[1] BECK EC, BARRAGAN M, TADROS MH, et al. Approaching the compressive modulus of articular cartilage with decellularized cartilage-based hydrogel. Acta Biomater. 2016;1(38):94-105.

[2] 康嘉宇,吕建伟,赵志虎,等.骨软骨组织工程分层支架的研究进展[J].中华骨科杂志,2019,39(22):1413-1419.

[3] 孙凯,李瑞欣,范猛,等.3D打印丝素蛋白/胶原蛋白支架的制备及性能[J].中国组织工程研究,2017,21(2):280-285.

[4] 林祥龙.压缩载荷下人工关节软骨的构建及软骨缺损修复的研究[J].天津:天津理工大学,2019.

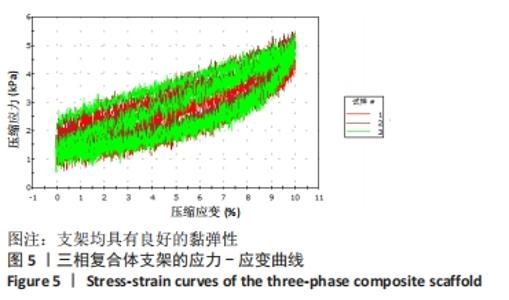

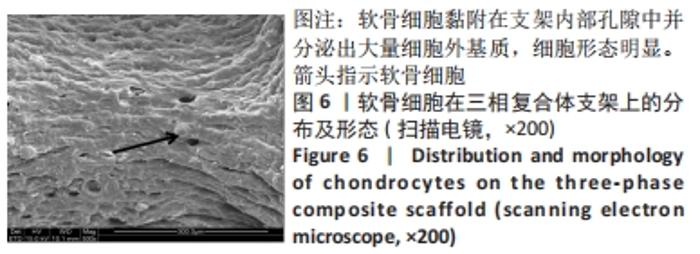

[5] 林祥龙,高丽兰,李瑞欣,等.压缩载荷下软骨细胞/复合支架的三维培养[J].中国组织工程研究,2019,23(10):1483-1488.

[6] 程威,张扬,宋秀钢,等.基于丝素/胶原/羟基磷灰石仿生骨材料的多维结构及其性能[J].医用生物力学,2019,34(6):623-630.

[7] SUN K, LI R, LI H, et al. Comparison of three- dimensional printing for fabricating silk fibroin-blended scaffolds. Int J Polym Mater Polym Biomater. 2018;8(67):480-486.

[8] 杨强,丁晓明,徐宝山,等.含软骨钙化层的仿生支架体内构建组织工程骨软骨[J].中华骨科杂志,2018,38(6):321-329.

[9] Fenn SL, OLDINSKI RA. Visible light crosslinking of methacrylated hyaluronan hydrogels for injectable tissue repair. Biomed Mater Res B Appl Biomater. 2016;104(6):1229-1236.

[10] ZHOU Y, LIANG K, ZHAO S, et al. Photopolyme rized maleilated chitosan/methacrylated silk fibroinmicro/nanocomposite hydrogels as potential scaffolds for cartilage tissue engineering. Int J Biol Macromol. 2018;108:383-390.

[11] KOH RH, JIN Y, KANG B, et al. Chondrogenically primed tonsil- derived mesenchymal stem cells encapsulated in riboflavin-induced photocrosslinking collagen-hyaluronic acid hydrgel for meniscus tissuerepairs. Acta Biomater. 2017;53(7):318-328.

[12] MORRISON RJ, NASSER HB, KASHLAN KN, et al. Co-culture of adipose-derived stem cells and chondrocytes on three-dimensionally printed bioscaffolds for craniofacial cartilage engineering. Laryngoscope. 2018; 128(7):E251-E257.

[13] RASHEED T, BILAL M, ZHAO Y, et al. Physiochemical characteristics and bone/cartilage tissue engineering potentialities of protein-based macromolecules- A review. Int J Biol Macromol. 2019;121:13-22.

[14] YAMASAKI A, KUNITOMI Y, MURATA D, et al. Osteochondral regeneration using constructs of mesenchymal stem cells made by bio three-dimensional printing in mini-pigs. J Orthop Res. 2019;37(6): 1398-1408.

