Chinese Journal of Tissue Engineering Research ›› 2024, Vol. 28 ›› Issue (21): 3326-3333.doi: 10.12307/2024.093

Previous Articles Next Articles

Structural design of tibial intramedullary stem of artificial knee joint

Cao Xuekun1, Dong Wanpeng1, Dong Yuefu2, Zhang Zhen1, Zhang Jichao1, Li Jiayi1, Su Dejun1, Ma Honghao1

- 1School of Materials Science and Engineering, Shanghai University of Engineering Science, Shanghai 201620, China; 2Lianyungang Hospital Affiliated to Xuzhou Medical University, Lianyungang 222061, Jiangsu Province, China

-

Received:2023-04-20Accepted:2023-06-28Online:2024-07-28Published:2023-09-27 -

Contact:Dong Wanpeng, PhD, Associate professor, School of Materials Science and Engineering, Shanghai University of Engineering Science, Shanghai 201620, China -

About author:Cao Xuekun, Master candidate, School of Materials Science and Engineering, Shanghai University of Engineering Science, Shanghai 201620, China -

Supported by:National Natural Science Foundation of China, No. 31670956 (to DYF)

CLC Number:

Cite this article

Cao Xuekun, Dong Wanpeng, Dong Yuefu, Zhang Zhen, Zhang Jichao, Li Jiayi, Su Dejun, Ma Honghao. Structural design of tibial intramedullary stem of artificial knee joint[J]. Chinese Journal of Tissue Engineering Research, 2024, 28(21): 3326-3333.

share this article

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

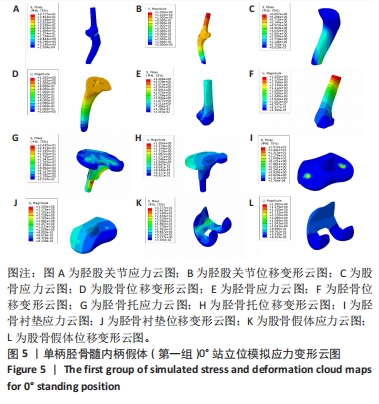

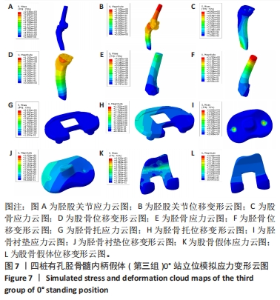

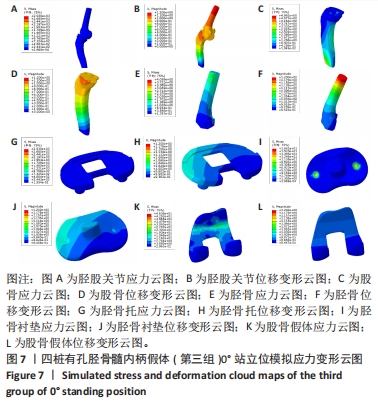

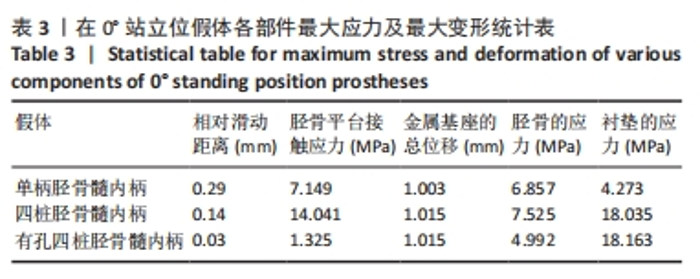

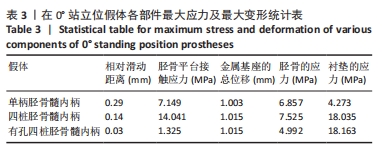

由图5-7中可以看出,在接触压力、接触总应力和骨的Mises应力分布上,主要由股骨假体承受了较多的负荷,其中,单柄胫骨髓内柄中,股骨假体占比为49.3%;四桩胫骨髓内柄假体中,股骨假体占比为33.5%;有孔四桩胫骨髓内柄假体中,股骨假体占比为61.9%。另外胫骨衬垫和胫骨托也承受了一定程度的负荷。在压力负荷下接触面之间的相对滑动是很小的,最大值为0.29 mm。相对滑动距离与文献中的接触滑动距离0.004 mm相差略大[4],这可能与力的加载位置有关。骨的Mises应力主要分布在胫骨中部,在单柄胫骨髓内柄颈部以及其他胫骨平台和股骨假体中上部也有一定的应力分布。 图5-7反映了假体总体及各组件站立位时应力及变形量分布云图,其统计结果如表3。由此得出结论:对于单柄胫骨髓内柄假体,最大应力出现在单柄假体颈部与平台连接处,位移主要集中在平台左后部;四桩胫骨髓内柄假体和有孔四桩胫骨髓内柄假体应力分布较均匀,无明显的应力集中现象;股骨假体最大应力出现在股骨假体中上部区域,此处受到一定弯矩,故应力较大;衬垫因上表面受力较大故应力和变形均较大。金属基座的总位移分别为1.003,1.015和1.015 mm,与未安装到骨骼的胫骨平台假体的位移值0.003 872 24 mm相差略大[19],这主要是由于骨骼的位移造成的。"

