Chinese Journal of Tissue Engineering Research ›› 2023, Vol. 27 ›› Issue (7): 1004-1011.doi: 10.12307/2023.078

Previous Articles Next Articles

Three-dimensional finite element analysis of stress distribution in different smooth collar implants

Sun Jiangwei, Wang Junxiang, Baibujiafu·Yellisi, Dai Huijuan, Nijati·Turson

- Department of Stomatology, The Second Affiliated Hospital of Xinjiang Medical University, Urumqi 830063, Xinjiang Uygur Autonomous Region, China

-

Received:2022-01-17Accepted:2022-03-07Online:2023-03-08Published:2022-07-18 -

Contact:Nijati·Turson, Chief physician, Associate professor, Department of Stomatology, The Second Affiliated Hospital of Xinjiang Medical University, Urumqi 830063, Xinjiang Uygur Autonomous Region, China -

About author:Sun Jiangwei, Master candidate, Department of Stomatology, The Second Affiliated Hospital of Xinjiang Medical University, Urumqi 830063, Xinjiang Uygur Autonomous Region, China -

Supported by:Natural Science Foundation of Xinjiang Uygur Autonomous Region, No. 2016D01C192 (to NT)

CLC Number:

Cite this article

Sun Jiangwei, Wang Junxiang, Baibujiafu·Yellisi, Dai Huijuan, Nijati·Turson. Three-dimensional finite element analysis of stress distribution in different smooth collar implants[J]. Chinese Journal of Tissue Engineering Research, 2023, 27(7): 1004-1011.

