[1] 黄政基,姚霁航,张晓猛,等.桡骨远端骨折不同治疗方法的研究进展[J].中国老年学杂志, 2018,38(9):249-251.

[2] 李佳,刘勃,董天华,等. 2010-2011年西南地区11所医院60岁以上尺桡骨远端骨折患者流行病学分析[J].中华老年骨科与康复电子杂志,2017,3(4):244-247.

[3] 姜昆,陶宝琛,魏成建.小夹板治疗桡骨远端关节内骨折的有限元分析[J].医用生物力学,2018,33(3):206-211.

[4] 倪鹏辉,张鹰,杨晶,等.临床骨科中应用的有限元分析法:新理论与新进展[J].中国组织工程研究,2016,20(31):4693-4699.

[5] 杨雨润,徐小东,陈瀛,等.桡骨头骨折与伴发损伤的关系及治疗方式的研究[J].中华创伤骨科杂志, 2016, 18(7):602-606.

[6] 张子清,郭淑女,古汉南,等.桡骨头三维有限元模型建立及生物力学分析[J].中国医学创新,2017,14(13):30-33.

[7] HUA Z, WANG JW, LU ZF, et al. The biomechanical analysis of three-dimensional distal radius fracture model with different fixed splints. Technol Health Care.2018;26(8):1-13.

[8] EBINGER T, KOEHLER DM, DOLAN LA, et al. Obesity increases complexity of distal radius fracture in fall from standing height. J Orthop Trauma. 2016;30(8):450-455.

[9] 周建华,王跃.有限元分析在骨科中的应用及研究进展[J].实用医院临床杂志, 2018,15(1):205-208.

[10] 吴晗,张鉴,李强,等.手术治疗老年人不稳定性桡骨远端骨折的疗效[J].中国老年学杂志,2016,36(12):3004-3005.

[11] BAUMBACH SF, BINDER J, SYNEK A, et al. Analysis of the three-dimensional anatomical variance of the distal radius using 3D shape models. Bmc Med Imaging. 2017;17(1):23.

[12] BOOZ C, NÖSKE J, ALBRECHT MH, et al. Traumatic bone marrow edema of the calcaneus: Evaluation of color-coded virtual non-calcium dual-energy CT in a multi-reader diagnostic accuracy study. Eur J Radiol. 2019;118(1): 207-214.

[13] 孙文涛,李鹏飞,林梓凌,等.基于断裂力学模拟3种不同跌倒状态下股骨近端骨折的有限元分析[J].新疆医科大学学报,2017,40 (40):1529-1532.

[14] JILKA RL, O’BRIEN CA. The role of osteocytes in age-related bone loss. Curr Osteoporos Rep. 2016;14(1):16-25.

[15] SYNEK A, CHEVALIER Y, BAUMBACH SF, et al. The influence of bone density and anisotropy in finite element models of distal radius fracture osteosynthesis: Evaluations and comparison to experiments. J Biomech. 2015;48(15): 4116-4123.

[16] 魏成建,陶宝琛,张满臣,等.动力气囊压垫纠正桡骨远端AO C3.1型骨折残余侧方移位的三维有限元分析[J].医用生物力学,2018, 33(1):13-17.

[17] 刘志东,穆洪鑫.保留旋前方肌对桡骨远端骨折掌侧钢板内固定术后疗效及腕关节功能影响[J].当代医学,2018,24(36): 139-141.

[18] 王跃进,于云辉,翟澍龙,等.利用致伤机理分析鉴定损伤形成过程2例[J].中国法医学杂志,2016,31(2):226-228.

[19] 纪方,王光超.桡骨远端骨折及其周围结构损伤的处理[J].国际骨科学杂志,2017,38(4):209-212.

[20] 申琳,曾宪铁.桡骨远端骨折的分型及治疗进展[J].中国中西医结合外科杂志,2017,23(3):330-333.

[21] 王古衡,谢仁国,潘张军,等.不同桡骨远端骨折分型方法中骨折类型与预后功能的关系分析[J].中华创伤骨科杂志,2016,18(1): 74-78.

[22] 陈妍妤,应祖光,朱振康,等.股骨纵向受压时的应力分布特征分析[J].固体力学学报,2016,37(1):73-78.

[23] WENTZELL S, NESBITT RS, MACIONE J, et al. Measurement of lacunar bone strains and crack formation during tensile loading by digital volume correlation of second harmonic generation images. J Mech Behav Biomed Mater. 2016; 60(5):148-156.

[24] 郑利钦,林梓凌,李鹏飞,等.动态载荷下松质骨对骨质疏松性股骨颈骨折断裂力学影响的有限元分析[J].中国组织工程研究,2019, 23(12):89-94.

[25] KOČIŠ J, KELBL M, VESELÝ R, et al. Management of odontoid fractures with compression screw and anterior transarticular screw fixation in elderly patients. Acta Chir Orthop Traumatol Cech. 2017;84(1):35-39.

[26] 明新杰,明立功,明新忠,等.功能性外固定器治疗桡骨远端骨折的生物力学测试及临床研究[J].中国骨与关节损伤杂志,2004, 19(2):107-109.

[27] SALAS C, BRANTLEY JA, CLARK J, et al. Damage in a distal radius fracture model treated with locked volar plating after simulated postoperative loading. J Hand Surg Am. 2018; 43(7):679-679.

[28] 丁勇,杨利,祝丰奎,等.掌屈前臂旋后位夹板固定治疗老年掌侧Barton骨折[J].中医药学报,2016,44(4):117-119.

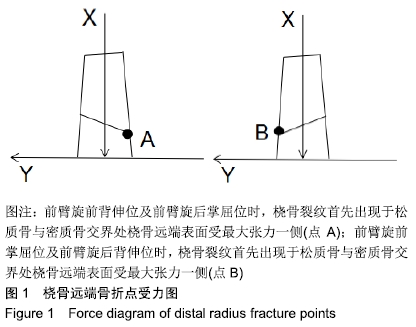

[29] 张朝驹,何川,陈洪卫,等.李孝林.基于有限元模型分析伸直型桡骨远端骨折的生物力学特点[J].中国组织工程研究,2019,23(12): 1898-1902.

[30] 王明鑫,尹望平,曾庆敏,等.尺骨短缩截骨术治疗桡骨远端骨折畸形愈合的生物力学研究[J].中华手外科杂志,2017,33(3): 205-208.

|