Chinese Journal of Tissue Engineering Research ›› 2019, Vol. 23 ›› Issue (30): 4787-4792.doi: 10.3969/j.issn.2095-4344.1404

Previous Articles Next Articles

Finite element analysis and demonstration of scaffold material stacking

- 1Tianjin First Central Hospital, Tianjin 300192, China; 2Institute of Medical Equipment, PLA Academy of Military Medical Sciences, Tianjin 300161, China; 3Department of Orthopedics, General Hospital, Tianjin Medical University, Tianjin 300052, China

-

Received:2019-04-24Online:2019-10-28Published:2019-10-28 -

Contact:Li Hui, Chief physician, Department of Orthopedics, General Hospital, Tianjin Medical University, Tianjin 300052, China -

About author:Sun Kai, Master, Tianjin First Central Hospital, Tianjin 300192, China

CLC Number:

Cite this article

Sun Kai, Li Ruixin, Li Hao, Li Dong, Li Hui. Finite element analysis and demonstration of scaffold material stacking[J]. Chinese Journal of Tissue Engineering Research, 2019, 23(30): 4787-4792.

share this article

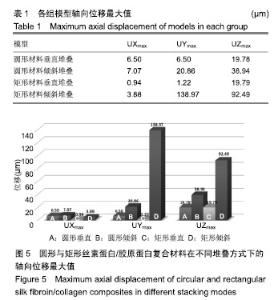

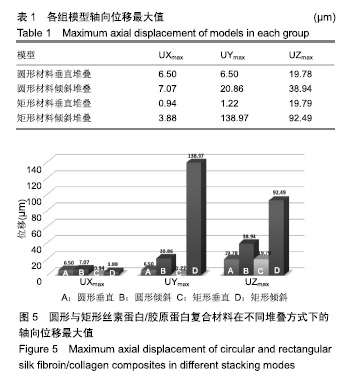

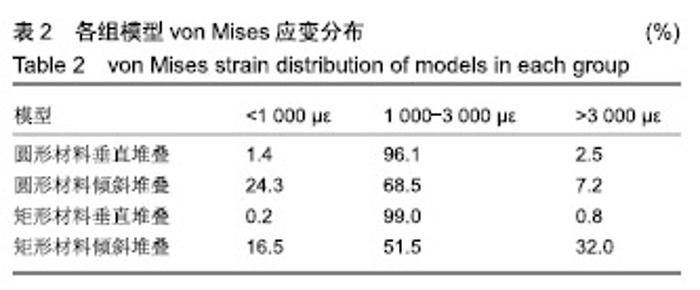

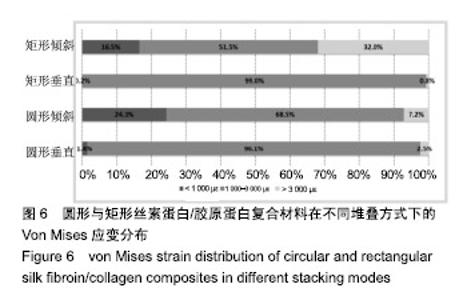

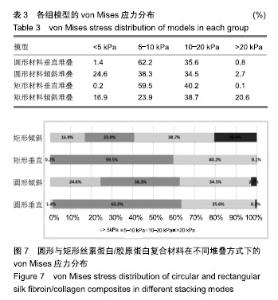

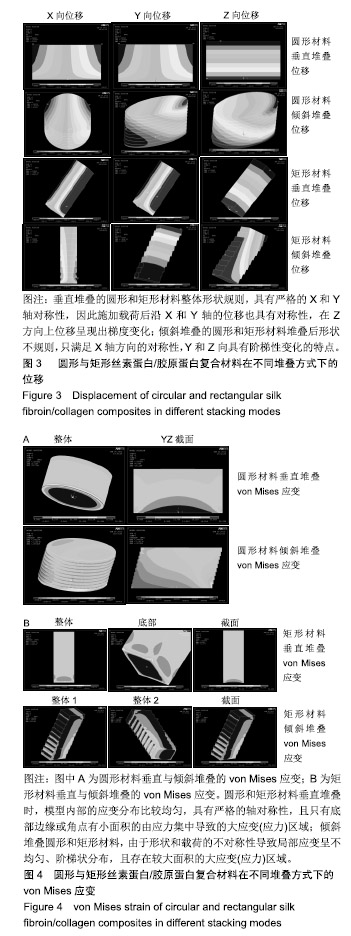

2.1 各组模型位移 有限元计算中的位移反映的是模型在载荷作用下空间位置的变化,实验输出的分别是模型沿X,Y,Z轴的位移分量,计算结果见图3。 由图可看出,垂直堆叠的圆形和矩形材料整体形状规则(堆叠后呈圆柱和长方体形状),具有严格的X和Y轴对称性,因此施加载荷后沿X和Y轴的位移也具有对称性,在Z方向上位移呈现出梯度变化;倾斜堆叠的圆形和矩形材料堆叠后形状不规则,只满足X轴方向的对称性,Y和Z向具有阶梯性变化的特点。 2.2 各组模型应变&应力特点 应变是一个衡量相对变形无量纲参数,反映模型局部变形情况,一个节点的应变值(绝对值)越大说明模型在该点处的变形越大;由于是线弹性材料,应力与应变呈正比(σ= Eε),变化趋势完全相同,应变计算结果见图4。 由图可见圆形和矩形材料垂直堆叠时,模型内部的应变分布比较均匀,具有严格的轴对称性,且只有底部边缘或角点有小面积的由应力集中导致的大应变(应力)区域;倾斜堆叠圆形和矩形材料,由于形状和载荷的不对称性导致局部应变呈不均匀、阶梯状分布,且存在较大面积的大应变(应力)区域。"