share this article

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

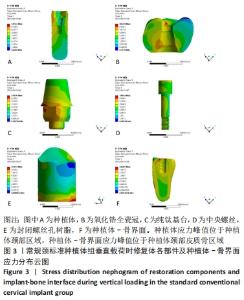

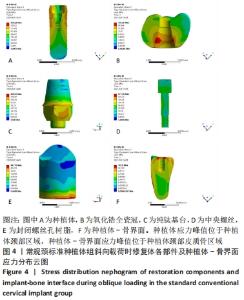

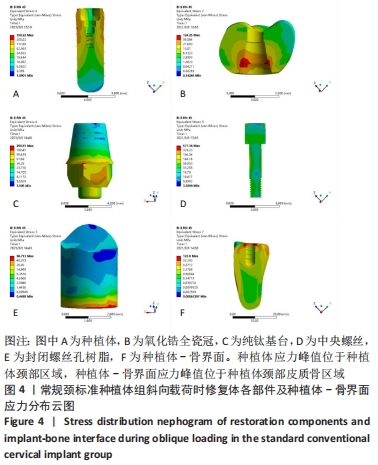

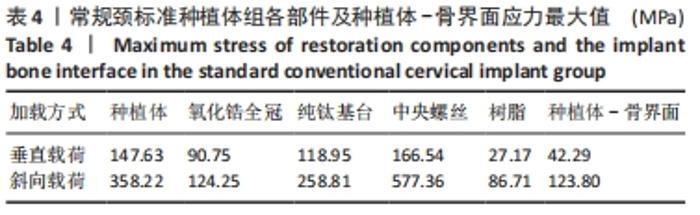

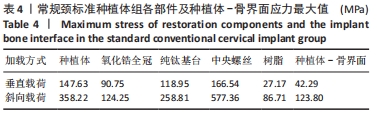

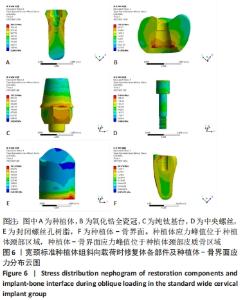

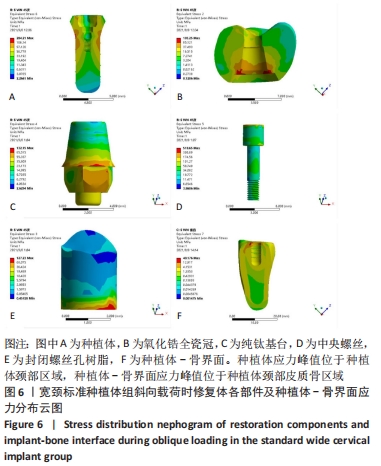

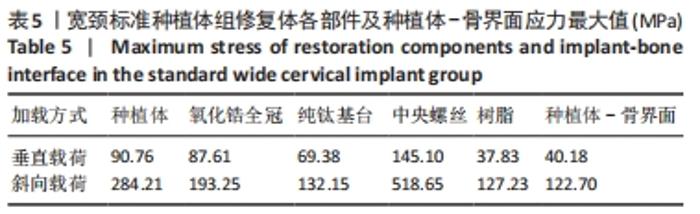

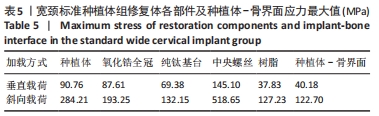

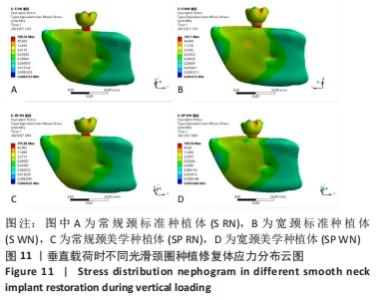

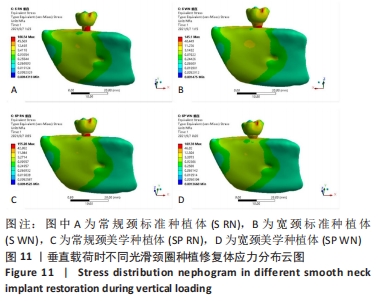

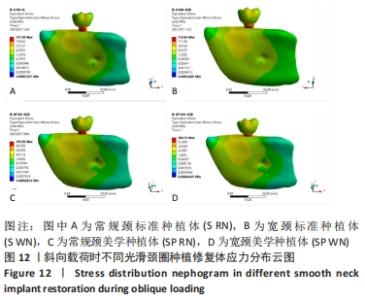

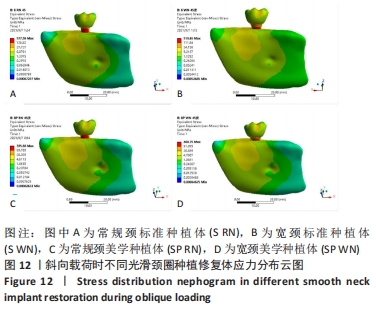

