[1] BAE EB, KIM SJ, CHOI JW, et al.A Clinical Retrospective Study of Distal Extension Removable Partial Denture with Implant Surveyed Bridge or Stud Type Attachment.Biomed Res Int.2017;2017(2):1-7.

[2] EOM JW, LIM YJ, KIM MJ, et al.Three-dimensional finite element analysis of implant-assisted removable partial dentures.J Prosthet Dent.2017;117(6):735-742.

[3] DE PAULA GA, SILVA GC, VILAÇA ÊL, et al.Biomechanical behavior of tooth-implant supported prostheses with different implant connections.Implant Dent.2018;27(3):294-302.

[4] TAKAYAMA Y, SASAKI H, GOTO M, et al.Morphological factors of mandibular edentulous alveolar ridges influencing the movement of dentures calculated using finite element analysis. J Prosthod Res.2011;55(2):98-103.

[5] PAPAVASILIOU G.Three-dimensional finite element analysis of stress- distribution around single tooth implants as a function of bony support, prosthesis type,and loading during function.J Prosthet Dent.1996;76(6):633-640.

[6] RUBIN C, KRISHNAMURTHY N, CAPILOUTO EY, et al.Stress analysis of the human tooth using 3D finite element model.J Dent Res.1983;62(2):82-86.

[7] MEMARI Y, GERAMY A, FAYAZ A, et al.Influence of Implant Position on Stress Distribution in Implant-Assisted Distal Extension Removable Partial Dentures: A 3D Finite Element Analysis.J Dent.2014;11(5):523-530.

[8] ORTIZ-PUIGPELAT O, LÁZARO-ABDULKARIM A, DE MEDRANO-REÑÉ JM, et al.Influence of Implant Position in Implant-Assisted Removable Partial Denture: A Three-Dimensional Finite Element Analysis.J Prosthodont. 2019;28(2):e675-e681.

[9] BARONE S, PAOLI A, RAZIONALE AV, et al.Computer aided modelling to simulate the biomechanical behaviour of customised orthodontic removable appliances.Int J Interacti Des Manufact.2016;10(4):387-400.

[10] SHAHMIRI R, DAS R.Finite element analysis of implant-assisted removable partial dentures: Framework design considerations.J Prosthet Dent.2017;118(2):177-186.

[11] 王洪宁,秦行林,刘东旭,等.基于micro-CT成像的仿真牙周膜有限元建模探讨[J].口腔疾病防治,2016,24(5):283-287.

[12] LEE KS, SHIN JH, KIM JE, et al.Biomechanical evaluation of a tooth restored with high performance polymer PEKK Post-Core System: A 3D finite element analysis. Biomed Res Int.2017;2017(2):1373127.

[13] 江鹭鹭,蔺增,邓春富,等.不同冠根比平台转换结构种植义齿应力分布三维有限元分析[J].中国实用口腔科杂志, 2016,9(5): 300-303.