| [1]Beck EC,Barragan M,Tadros MH,et al.Detoamore. Approaching the compressive modulus of articular cartilage with decellularized cartilage-based hydrogel.Acta Biomater. 2016;38:9-105.[2]孙凯,年争好,徐成,等.丝素蛋白复合胶原蛋白支架的制备及性能研究[J].中国修复重建外科杂志, 2014,28(7):903-908.[3]Curl WW,Krome J,Gordon ES,et al.Cartilage injuries: A review of 31, 516 knee arthroscopies. Arthroscopy. 1997;13(4): 456-460.[4]Sun K,Li R,Jiang W,et al.Comparison of three-dimensional printing and vacuum freeze-dried techniques for fabricating composite scaffolds.Biochem Biophys Res Commun. 2016; 477(4):1085-1091.[5]Sun K,Li R,Li H,et al.Comparison of three- dimensional printing for fabricating silk fibroin-blended scaffolds.Int J Polym Mater Polym Biomater.2018;8(67):480-486.[6]Chen YN,Peng L,Liu T,et al.Poly(vinyl alcohol)-Tannic Acid Hydrogels with Excellent Mechanical Properties and Shape Memory Behaviors.ACS Appl Mater Interfaces. 2016;8(40): 27199-27206.[7]Sheu SY,Chen WS,Sun JS,et al.Biological characterization of oxidized hyaluronic acid/resveratrol hydrogel for cartilage tissue engineering.J Biomed Mater Res A. 2013;101(12): 3457-3466. [8]Fenn SL, Oldinski RA.Visible light crosslinking of methacrylated hyaluronan hydrogels for injectable tissue repair.J Biomed Mater Res B Appl Biomater. 2016;104(6): 1229-1236. [9]Zhou Y,Liang K,Zhao S,et al.Photopolymerized maleilated chitosan/methacrylated silk fibroin micro/nanocomposite hydrogels as potential scaffolds for cartilage tissue engineering.Int J Biol Macromol. 2018;108:383-390. [10]年争好,李晖,李瑞欣,等.纳米羟基磷灰石/胶原蛋白/丝素蛋白复合骨组织工程支架材料的生物相容性[J].中国组织工程研究, 2015,19(8):1149-1154.[11]年争好,孙凯,徐成,等.大鼠BMSCs成骨诱导及复合支架材料构建组织工程骨组织的研究[J].生物骨科材料与临床研究, 2015, 12(1):1-5.[12]Reyes R, Delgado A, Solis R,et al.Cartilage repair by local delivery of transforming growth factor-β 1 or bone morphogenetic protein-2 from a novel, segmented polyurethane/polylacticco-glycolic bilayered scaffold.J Biomed Mater Res A.2014;102(4):1110-1120.[13]Paul A,Manoharan V,Krafft D,et al.Nanoengineered biomimetic hydrogels for guiding human stem cell osteogenesis in three dimensional microenvironments.J Mater Chem B. 2016;4(20):3544-3554.[14]Kotecha M,Klatt D,Magin RL.Monitoring cartilage tissue engineering using magnetic resonance spectroscopy, imaging, and elastography.Tissue Eng Part B Rev.2013(19):470-484.[15]Aroni MAT,Spolidório LC,Andersen OZ,et al.Loading deproteinized bovine bone with strontium enhances bone regeneration in rat calvarial critical size defects.Clin Oral Investig.2018. doi: 10.1007/s00784-018-2588-6.[Epub ahead of print][16]Zheng G,Qiu G,Ge M,et al.Human adipose-derived mesenchymal stem cells alleviate obliterative bronchiolitis in a murine model via IDO.Respir Res.2017;18(1):119.[17]Trohatou O,Roubelakis MG. Mesenchymal stem /stromal cells in regenerative medicine: past,present,and future.Cell Reprogram.2017;19(4):217-224.[18]Shimomura K,Ando W,Moriguchi Y,et al. Next generation mesenchymal stem cell (MSC)- based cartilage repair using scaffold-free tissue engineered constructs generated with synovial mesenchymal stem cells.Cartilage.2015;6(2 Suppl): 13-29.