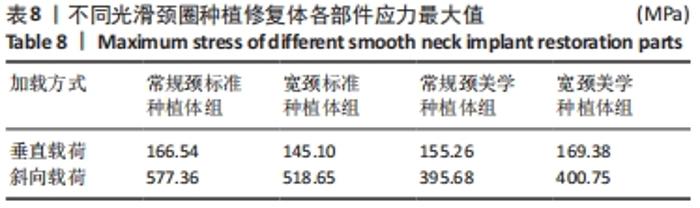

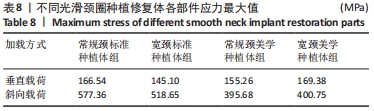

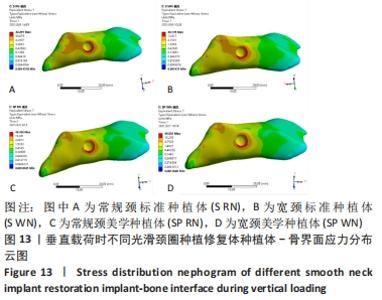

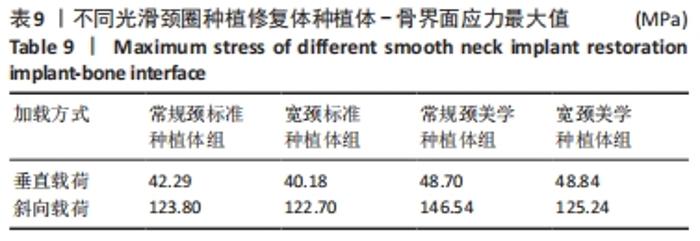

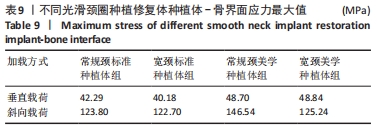

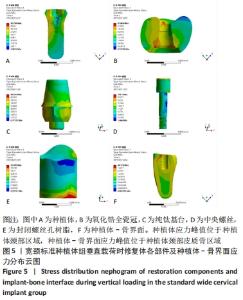

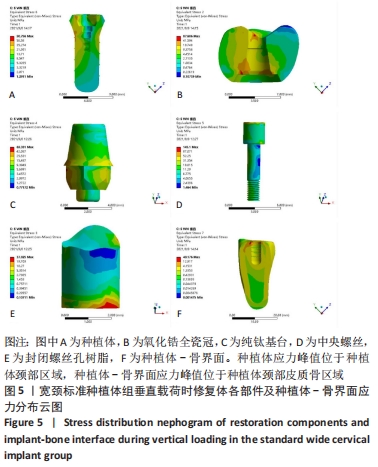

2.2.2 宽颈标准种植体组最大应力分布情况 应力分布云图显示,该型种植体应力峰值位于种植体颈部区域,种植体-骨界面应力峰值位于种植体颈部皮质骨区域,见图5,6。种植修复体各部件及种植体-骨界面在受到斜向载荷时所受应力最大值都大于垂直载荷,垂直加载下种植修复体各区域所受最大应力值大小顺序为:中央螺丝>种植体>氧化锆全冠>纯钛基台>种植体骨-界面>封闭螺丝孔树脂;斜向载荷下种植修复体各区域所受最大应力值大小顺序为:中央螺丝>种植体>氧化锆全冠>纯钛基台>封闭螺丝孔树脂>种植体-骨界面,此外该型种植体种植修复时应力峰值均出现在中央螺丝上,分别为145.10 MPa和518.65 MPa,见表5。"