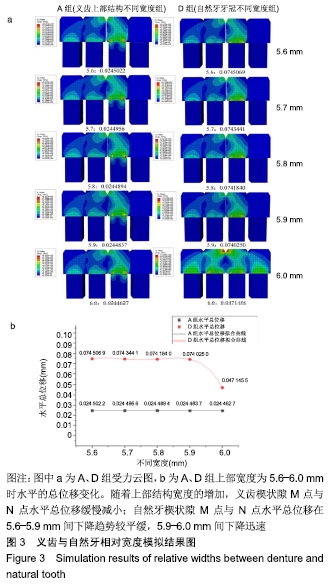

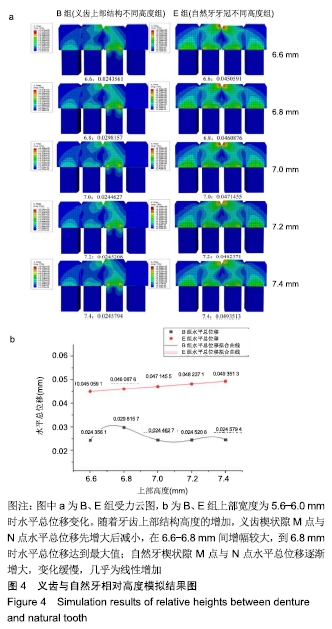

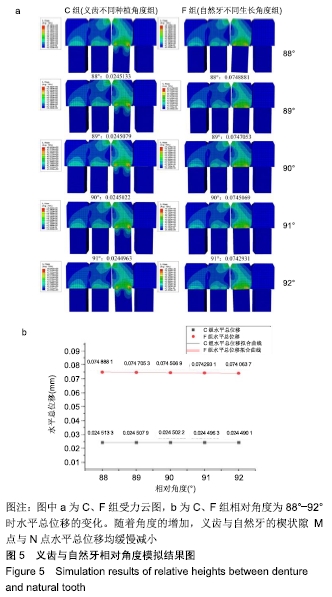

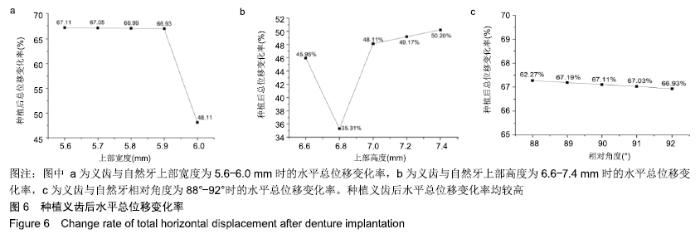

[14] 张站柱,杨德圣,乔爱科.种植义齿相对高度对塞牙影响的有限元分析[J].北京生物医学工程,2012,31(6):556-559.

[15] CATTANEO PM, DALSTRA M, MELSEN B.The Finite Element Method: a Tool to Study Orthodontic Tooth Movement.J Dent Res.2005;84(5):428-433.

[16] CHEN G, FAN W, MISHRA S, et al.Tooth fracture risk analysis based on a new finite element dental structure models using micro-CT data.Comput Biol Med.2012;42(10):957-963.

[17] 卢红飞,麦志辉,陈奇,等.不同加载方式压低上前牙时初始应力在牙体、牙周膜及牙槽骨分布的三维有限元分析[J].中国组织工程研究,2011,15(48):8964-8967.

[18] 黄楠楠.不同磨牙关系下颌第一磨牙咬合接触类型分析及有限元受力研究[D].重庆:重庆医科大学,2014.

[19] OLADAPO BI, ABOLFAZL ZAHEDI S, VAHIDNIA F, et al. Three-dimensional finite element analysis of a porcelain crowned tooth.Beni-Suef Univ J Basic Appl Sci. 2018;7(4): 461-464.

[20] 王野平,林小英,周慧峰.Mimics和Geomagic辅助下建立固定义齿的有限元模型[J].医用生物力学,2010,25(6):433-438.

[21] 卢红飞,艾虹,麦志辉,等.牙齿牙周矫治装置三合一三维有限元模型的建立[J].中国组织工程研究,2010,14(22):4010-4013.

[22] 吕纯洁,董湘怀,潘卫红.上颌第二磨牙的三维有限元模型及受力分析[J].临床口腔医学杂志,2005,21(4):209-211.

[23] 罗云,任杰.临床食物嵌塞病症的常见病因分析及序列治疗[J].国际口腔医学杂志,2016,43(1):1-4.

[24] BIDRA AVINASH S.Nonsurgical management of inflammatory periimplant disease caused by food impaction: A Clinical Report.J Prosthet Dent.2014;111(2):96-100.

[25] KAWAMURA J, TAMAYA N.A finite element analysis of the effects of archwire size on orthodontic tooth movement in extraction space closure with miniscrew sliding mechanics. Prog Orthod.2019;20(1):3.

|