Chinese Journal of Tissue Engineering Research ›› 2016, Vol. 20 ›› Issue (31): 4658-4664.doi: 10.3969/j.issn.2095-4344.2016.31.014

Previous Articles Next Articles

Biomechanical analysis of dynamic simulation of three dimensional finite element models of knee joint meniscus

Chen Wen-dong1, Yang Guang2

- 1Department of Anesthesiology, First Affiliated Hospital of Kunming Medical University, Kunming 650032, Yunnan Province, China; 2Department of Orthopedics, Changzhou Fourth People’s Hospital, Changzhou 213001, Jiangsu Province, China

-

Revised:2016-05-10Online:2016-07-22Published:2016-07-22 -

Contact:Chen Wen-dong, M.D., Attending physician, Department of Anesthesiology, First Affiliated Hospital of Kunming Medical University, Kunming 650032, Yunnan Province, China -

About author:Chen Wen-dong, M.D., Attending physician, Department of Anesthesiology, First Affiliated Hospital of Kunming Medical University, Kunming 650032, Yunnan Province, China -

Supported by:the Applied Basic Research Project of Changzhou Municipal Science and Technology Bureau, No. CJ20130049

CLC Number:

Cite this article

Chen Wen-dong, Yang Guang. Biomechanical analysis of dynamic simulation of three dimensional finite element models of knee joint meniscus[J]. Chinese Journal of Tissue Engineering Research, 2016, 20(31): 4658-4664.