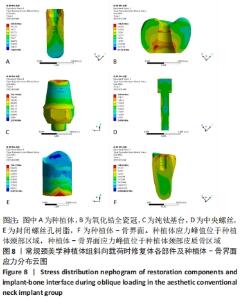

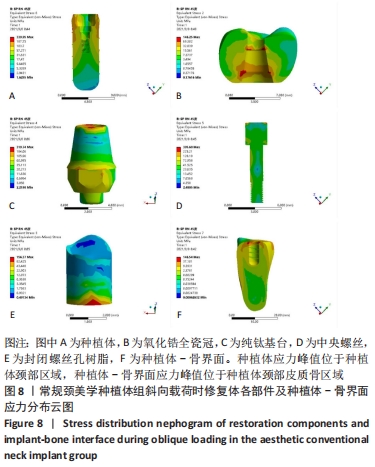

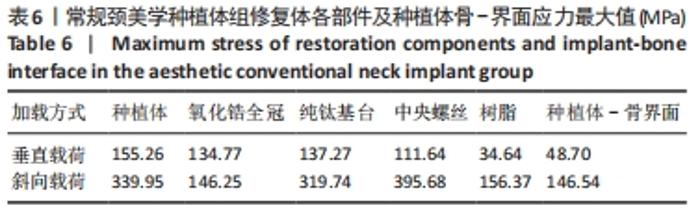

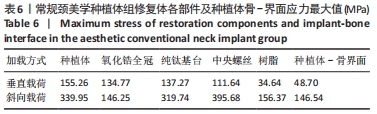

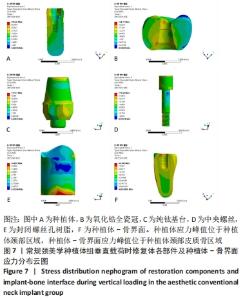

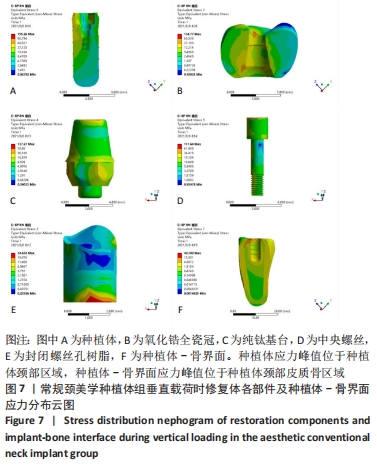

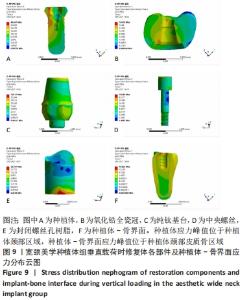

2.2.3 常规颈美学种植体组最大应力分布情况 应力分布云图显示,该型种植体应力峰值位于种植体颈部区域,种植体-骨界面应力峰值位于种植体颈部皮质骨区域,见图7,8。种植修复体各部件及种植体-骨界面在受到斜向载荷时所受应力最大值都大于垂直载荷,垂直加载下种植修复体各区域所受最大应力值大小顺序为:种植体>纯钛基台>氧化锆全冠>中央螺丝>种植体-骨界面>封闭螺丝孔树脂;斜向载荷下种植修复体各区域所受最大应力值大小顺序为:中央螺丝>种植体>纯钛基台封闭螺丝孔树脂>种植体-骨界面>氧化锆全冠,此外,该型种植体种植修复后在受到垂直载荷时应力峰值出现在种植体上,为155.26 MPa;在斜向载荷时应力峰值出现在中央螺丝上,为395.68 MPa,见表6。"

