[1] 周锦春,郭敦明,王青,等.股骨颈骨折闭合复位加压螺纹钉内固定术后股骨头坏死多中心多因素相关分析[J].中华骨科杂志, 2013,33(5):549-554.

[2] 孙友强,陈雷雷,刘予豪,等.股骨颈骨折内固定后股骨头坏死发生研究现状[J].中国组织工程研究,2017,21(19):3095-3101.

[3] 吴新宝,杨明辉.老年髋部骨折诊疗专家共识(2017)[J].中华创伤骨科杂志,2017,19(11):921-927.

[4] 庄至坤,许志庆,郭金花,等.中青年股骨颈骨折内固定术后股骨头坏死的相关因素[J].中国矫形外科杂志,2018,26(22):2044-2049.

[5] OÑATIVIA IJ, SLULLITEL PA, DIAZ DILERNIA F, et al. Outcomes of nondisplaced intracapsular femoral neck fractures with internal screw fixation in elderly patients: a systematic review. Hip Int. 2018;28: 18-28.

[6] YE CY, LIU A, XU MY, et al. Arthroplasty versus Internal Fixation for Displaced Intracapsular Femoral Neck Fracture in the Elderly: Systematic Review and Meta-analysis of Short- and Long-term Effectiveness. Chin Med J (Engl). 2016;129:2630-2638.

[7] 俞光荣,夏江.股骨颈骨折的手术治疗策略[J].中华创伤骨科杂志, 2011,13(7):601-606.

[8] 张长青,黄轶刚.股骨颈骨折的治疗理念与新技术[J].中华创伤骨科杂志,2016,18(8):645-646.

[9] 张成宝,马信龙,马剑雄,等.股骨颈骨折空间移位程度与内固定术后股骨头缺血性坏死的相关性研究[J].中华创伤骨科杂志, 2016,18(2):133-137.

[10] 韦积华,韦庆军,程建文,等.计算机导航系统在股骨颈骨折经皮空心螺钉内固定中应用的实验研究[J].广西医科大学学报,2012, 29(1):31-33.

[11] 王军强,樊瑜波.计算机辅助骨科手术技术将改善股骨颈骨折治疗[J].中国骨伤,2018,31(2):99-102.

[12] 吴磊,吴京亮,张丛笑,等.计算机导航辅助空心钉内固定治疗无移位股骨颈骨折[J].中国骨与关节损伤杂志,2015,30(8):792-793.

[13] 张英泽.股骨颈骨折治疗方案选择策略与进展[J].中国骨伤,2015, 28(9):781-783.

[14] 黄晓文,公茂琪,查晔军,等.早期快速闭合复位空心钉内固定治疗高龄股骨颈骨折的临床研究[J].中华老年骨科与康复电子杂志, 2017,3(1):4-10.

[15] 张英泽.老年股骨颈骨折诊治中的重要问题[J].中华老年骨科与康复电子杂志,2015,1(1):6-8.

[16] 邱旭升,戚晓阳,陈一心,等.空心加压螺钉治疗老年无移位型股骨颈骨折的长期随访研究[J].中华老年骨科与康复电子杂志, 2019,5(1):9-12.

[17] 郝申申,王延峰,刘志斌,等.3D打印导航模板辅助股骨颈骨折空心钉置入的应用价值[J].中国骨与关节损伤杂志,2018,33(4):384-386.

[18] NAKANISHI Y, HIRANAKA T, SHIRAHAMA M, et al. Ideal screw positions for multiple screw fixation in femoral neck fractures - Study of proximal femur morphology in a Japanese population. J Orthop Sci. 2018;23: 521-524.

[19] 梁会,何小健,陈农,等.Pauwels Ⅱ型后侧壁粉碎股骨颈骨折不同构型空心钉内固定的生物力学比较[J].中国骨与关节损伤杂志, 2018,33(10):1013-1016.

[20] 汤长华,王黎明,姚庆强,等.双头空心钉组合单头空心钉内固定治疗头下型股骨颈骨折[J].中国骨与关节损伤杂志,2017,32(3): 312-313.

[21] 鲍立杰,张志平,吴培斌.3D打印技术在骨科的研究及应用进展[J].中国矫形外科杂志,2015,23(4):325-327.

