飞,蒋仕雄. 全膝关节置换术假体的三维有限元生物力学分析[J]. 基因组学与应用生物学,2017,36(12):4992-4999.[36]Nguyen LCL, Lehil MS, Bozic KJ. Trends in total knee arthroplasty implant utilization. J Arthroplasty. 2015;30(5):739-742.[37]Nakamura S, Tian Y, Tanaka Y, et al. The effects of kinematically aligned total knee arthroplasty on stress at the medial tibia:A case study for varus knee. Bone Joint Res. 2017;6(1):43-51.[38]Vince KG. Why knees fail. J Arthroplasty. 2003;18(1):39-44.[39]Brockett C, Carbone S, Fisher J, et al. Influence of conformity on the wear of total knee replacement: An experimental study. Proc Inst Mech Eng H. 2018;232(2):127-134. [40]D'Lima DD, Chen PC, Jr CC. Polyethylene contact stresses, articular congruity, and knee alignment. Clin Orthop Relat Res. 2001;392(392): 232-238.[41]Rivière C, Iranpour F, Auvinet E, et al. Alignment options for total knee arthroplasty: A systematic review. Orthop Traumatol Surg Res. 2017; 103(7):1047.[42]Affatato S, Valigi MC, Logozzo S. Wear distribution detection of knee joint prostheses by means of 3d optical scanners. Materials. 2017;10(4):36.[43]Tarni?? D, Calafeteanu DM, Geonea ID, et al. Effects of malalignment angle on the contact stress of knee prosthesis components, using finite element method. Rom J Morphol Embryol. 2017;58(3):831-836. [44]Brockett CL, Abdelgaied A, Haythornthwaite T, et al. The influence of simulator input conditions on the wear of total knee replacements: An experimental and computational study. Proc Inst Mech Eng H. 2016; 230(5):429-439. |

| [1] | Xu Feng, Kang Hui, Wei Tanjun, Xi Jintao. Biomechanical analysis of different fixation methods of pedicle screws for thoracolumbar fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1313-1317. |

| [2] | Chen Xinmin, Li Wenbiao, Xiong Kaikai, Xiong Xiaoyan, Zheng Liqin, Li Musheng, Zheng Yongze, Lin Ziling. Type A3.3 femoral intertrochanteric fracture with augmented proximal femoral nail anti-rotation in the elderly: finite element analysis of the optimal amount of bone cement [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1404-1409. |

| [3] | Zhou Jihui, Li Xinzhi, Zhou You, Huang Wei, Chen Wenyao. Multiple problems in the selection of implants for patellar fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1440-1445. |

| [4] | Xu Yulin, Shen Shi, Zhuo Naiqiang, Yang Huilin, Yang Chao, Li Yang, Zhao Heng, Zhao Lu. Biomechanical comparison of three different plate fixation methods for acetabular posterior column fractures in standing and sitting positions [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 826-830. |

| [5] | Cai Qunbin, Zou Xia, Hu Jiantao, Chen Xinmin, Zheng Liqin, Huang Peizhen, Lin Ziling, Jiang Ziwei. Relationship between tip-apex distance and stability of intertrochanteric femoral fractures with proximal femoral anti-rotation nail: a finite element analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 831-836. |

| [6] | Song Chengjie, Chang Hengrui, Shi Mingxin, Meng Xianzhong. Research progress in biomechanical stability of lateral lumbar interbody fusion [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 923-928. |

| [7] | Liu Zhao, Xu Xilin, Shen Yiwei, Zhang Xiaofeng, Lü Hang, Zhao Jun, Wang Zhengchun, Liu Xuzhuo, Wang Haitao. Guiding role and prospect of staging and classification combined collapse prediction method for osteonecrosis of femoral head [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 929-934. |

| [8] | Xie Chongxin, Zhang Lei. Comparison of knee degeneration after anterior cruciate ligament reconstruction with or without remnant preservation [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 735-740. |

| [9] | Zhou Jihui, Li Xinzhi, Zhou You, Huang Wei, Chen Wenyao. Comparison of the advantages and disadvantages of multiple implants in treatment of traumatic dislocation of sternoclavicular joint [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 443-448. |

| [10] | Nie Shaobo, Li Jiantao, Sun Jien, Zhao Zhe, Zhao Yanpeng, Zhang Licheng, Tang Peifu. Mechanical stability of medial support nail in treatment of severe osteoporotic intertrochanteric fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 329-333. |

| [11] | Tan Jiachang, Yuan Zhenchao, Wu Zhenjie, Liu Bin, Zhao Jinmin. Biomechanical analysis of elastic nail combined with end caps and wire fixation for long oblique femoral shaft fractures [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 334-338. |

| [12] | Chen Lu, Zhang Jianguang, Deng Changgong, Yan Caiping, Zhang Wei, Zhang Yuan. Finite element analysis of locking screw assisted acetabular cup fixation [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 356-361. |

| [13] | Li Kun, Li Zhijun, Zhang Shaojie, Gao Shang, Sun Hao, Yang Xi, Wang Xing, Dai Lina . A 4-year-old child model of occipito-atlanto-axial joints established by finite element dynamic simulation [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3773-3778. |

| [14] | Shu Qihang, Liao Yijia, Xue Jingbo, Yan Yiguo, Wang Cheng. Three-dimensional finite element analysis of a new three-dimensional printed porous fusion cage for cervical vertebra [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3810-3815. |

| [15] | Sun Maji, Wang Qiuan, Zhang Xingchen, Guo Chong, Yuan Feng, Guo Kaijin. Development and biomechanical analysis of a new anterior cervical pedicle screw fixation system [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3821-3825. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||