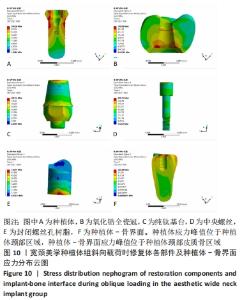

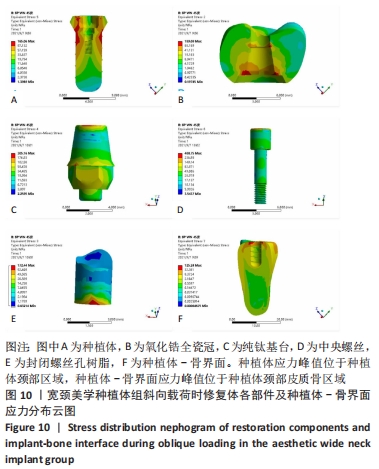

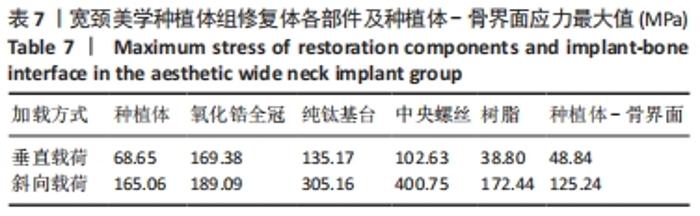

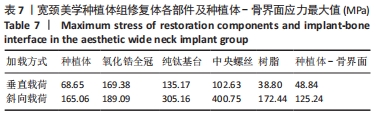

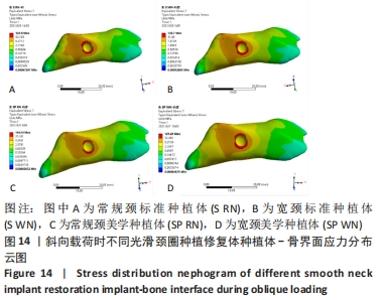

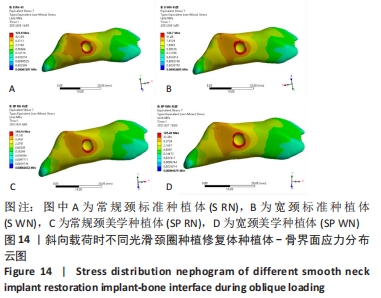

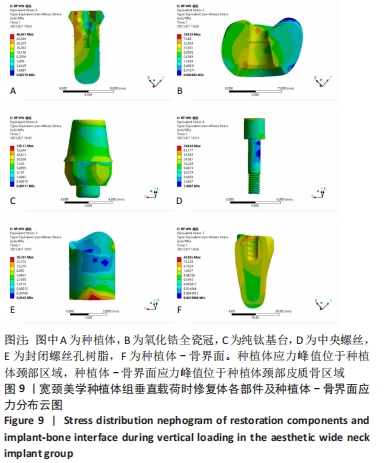

2.2.4 宽颈美学种植体组最大应力分布情况 应力分布云图显示,该型种植体应力峰值位于种植体颈部区域,种植体-骨界面应力峰值位于种植体颈部皮质骨区域,见图9,10。种植修复体各部件及种植体-骨界面在受到斜向载荷时所受应力最大值都大于垂直载荷,垂直加载下种植修复体各区域所受最大应力值大小顺序为:氧化锆全冠>纯钛基台>中央螺丝>种植体>种植体-骨界面>封闭螺丝孔树脂;斜向载荷下种植修复体各区域所受最大应力值大小顺序为:中央螺丝>纯钛基台>氧化锆全冠>封闭螺丝孔树脂>种植体>种植体-骨界面,此外,该型种植体种植修复后在受到垂直载荷时应力峰值出现在氧化锆全冠上,为169.38 MPa;在斜向载荷时应力峰值出现在中央螺丝上,为400.75 MPa,见表7。"

