| [1] Zhang Z,Kuijer R,Bulstra SK,et al.The in vivo and in vitro degradation behavior of poly(trimethylene carbonate). Biomaterials. 2006;27(9): 1741-1748.[2] Zhu KJ,Hendren RW,Jensen K, et al.Synthesis, properties, and degradation of poly(1, 3-trimethylene carbonate). Macromolecules. 1991;24(8):1736-1740.[3] 杨立群,周群华,张巍,等.聚三亚甲基碳酸酯的研究进展[J].高分子通报, 2016,29(8):29-43.[4] 赵宁,张现军,李伟,等. 左旋聚乳酸羟基磷灰石生物材料与牙周膜细胞的生物相容性[J].中国组织工程研究, 2016,20(12):1732-1737.[5] 马晓妍,石淑先,夏宇正,等.聚乳酸及其共聚物的制备和降解性能[J].北京化工大学学报(自然科学版), 2004,31(1):51-56.[6] 胡露,魏坤,邹芬.聚乳酸-羟基乙酸共聚物/硅酸钙三维多孔骨组织工程支架的构建与性能[J].中国组织工程研究, 2016,20(47):6997-7005.[7] Albertsson AC,Eklund M.In vitro degradation of poly(trimethylene carbonate), poly(trimethylene carbonate-co-caprolactone), and poly(adipic anhydride).J Appl Polym Sci.1995;57(1):87-103.[8] 肖凯,郭颖志,顾忠伟.聚三亚甲基碳酸酯-丙交酯共聚物微球长效避孕体系的研究[J].中国计划生育学杂志, 2008,16(4):219-222.[9] 杨立群,张金哲,张巍,等.聚三亚甲基碳酸酯的改性研究[J].高分子通报, 2016,29(11):23-38.[10] Bat E,Kothman BH,Higuera GA, et al.Ultraviolet light crosslinking of poly(trimethylene carbonate) for elastomeric tissue engineering scaffolds. Biomaterials. 2010;31(33):8696-8705.[11] 韩雅如.完全生物可降解心血管支架用复合材料研究[D].上海:复旦大学, 2011.[12] Papenburg BJ,Schüller-Ravoo S,Bolhuis-Versteeg LA,et al.Designing porosity and topography of poly(1, 3-trimethylene carbonate) scaffolds. Acta Biomaterialia. 2009;5(9):3281-3294.[13] Pego AP,Poot AA,Grijpma DW,et al.Copolymers of trimethylene carbonate and ε-caprolactone for porous nerve guides: synthesis and properties.J Biomater Sci Polym Ed. 2001;12(1):35-53. [14] 邵国喜,焦晶雪,刘钦毅,等.聚乳酸-聚三亚甲基碳酸酯/GDNF导管对大鼠脊髓损伤区 GAP-43mRNA 表达的影响[J].中国实验诊断学, 2015, 19(2):198-201.[15] Fabre T,Schappacher M,Bareille R, et al.Study of a (trimethylenecarbonate-co-ε-caprolactone)polymer-Part 2: in vitro cytocompatibility analysis and in vivo ED1 cell response of a new nerve guide.Biomaterials.2001;22(22):2951-2958.[16] 裴香玲.恩诺沙星聚乳酸-聚三亚甲基碳酸酯的体内外降解和释药研究[D].兰州:甘肃农业大学,2007.[17] 吴雷刚,吴婧,侯瑞霞,等.他克莫司-聚三亚甲基碳酸酯药物洗脱支架涂层研究[J].功能材料,2011,42(11):1954-1957.[18] Pego AP,Poot AA,Grijpma DW, et al.In vitro degradation of trimethylene carbonate based (co)polymers. Macromol Biosci. 2002; 2(9):411-419.[19] 周群华,杨立群,张巍,等.聚三亚甲基碳酸酯的生物相容性研究[J].高分子通报,2016,29(6):71-77.[20] Yang LQ,Yang D,Guan YM,et al.Random copolymers based on trimethylene carbonate and ε‐caprolactone for implant applications: Synthesis and properties.J Appl Polym Sci. 2012;124(5):3714-3720.[21] Yang L,Li J,Meng S,et al.The in vitro and in vivo degradation behavior of poly (trimethylene carbonate-co-ε-caprolactone) implants. Polymer. 2014;55(20):5111-5124.[22] Yang L,Li J,Jin Y,et al. In vitro enzymatic degradation of the cross-linked poly (ε-caprolactone) implants.Polym Degrad Stab. 2015; 112:10-19.[23] Hou Z,Hu J,Li J,et al.The In Vitro Enzymatic Degradation of Cross-Linked Poly (trimethylene carbonate) Networks. Polymers. 2017; 9(11):605.[24] Yang L,Li J,Zhang W,et al.The degradation of poly (trimethylene carbonate) implants: the role of molecular weight and enzymes. Polym Degrad Stab.2015;122:77-87.[25] Chen B,Yin C,Cheng Y,et al.Using silk woven fabric as support for lipase immobilization: The effect of surface hydrophilicity/ hydrophobicity on enzymatic activity and stability. Biomass Bioenergy. 2012;39:59-66.[26] Chen GJ,Kuo CH,Chen CI,et al.Effect of membranes with various hydrophobic/hydrophilic properties on lipase immobilized activity and stability.J Biosci Bioeng. 2012;113(2):166-172.[27] Sun H,Mei L,Song C,et al.The in vivo degradation, absorption and excretion of PCL-based implant. Biomaterials. 2006;27(9):1735-1740. [28] 宋存先,王彭延.聚己内酯在体内的降解,吸收和排泄[J].生物医学工程学杂志,2000,17(1):25-28. [29] 於秋霞,朱光明,梁国正,等.聚 ε-己内酯的合成、性能及应用进展[J].高分子材料科学与工程,2004, 20(5):37-40. [30] 张金哲,周群华,杨立群,等.非生物降解型及生物降解型长效皮下埋植避孕剂的理论研究与应用进展[J].中国组织工程研究, 2017,21(22):3595-3601.[31] 刘春海.可生物降解皮下埋植避孕剂Capronor的临床研究[J].中国计划生育学杂志,1996,4(3): 187-189.[32] Marten E,Muller RJ,Deckwer WD. Studies on the enzymatic hydrolysis of polyesters I. Low molecular mass model esters and aliphatic polyesters. Polym Degrad Stab. 2003;80(3):485-501. |

.jpg)

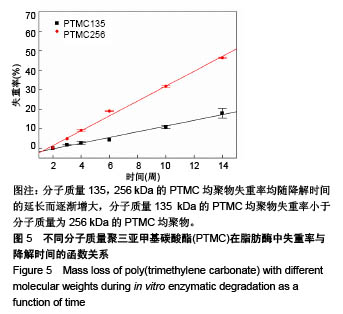

.jpg)