[15] PAUL A, MANOHARAN V, KRAFFT D, et al. Nanoengineered biomimetic hydrogels for guiding human stem cell osteogenesis in three dimensional microenvironments. J Mater Chem B. 2016;4(20):3544-3554.

[16] ROSETI L, VCAVALLO C, DESANDO G, et al. Three-Dimensional Bioprinting of Cartilage by the Use of Stem Cells: A Strategy to Improve Regeneration. Materials (Basel). 2018;11(9):1749.

[17] CHEN CK, HUANG SC. Preparation of reductant-responsive N-maleoyl- functional chitosan/poly(vinyl alcohol) nanofibers for drug delivery. Mol Pharm. 2016;13(12):4152-4167.

[18] ANDERSON DE, BRIAN JOHNSTONE B. Dynamic Mechanical Compression of Chondrocytes for Tissue engineering: A Critical Review. Front Bioeng Biotechnol. 2017;5(76):1-20.

[19] PIZZOLATTI ALA, GAUDIG F, SEITZ D, et al. Glucosamine Hydrochloride and N-Acetylglucosamine Influence the Response of Bovine Chondrocytes to TGF-β3 and IGF in Monolayer and Three-Dimensional Tissue Culture. Tissue Eng Regen Med. 2018;15(6):781-791.

[20] SINGH BN, PANDA NN, MUND R, et al. Carboxymethyl cellulose enables silk fibroin nanofibrous scaffold with enhanced biomimetic potential for bone tissue engineering application. Carbohydr Polym. 2016;20(151):335-347.

[21] LEVINGSTONE TJ, THOMPSON E, MATSIKO A, et al. Multi-layeredcol-lagen-basedscaffoldsforosteochondraldefectrepairinrabbits. Acta Biomater. 2016;11(32):149-160.

[22] YUCEKUL A, OZDIL D, KUTLU NH, et al. Tri-layered composite plug for the repair of osteochondral defects: in vivo study in sheep. J Tissue Eng. 2017;13(8):2041731417697500.

[23] KARADJIAN M, ESSERS C, TSITLAKIDIS S, et al. Biological Properties of Calcium Phosphate Bioactive Glass Composite Bone Substitutes:Current Experimental Evidence. Int J Mol Sci. 2019;20(2):305.

[24] PRINCZ S, WENZEL U, TRITSCHLER H, et al. Automated bioreactor system for cartilage tissue engineering of human primary nasal septal chondrocytes. Biotechnol Technol(Berl). 2017;62(5):481-486.

[25] CURL WW, KROME J, GORDON ES, et al. Cartilage injuries: A review of 31, 516 knee arthroscopies. Arthroscopy. 1997;13(4):456-460.

[26] 袁清献,高丽兰,李瑞欣,等.3D打印丝素蛋白-Ⅱ型胶原软骨支架[J].山东大学学报(理学版),2018,53(3):82-87.

[27] LIAO JF, QU Y, CHU BY, et al. Biodegradable CSMA/PECA/graphene porous hybrid scaffold for cartilage tissue engineering. Sci Rep. 2015; 11(5):9879.

[28] Jin R, Teixeira LSM, Dijkstra PJ, et al. Injectable chitosan-based hydrogels for cartilage tissue engineering. Biomaterials. 2009;30(13): 2544-2551.

[29] CHANASAKULNIYOM M, GLIDLE A, COOPER JM. Cell proliferation and migration inside single cell arrays. Lab Chip. 2015;15(1):208-215.

[30] LORIES RJ, LUYTEN FP. The bone–cartilage unit in osteoarthritis. Nat Rev Rheumatol. 2011;7(1):43.

[31] FOSS C, MERZARI E, MIGLIARESI C, et al. Silk fibroin/hyaluronic acid 3D matrices for cartilage tissue engineering. Biomacromolecules. 2012; 14(1):38-47.

[32] ALIRAMAJI S, ZAMANIAN A, MOZAFARI M. Super-paramagnetic responsive silk fibroin/chitosan/magnetite scaffolds with tunable pore structures for bone tissue engineering applications. Mater Sci Eng C Mater Biol Appl. 2017;1(70):736-744.

[33] Li DW, Lei X, He FL, et al. Silk fibroin/chitosan scaffold with tunable properties and low inflammatory response assists the differentiation of bone marrow mesenchymal stem cells. Int J Biol Macromol. 2017; 105(Pt 1):584-597.

|