share this article

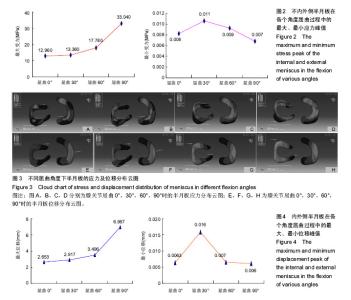

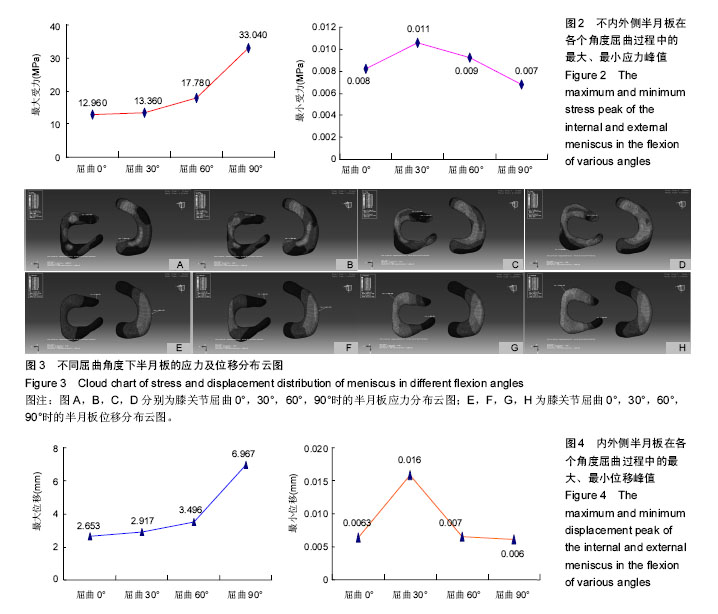

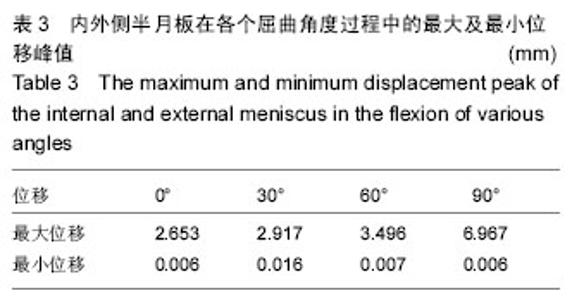

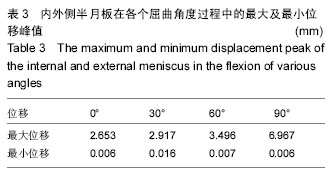

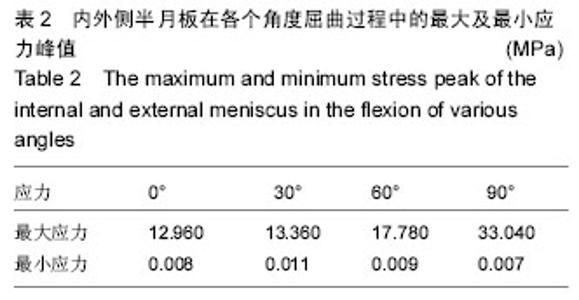

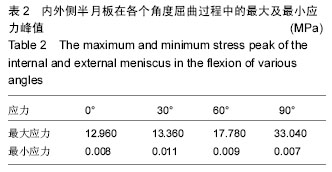

2.1 模型的验证 通过获取正常成人膝关节MRI二维图像,利用医学有限元仿真软件Mimics 10.01、逆向工程软件Rapidform XOR3及Abaqus 6.10-1高级有限元分析软件建立的动态仿真有限元模型进行验证,本研究动态仿真模拟在股骨方向施加载荷垂直大小为300 N的力后,膝关节从0°-90°屈曲过程生物力学分析得出的应力结果与位移结果与Filardi[12]和Mologne等[13]的研究结果相似,验证该模型有效。 2.2 膝关节三维有限元模型内外侧半月板在各个角度应力分布 正常膝关节屈曲0°,30°,60°,90°时,其承受垂直向下的300 N力后,屈曲0°-90°的最大应力点从内侧半月板后角胫骨附着面前缘移动到外侧半月板前角胫骨附着面后缘,其大小从12.96 MPa缓慢增加到33.04 MPa;最小应力点从外侧半月板前角股骨面后上缘移动到外侧半月板后角后上缘,其大小从0.008 21 MPa缓慢变化到0.006 79 MPa,见表2及图2。从应力分布云图上看,随着角度的增加外侧半月板中间靠近前角的范围应力越来越大,内侧半月板中间的部分应力范围也慢慢变大,且外侧半月板应力范围大于内侧半月板,见图3。"