[22] 朱诗白,蒋超,叶灿华,等.3D打印技术在骨科领域的应用[J].中华骨质疏松和骨矿盐疾病杂志,2016,9(1):88-93.

[23] 许森赫,王金成,范丽雯,等.国内外3D打印在骨科的发展状况[J].中国实验诊断学,2018,22(2):367-370.

[24] 邓杨,周礼兵,廖洪溢,等. 3D打印组合式导板技术辅助内踝骨折复位及空心钉置入的初步疗效观察[J]. 生物骨科材料与临床研究, 2020,17(1): 22-25.

[25] 丁悦,罗剑锋,王臻,等. 个性化3D打印导向器空心钉固定股骨颈骨折[J]. 中国矫形外科杂志,2020,28(24):2213-2217.

[26] 王思哲,徐禛禛,邵文,等. 3D打印导向模板辅助下置入空心钉治疗股骨颈骨折的临床研究[J]. 骨科,2019,10(5):407-411.

[27] 阳宏奇,雷青,蔡立宏,等. 3D打印导板辅助空心螺钉内固定治疗不稳定性骨盆骨折[J]. 中国修复重建外科杂志,2018,32(2):145-151.

[28] 郑朋飞,唐凯,王黎明,等. 3D打印个体化手术导航模板在儿童股骨颈骨折中的应用[J]. 中华实用儿科临床杂志,2016,31(11): 863-866.

[29] 钟鸣亮,陈荣春,陈云生,等. 3D打印定位导板在齿状突骨折螺钉内固定中的应用研究[J]. 微创医学,2018,13(5):583-585.

[30] 盛晓磊,袁峰,李智多,等. 3D打印组合式导板辅助下颈椎前路椎弓根螺钉置入与徒手置钉的准确性对比[J].中国组织工程研究, 2017,21(3):406-411.

[31] 张洪涛,孔祥雪,史强,等. 3D 打印个体化导板在下肢成角畸形螺钉植入中的应用[J]. 实用骨科杂志,2016,22(5):467-469.

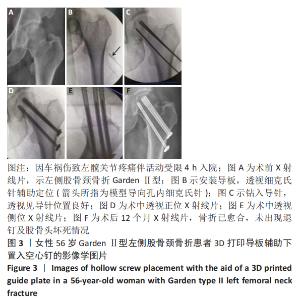

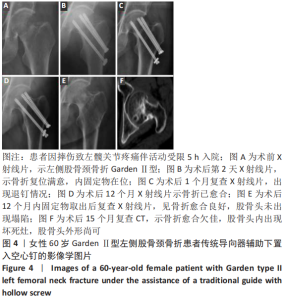

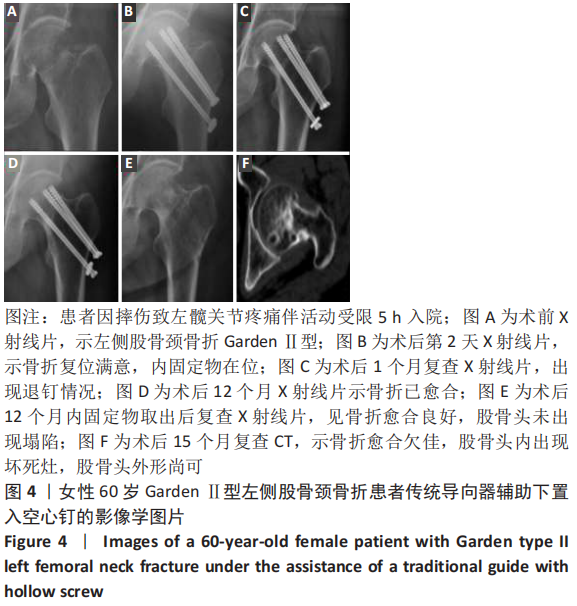

[32] 吴帆,王越,曹雷,等. 3D打印导向模板辅助技术在髋部骨折手术中的临床研究[J]. 创伤外科杂志,2021,23(1):15-19.

[33] 丁祥,李超,牛国旗, 等. 个体化3D打印导向模板辅助强直性脊柱炎颈椎椎弓根螺钉置入的实验研究[J]. 实用医学杂志,2020,36(8): 1072-1076. |