[19]Holt BD,Wright ZM,Arnold AM,et al. Graphene oxide as a scaffold for bone regeneration.Wiley Interdiscip Rev Nanomed Nanobiotechnol.2017;9(3):e1437.[20]Wang K,Xu J,Cai J,et al. Serum levels of resistin and interleukin-17 are associated with increased cartilage defects and bone marrow lesions in patients with knee osteoarthritis. Mod Rheumatol. 2017;27(2):339-344. [21]Li F,Yao J,Tian H,et al.Correlations between traditional chinese medicine syndromes and IL-1,MMP and TIMP-1 in knee osteoarthritis.Int J Clin Exp Med. 2017;10(10): 14660-14666.[22]Duro-Castano A,Lim NH,Tranchant I,et al.In vivo imaging of MMP-13 activity using a specific polymer-FRET peptide conjugate detects early osteoarthritis and inhibitor efficacy. Adv Funct Mater.2018:1802738.[23]李乐,寇久社.三种质量浓度医用臭氧局部注射对兔膝OA行为 学及滑膜匀浆中IL-1?TNF-α水平的影响[J]. 解放军预防医学杂志,2018,36(1):77-79.[24]Yamasaki K,Nakasa T,Miyaki S,et al.Expression of microRNA- 146a in osteoarthritis cartilage. Arthritis Rheum. 2009;60(4):1035-1041.[25]Jones KJ,Sheppard WL,Arshi A,et al. Articular cartilage lesion characteristic reporting is highly variable in clinical outcomes studies of the knee. Cartilage. 2018:1947603518756464.doi: 10.1177/1947603518756464.[Epub ahead of print].[26]Zhang X,Wu S,Naccarato T,et al. Regeneration of hyaline-like cartilage in situ with SOX9 stimulation of bone marrow-derived mesenchymal stem cells.PLoS One. 2017;12(6):e0180138.[27]Sasaki T,Akagi R,Akatsu Y,et al.The effect of systemic administration of G-CSF on a full-thickness cartilage defect in a rabbit model MSC proliferation as presumed mechanism:G-CSF for cartilage repair.Bone Joint Res. 2017;6(3):123-131. [28]Chang YH,Liu HW,Wu KC,et al.Mesenchymal stem cells and their clinical applications in osteoarthritis.Cell Transplant. 2016;25:937-950.[29]Yoshimura H,Muneta T,Nimura A,et al.Comparison of rat mesenchymal stem cells derived from bone marrow,synovium,periosteum,adipose tissue,and muscle. Cell Tissue Res.2007;327(3):449-462.[30]Tao SC,Yuan T,Zhang YL,et al.Exosomes derived from miR-140 - 5p-overexpressing human synovial mesenchymal stem cells enhance cartilage tissue regeneration and prevent osteoarthritis of the knee in a rat model. Theranostics. 2017; 7(1):180-195.[31]Zhang S,Chuah SJ,Lai RC,et al.MSC exosomes mediate cartilage repair by enhancing proliferation,attenuating apoptosis and modulating immune reactivity. Biomaterials. 2017;156:16-27.[32]Toh WS,Lai RC,Hui JHP,et al.MSC exosome as a cell-free MSC therapy for cartilage regeneration:implications for osteoarthritis treatment.Semin Cell Dev Biol.2017;67:56-64.[33]Yubo M,Yanyan L,Li L,et al.Clinical efficacy and safety of mesenchymal stem cell transplantation for osteoarthritis treatment: A meta-analysis.PLoS One.2017;12(4):e0175449. [34]Paek HJ,Kim C,Tuan RS. Stem cell-based repair and regeneration of articular cartilage. J Stem Cell Res Ther. 2017;2(6):177-182. |