| [1] 裴国献,张元智,主编.数字骨科学[M].北京:人民卫生出版社,2009:502-503. [2] 王洪伟,王晓红.有限元分析法在脊柱骨折研究中的应用进展[J].中华创伤杂志,2012,28(6):1074-1076. [3] 赵凡,刘正,王炳强,等.有限元模拟单节段腰椎小关节分级切除对腰椎稳定性的影响[J].中华医学杂志,2015,95(13): 973-977. [4] 黄振宇,董跃福.基于有限元方法的正常和早期OA膝关节生物力学行为比较[J].中国数字医学,2015,(5):6-9. [5] 中国解剖学会体质调查委员会编.中国人解剖数值[M].北京:人民卫生出版社,2002:27. [6] Moyer RF, Ratneswaran A, Beier F, et al.Osteoarthritis year in review 2014: mechanics--basic and clinical studies in osteoarthritis.Osteoarthritis Cartilage. 2014; 22(12):1989-2002. [7] Donahue TL, Fisher MB, Maher SA. Meniscus mechanics and mechanobiology.J Biomech. 2015; 48(8):1341-1342. [8] Duchman KR, DeVries NA, McCarthy MA, et al. Biomechanical evaluation of medial patellofemoral ligament reconstruction.Iowa Orthop J. 2013; 33:64-69. [9] Hopper GP, Leach WJ, Rooney BP, et al. Does degree of trochlear dysplasia and position of femoral tunnel influence outcome after medial patellofemoral ligament reconstruction? Am J Sports Med. 2014; 42(3):716-722. [10] DeVries Watson NA, Duchman KR, et al. A Finite Element Analysis of Medial Patellofemoral Ligament Reconstruction.Iowa Orthop J. 2015; 35:13-19. [11] Stephen JM, Kittl C, Williams A, et al. Effect of Medial Patellofemoral Ligament Reconstruction Method on Patellofemoral Contact Pressures and Kinematics.Am J Sports Med. 2016; 44(5):1186-1194. [12] Filardi V. Stress shielding in the bony chain of leg in presence of varus or valgus knee.J Orthop. 2015; 12(2): 102-110. [13] Mologne TS, Cory E, Hansen BC, et al. Osteochondral allograft transplant to the medial femoral condyle using a medial or lateral femoral condyle allograft: is there a difference in graft sources? Am J Sports Med. 2014; 42(9):2205-2213. [14] Laprade RF, Wijdicks CA.Surgical technique: development of an anatomic medial knee reconstruction. Clin Orthop Relat Res. 2012; 470(3): 806-814. [15] Steinbrück A, Woiczinski M, Weber P, et al. Posterior cruciate ligament balancing in total knee arthroplasty: a numerical study with a dynamic force controlled knee model.Biomed Eng Online. 2014; 13:91. [16] Barrow AE, Pilia M, Guda T, et al. Femoral suspension devices for anterior cruciate ligament reconstruction: do adjustable loops lengthen? Am J Sports Med. 2014; 42(2):343-349. [17] Deo S, Getgood A. A Technique of Superficial Medial Collateral Ligament Reconstruction Using an Adjustable-Loop Suspensory Fixation Device.Arthrosc Tech. 2015; 4(3):e261-265. [18] Born TR, Biercevicz AM, Koruprolu SC, et al. Biomechanical and Computed Tomography Analysis of Adjustable Femoral Cortical Fixation Devices for Anterior Cruciate Ligament Reconstruction in a Cadaveric Human Knee Model.Arthroscopy. 2016; 32(2):253-261. [19] Toutoungi DE,Lu Tw,Leardini A,et al.Cruciate ligament forces in the knee during rehabilitation exercise.Clin Biomech. 2000;15(3):176-187. [20] Zheng N,Fleisig GS,Escamilla RF,et a1.An analytical model of the knee for estimation of internal forces duringexercise.J Biomech. 1998;31:963-967. [21] Huss RA,Holstein H,O,Connor JJ. A mathematical model of forces in the knee under isometric quadriceps contractions. Clin Biomech. 2000;15:112-122. [22] Wongchaisuwat C, Hemami H,Bucher HJ.Control of sliding and rolling at natural joints. J Biomech Eng. 1984;106(4):368-375. [23] Engin AE,Turner ST. An innovative approach to the solution of highly nonlinear dynamics problems associated with joint biomechanics.Proceedings of the 1991 Biomechanics Symposium,Ohio State University, Columbus,OH,1991:225. [24] Engin AE,Turner ST.Improved dynamics model of the human knee joint and its response to impact loading on the lower leg. J Biomech Eng,1993;115(2):137-143. [25] Catalfamo PF, Aguiar G, Curi J, Braidot A. Anterior Cruciate Ligament Injury: Compensation during Gait using Hamstring Muscle Activity.Open Biomed Eng J. 2010; 4:99-106. [26] Kazemi M, Dabiri Y, Li LP. Recent advances in computational mechanics of the human knee joint.Comput Math Methods Med. 2013; 2013:718423. [27] Erdemir A. Open Knee: A Pathway to Community Driven Modeling and Simulation in Joint Biomechanics.J Med Device. 2013; 7(4):0409101-409101. [28] Opar DA, Williams MD, Timmins RG, et al. Knee flexor strength and bicep femoris electromyographical activity is lower in previously strained hamstrings.J Electromyogr Kinesiol. 2013; 23(3):696-703. [29] Opar DA, Serpell BG. Is there a potential relationship between prior hamstring strain injury and increased risk for future anterior cruciate ligament injury?Arch Phys Med Rehabil. 2014; 95(2):401-405. [30] Meng Q, Jin Z, Wilcox R, et al. Computational investigation of the time-dependent contact behaviour of the human tibiofemoral joint under body weight.Proc Inst Mech Eng H. 2014; 228(11):1193-1207. [31] González-Carbonell RA, Ortiz-Prado A, Jacobo-Armendáriz VH, et al. 3 D patient-specific model of the tibia from CT for orthopedic use.J Orthop. 2015; 12(1):11-16. [32] Baldwin MA, Clary CW, Fitzpatrick CK, et al. Dynamic finite element knee simulation for evaluation of knee replacement mechanics.J Biomech. 2012;45(3): 474-483. [33] Fitzpatrick CK, Komistek RD, Rullkoetter PJ. Developing simulations to reproduce in vivo fluoroscopy kinematics in total knee replacement patients.J Biomech. 2014; 47(10):2398-2405. [34] Fitzpatrick CK, Rullkoetter PJ. Estimating total knee replacement joint load ratios from kinematics.J Biomech. 2014; 47(12):3003-3011. [35] Pianigiani S, Vander Sloten J, Pascale W, et al. A new graphical method to display data sets representing biomechanical knee behaviour. J Exp Orthop. 2015; 2(1):18. [36] Nenezic D, Kocijancic I .The value of the sagittal-oblique MRI technique for injuries of the anterior cruciate ligament in the knee.Radiol Oncol. 2013; 47(1):19-25. [37] Muhle C, Ahn JM, Dieke C. Diagnosis of ACL and meniscal injuries: MR imaging of knee flexion versus extension compared to arthroscopy. Springerplus. 2013; 2(1):213. [38] Kosaka M, Nakase J, Toratani T, et al. Oblique coronal and oblique sagittal MRI for diagnosis of anterior cruciate ligament tears and evaluation of anterior cruciate ligament remnant tissue.Knee. 2014; 21(1): 54-57. [39] Taketomi S, Inui H, Sanada T, et al. Remnant-preserving anterior cruciate ligament reconstruction using a three-dimensional fluoroscopic navigation system.Knee Surg Relat Res. 2014;26(3): 168-176. [40] Araki D, Kuroda R, Matsumoto T, et al. Three-dimensional analysis of bone tunnel changes after anatomic double-bundle anterior cruciate ligament reconstruction using multidetector-row computed tomography.Am J Sports Med. 2014; 42(9): 2234-2241. |