| [1] 安尼卡尔·安尼瓦尔,帕丽黛姆·图尔迪,阿迪力·麦木提敏,等.上颌前牙区不同种植修复体在不同咬合受力下的三维有限元分析[J].中国组织工程研究,2020,24(16):2531-2536. [2] 杜巧琳,顾新华.牙种植体形态结构设计的研究进展[J].口腔医学, 2021,41(5):475-480. [3] 赖漪娆,史俊宇,赖红昌.种植体光滑颈圈的临床应用[J].口腔医学,2021,41(8):746-750. [4] 李哲,秦博文,常晓峰,等.面开孔直径对种植修复系统及周围皮质骨影响的有限元分析[J].实用口腔医学杂志,2018,34(2):182-187. [5] 白布加甫·叶力思,热娜古丽·买合木提,艾孜买提江·赛依提,等.上颌中切牙联冠种植修复体在不同咬合方式中的应力分析[J].中国组织工程研究,2022,26(4):567-572. [6] FAVERANI LP, BARÃO VA, RAMALHO-FERREIRA G, et al. The influence of bone quality on the biomechanical behavior of full-arch implant-supported fixed prostheses. Mater Sci Eng C Mater Biol Appl. 2014;37: 164-170. [7] 哈雅楠.动态载荷下不同修复方式对后牙种植单冠应力分布影响的三维有限元分析[D].济南:山东大学,2019. [8] 施梦汝,谢伟丽,施武阁,等.柱形锥形种植体在不同种植深度的三维有限元研究[J].口腔医学,2019,39(7):577-580. [9] 黄耀文.不同材料修复下颌第一前磨牙楔状缺损的三维有限元分析[D].南昌:南昌大学,2020. [10] 陈俊良,李明霞,吕冬梅,等.迷你种植体支持的下颌覆盖义齿三维有限元分析[J].中国组织工程研究,2020,24(10):1491-1495. [11] HELAL MA, WANG Z. Biomechanical assessment of restored mandibular molar by endocrown in comparison to a glass fiber postretained conventional crown:3D finite element analysis. J Prosthodont. 2019; 28(9):988-996. [12] 赵楚翘,徐一驰,刘定坤,等.髓腔固位冠及桩核冠修复下颌第一磨牙大面积缺损的生物力学分析[J].口腔医学研究2018,34(5):513-517. [13] 王悦,郭振兴,谭乃文,等.种植失败病例风险因素的分析与探讨[J].中华口腔医学杂志,2017,52(8):510-512. [14] OGLE OE. Implant surface material,design and osseointegration. Dent Clin N Am. 2015;59(2):505-520. [15] YASUTAKE M, KUROSHIMA S, ISHIMOTO T, et al. The influence of bone quality on the biomechanical behavior of full-arch implant-supported fixed prostheses. MaterSci Eng C. 2014;37:164-170. [16] FROST HM. A 2003 update of bone physiology and Wolff’s Law for clinicians. Angle Orthod. 2004;74(1):3-15. [17] 王姝,李琼,金武龙.有限元法在口腔种植领域的研究进展[J].中华老年口腔医学杂志,2018,16(2):125-128. [18] MESSIAS A, NICOLAU P, GUERRA F. Titanium dental implants with different collar design and surface modifications: A systematic review on survival rates and marginal bone levels. Clin Oral Implants Res. 2019;30(1):20-48. [19] ROODABEH K, ALI H. Evaluation of Implant Collar Surfaces for Marginal Bone Loss: A Systematic Review and Meta-Analysis. Biomed Res Int. 2016;2016:1-10. [20] SÁNCHEZ-SILES M, MUOZ-CÁMARA D, SALAZAR-SÁNCHEZ N, et al. Incidence of peri-implantitis and oral quality of life in patients rehabilitated with implants with different neck designs: A 10-year retrospective study. J Craniomaxillofac Surg. 2015;43(10):2168-2174. [21] 范毅杰,李媛,胡晓文.不同颈部设计种植体在骨愈合期边缘骨变化的临床分析[J].中华口腔医学研究杂志,2018,12(3):169-175. [22] VALLES C, RODRÍGUEZ-CIURANA X, NART J, et al. Influence of Implant Neck Surface and Placement Depth on Crestal Bone Changes Around Platform-Switched Implants: A Clinical and Radiographic Study in Dogs. J Periodontol. 2017;88(11):1200-1210. [23] VALLES C, RODRIGUEZ-CIURANA X, MUNOZ F, et al. Influence of implant neck surface and placement depth on crestal bone changes and soft tissue dimensions around platform-switched implants: A histologic study in dogs. J Clin Periodontol. 2018;45(7):869-883. [24] 栗兴超,董福生,李向军,等.不同颈部结构钛人工牙种植体的骨结合性能研究[J].现代口腔医学杂志,2017,31(3):129-132. [25] WENG D, NAGATA M, LEITE CM, et al. Influence of microgap location and configuration on the periimplant bone morphology in submerged implants. An experimental study in dogs. Clin Oral Implan Res. 2010; 19(5):1141-1147. [26] ROMANOS GE, AYDIN E, GAERTNER K, et al. Long-Term Results after Subcrestal or Crestal Placement of Delayed Loaded Implants. Clin Implant Dent Relat Res. 2015;17(1):133-141. [27] ALOMRANI AN, HERMANN JS, JONES AA, et al. Influence of a machined collar on crestal bone changes around titanium implants: a histometric study in the canine mandible. Int J Oral Max Impl. 2005;20(5):677. [28] HARTMAN GA, COCHRAN DL. Initial implant position determines the magnitude of crestal bone remodeling. J Periodontol. 2004;75(4):572-577. [29] SCHWARZ F, HEGEWALD A, BECKER J. Impact of implant–abutment connection and positioning of the machined collar/microgap on crestal bone level changes: a systematic review. Clin Oral Implan Res. 2014;25(4):417-425. [30] 高健,赵守亮,周成杰.种植体直径-长度比的三维有限元应力分析[J].口腔颌面外科杂志,2014,24(5):364-369. [31] 聂秀吉,李淑娴,马宗民,等.种植体不同设计参数对下颌骨牙齿种植的影响[J].医用生物力学,2021,36(6):890-895. [32] 牛金磊,陈建宇,陈贤帅,等.种植体颈部微螺纹结构对种植稳定性影响的三维有限元分析[J].口腔颌面修复学杂志,2013,14(6):344-348. [33] HAN A, TSOI J, RODRIGUES FP, et al. Bacterial adhesion mechanisms on dental implant surfaces and the influencing factors. Int J Adhes Adhe. 2016;69:58-71. [34] 李彦.牙列缺损种植修复的咬合评估与设计[J].中华口腔医学杂志, 2016,51(4):219-223. [35] 陈江.咬合重建的点线面设计与种植风险防范[J].中华口腔医学杂志,2018,53(12):805-809. |