| [1] | Chen Xinmin, Li Wenbiao, Xiong Kaikai, Xiong Xiaoyan, Zheng Liqin, Li Musheng, Zheng Yongze, Lin Ziling. Type A3.3 femoral intertrochanteric fracture with augmented proximal femoral nail anti-rotation in the elderly: finite element analysis of the optimal amount of bone cement [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1404-1409. |

| [2] | Wang Debin, Bi Zhenggang. Related problems in anatomy mechanics, injury characteristics, fixed repair and three-dimensional technology application for olecranon fracture-dislocations [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1446-1451. |

| [3] | Zou Gang, Xu Zhi, Liu Ziming, Li Yuwan, Yang Jibin, Jin Ying, Zhang Jun, Ge Zhen, Liu Yi. Human acellular amniotic membrane scaffold promotes ligament differentiation of human amniotic mesenchymal stem cells modified by Scleraxis in vitro [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(7): 1037-1044. |

| [4] | Song Chengjie, Chang Hengrui, Shi Mingxin, Meng Xianzhong. Research progress in biomechanical stability of lateral lumbar interbody fusion [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 923-928. |

| [5] | Liu Zhao, Xu Xilin, Shen Yiwei, Zhang Xiaofeng, Lü Hang, Zhao Jun, Wang Zhengchun, Liu Xuzhuo, Wang Haitao. Guiding role and prospect of staging and classification combined collapse prediction method for osteonecrosis of femoral head [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 929-934. |

| [6] | Cai Qunbin, Zou Xia, Hu Jiantao, Chen Xinmin, Zheng Liqin, Huang Peizhen, Lin Ziling, Jiang Ziwei. Relationship between tip-apex distance and stability of intertrochanteric femoral fractures with proximal femoral anti-rotation nail: a finite element analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 831-836. |

| [7] | Li Wenjing, Li Haobo, Liu Congna, Cheng Dongmei, Chen Huizhen, Zhang Zhiyong. Comparison of different bioactive scaffolds in the treatment of regenerative pulp of young permanent teeth [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 499-503. |

| [8] | Li Chenjie, Lü Linwei, Song Yang, Liu Jingna, Zhang Chunqiu. Measurement and statistical analysis of trabecular morphological parameters of titanium alloy peri-prosthesis under preload [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 516-520. |

| [9] | Zhou Jihui, Yao Meng, Wang Yansong, Li Xinzhi, Zhou You, Huang Wei, Chen Wenyao. Influence of novel nanoscaffolds on biological behaviors of neural stem cells and the related gene expression [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 532-536. |

| [10] | Zhang Guomei, Zhu Jun, Hu Yang, Jiao Hongwei. Stress of three-dimensional finite element models of E-MAX porcelain inlay [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 537-541. |

| [11] | Ma Zhijie, Li Jingyu, Cao Fang, Liu Rong, Zhao Dewei. Influencing factors and biological property of novel biomedical materials: porous silicon carbide coated with bioactive tantalum [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 558-563. |

| [12] | Liu Liu, Zhou Qingzhu, Gong Zhuo, Liu Boyan, Yang Bin, Zhao Xian. Characteristics and manufacturing techniques of collagen/inorganic materials for constructing tissue-engineered bone [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 607-613. |

| [13] | Ye Haimin, Ding Linghua, Kong Weihao, Huang Zutai, Xiong Long. Role and mechanism of hierarchical microchanneled bone scaffolds in promoting osteogenesis and angiogenesis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 621-625. |

| [14] | Chen Jiana, Qiu Yanling, Nie Minhai, Liu Xuqian. Tissue engineering scaffolds in repairing oral and maxillofacial soft tissue defects [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 644-650. |

| [15] | Zhang Yu, Feng Shuo, Yang Zhi, Zhang Ye, Sun Jianning, An Lun, Chen Xiangyang. Three-dimensional gait of patients with developmental dysplasia of hip undergoing total hip arthroplasty with high hip center [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 350-355. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||