| [1] | Huang Dengcheng, Wang Zhike, Cao Xuewei. Comparison of the short-term efficacy of extracorporeal shock wave therapy for middle-aged and elderly knee osteoarthritis: a meta-analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1471-1476. |

| [2] | Xu Feng, Kang Hui, Wei Tanjun, Xi Jintao. Biomechanical analysis of different fixation methods of pedicle screws for thoracolumbar fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1313-1317. |

| [3] | Zhang Tongtong, Wang Zhonghua, Wen Jie, Song Yuxin, Liu Lin. Application of three-dimensional printing model in surgical resection and reconstruction of cervical tumor [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1335-1339. |

| [4] | Chen Xinmin, Li Wenbiao, Xiong Kaikai, Xiong Xiaoyan, Zheng Liqin, Li Musheng, Zheng Yongze, Lin Ziling. Type A3.3 femoral intertrochanteric fracture with augmented proximal femoral nail anti-rotation in the elderly: finite element analysis of the optimal amount of bone cement [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1404-1409. |

| [5] | Zhou Jihui, Li Xinzhi, Zhou You, Huang Wei, Chen Wenyao. Multiple problems in the selection of implants for patellar fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1440-1445. |

| [6] | Zeng Yanhua, Hao Yanlei. In vitro culture and purification of Schwann cells: a systematic review [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(7): 1135-1141. |

| [7] | Song Chengjie, Chang Hengrui, Shi Mingxin, Meng Xianzhong. Research progress in biomechanical stability of lateral lumbar interbody fusion [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 923-928. |

| [8] | Liu Zhao, Xu Xilin, Shen Yiwei, Zhang Xiaofeng, Lü Hang, Zhao Jun, Wang Zhengchun, Liu Xuzhuo, Wang Haitao. Guiding role and prospect of staging and classification combined collapse prediction method for osteonecrosis of femoral head [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 929-934. |

| [9] | Kong Lingbao, Lü Xin. Effect of implant selection and approach on support in the operation of posterolateral tibial plateau fractures [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 942-947. |

| [10] | Huang Dengcheng, Wang Zhike, Cao Xuewei. Intravenous, topical tranexamic acid alone or their combination in total knee arthroplasty: a meta-analysis of randomized controlled trials [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 948-956. |

| [11] | He Xiangzhong, Chen Haiyun, Liu Jun, Lü Yang, Pan Jianke, Yang Wenbin, He Jingwen, Huang Junhan. Platelet-rich plasma combined with microfracture versus microfracture in the treatment of knee cartilage lesions: a meta-analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 964-969. |

| [12] | Zhong Hehe, Sun Pengpeng, Sang Peng, Wu Shuhong, Liu Yi. Evaluation of knee stability after simulated reconstruction of the core ligament of the posterolateral complex [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 821-825. |

| [13] | Xu Yulin, Shen Shi, Zhuo Naiqiang, Yang Huilin, Yang Chao, Li Yang, Zhao Heng, Zhao Lu. Biomechanical comparison of three different plate fixation methods for acetabular posterior column fractures in standing and sitting positions [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 826-830. |

| [14] | Cai Qunbin, Zou Xia, Hu Jiantao, Chen Xinmin, Zheng Liqin, Huang Peizhen, Lin Ziling, Jiang Ziwei. Relationship between tip-apex distance and stability of intertrochanteric femoral fractures with proximal femoral anti-rotation nail: a finite element analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 831-836. |

| [15] | Liu Shaohua, Zhou Guanming, Chen Xicong, Xiao Keming, Cai Jian, Liu Xiaofang. Influence of anterior cruciate ligament defect on the mid-term outcome of fixed-bearing unicompartmental knee arthroplasty [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 860-865. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||