| [1] | Fang Xingyan, Tian Zhenli, Zhao Zheyi, Wen Ping, Xie Tingting. Effects of sodium arsenite on human umbilical vein endothelial cell injury and sphingosine kinases 1/sphingosine 1-phosphate signaling axis [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(在线): 1-7. |

| [2] | Zhong Yizheng, Huang Peizhen, Cai Qunbin, Zheng Liqin, He Xingpeng, Dong Hang. Microstructural indexes that determine the trabecular bone maximum stress of micro-finite element models [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1313-1318. |

| [3] | Tang Huiyu, Hou Biao, Xia Xiaodan, Xiang Wei, Xie Songlin. Effect of mechanical tension stress on arterial vessels after limb osteotomy in rabbits [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1422-1426. |

| [4] | Peng Zhixin, Yan Wengang, Wang Kun, Zhang Zhenjiang. Finite element analysis and structural optimization design of 3D printed forearm braces [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1340-1345. |

| [5] | Wu Tianliang, Tao Xiuxia, Xu Hongguang. Influence of different bone mineral densities on cage subsidence after stand-alone oblique lateral interbody fusion: three-dimensional finite element analysis [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1352-1358. |

| [6] | Liu Jinyu, Zhang Hanshuo, Cui Hongpeng, Pan Lingzhi, Zhao Boran, Li Fei, Ding Yu. Finite element biomechanical analysis of minimally invasive treatment of cervical spondylotic myelopathy and accurate exercise rehabilitation [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1359-1364. |

| [7] | He Yujie, Kang Zhijie, Xue Mingming, Jin Feng, Li Zhijun, Wang Xing, Xu Yangyang, Gao Mingjie, Li Jiawei, Li Xiaohe, Wang Haiyan. Finite element analysis of transarticular screw fixation of adolescent thoracic vertebra [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1365-1370. |

| [8] | Wen Xinghua, Ding Huanwen, Cheng Kai, Yan Xiaonan, Peng Yuanhao, Wang Yuning, Liu Kang, Zhang Huiwu. Three-dimensional finite element model analysis of intramedullary nailing fixation design for large femoral defects in Beagle dogs [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1371-1376. |

| [9] | Dang Yi, Du Chengyan, Yao Honglin, Yuan Nenghua, Cao Jin, Xiong Shan, Zhang Dingmei, Wang Xin. Hormonal osteonecrosis and oxidative stress [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1469-1476. |

| [10] | Zhu Lin, Gu Weiping, Wang Can, Chen Gang. Biomechanical analysis of All-on-Four and pterygomaxillary implants under different maxillary bone conditions [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(7): 985-991. |

| [11] | Jiang Yifang, Cai Qimin, Chu Zhengyi, Qin Min, Shen Yurong, Gu Yuanping. Simulation analysis of stress distribution of NRT FILES in curved root canals [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(7): 1038-1042. |

| [12] | Li Huiqin, Wang Chunjuan, Wang Yu, Wang Weifeng, Chen Dinggen, Li Na. Clear aligner orthodontic therapy of rotated mandibular teeth with different shapes: a three-dimensional finite element analysis [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(7): 1050-1054. |

| [13] | Liu Qing, Song Hao, Du Chengfei, Sun Yanfang, Li Kun, Zhang Chunqiu. Mechanical behavior of lumbar disc rupture under quasi-static compression [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(4): 493-499. |

| [14] | Liu Qinghua, Cai Yongqiang, Jin Feng, Yu Jinghong, Wang Haiyan, Zhang Yunfeng, Wang Lidong, Li Jiawei, Wang Xing, He Yujie, Dai Lina, Wang Jianzhong, Wu Chao, Tong Ling, Kang Zhijie, Li Zhijun, Li Xiaohe. Finite element model of the 12-year-old child whole cervical spine: establishment and validity verification based on CT data [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(4): 500-504. |

| [15] | Lu Hui, Wu Qimei, Liu Rong. Finite element analysis and application of unilateral and bilateral bone-filling mesh container in treatment of osteoporotic vertebral compression fracture [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(3): 391-397. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||