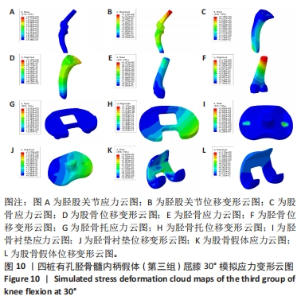

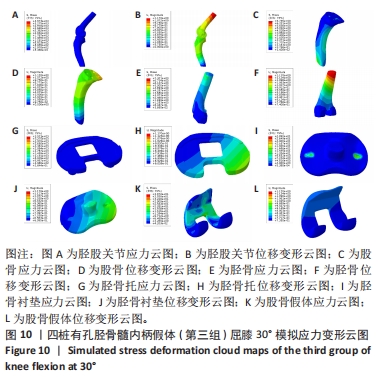

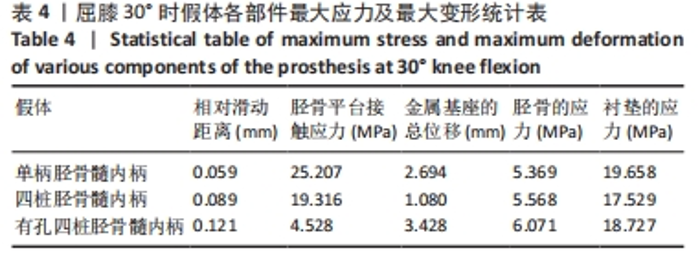

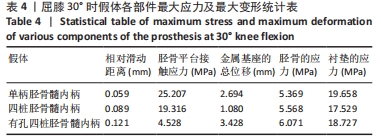

由图8-10中可以看出,在接触压力、接触总应力和骨的Mises应力分布上,对于单柄胫骨髓内柄假体组,胫骨托承担了大部分的负荷,占比为38%,其应力集中现象也较明显,位移主要发生在胫骨托左前部;对于四桩胫骨髓内柄假体组和有孔四桩胫骨髓内柄假体组,仍然是股骨假体承担了主要负荷,占比分别为33.8%和47%,胫骨假体所承担应力较少。骨的Mises应力主要分布在胫骨中部,在单柄胫骨髓内柄颈部以及其他胫骨平台和股骨假体中上部也有一定的应力分布。 图8-10反映了假体总体、各组件屈膝30°时应力及变形量分布云图,其统计结果如表4。由此可以得出:对于单柄胫骨髓内柄假体组,应力主要集中于胫骨平台和胫骨柄处;而四桩胫骨髓内柄假体组和有孔四桩胫骨髓内柄假体组应力分布均匀,无明显应力集中现象。股骨假体应力最大出现在中上部,此处受到一定的弯矩,故应力较大,且存在应力集中现象;衬垫的上表面受力较大故应力和变形均较大,但相比而言,四桩有孔胫骨髓内柄假体组的变形更小。金属基座的总位移分别为2.694、1.080和3.428 mm,与未安装到骨骼上的胫骨平台假体的位移值0.001 890 7 mm相差略大[19],这主要是由于骨骼的位移造成的。"

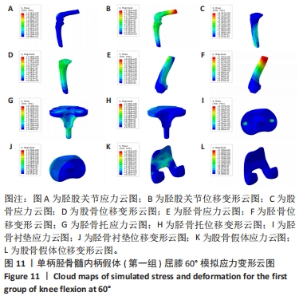

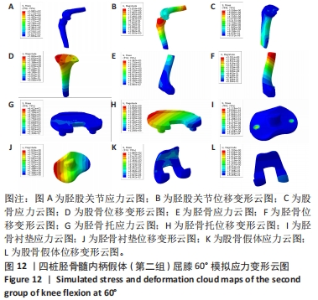

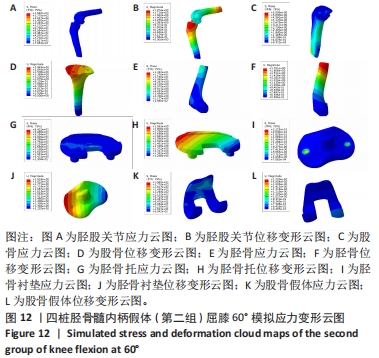

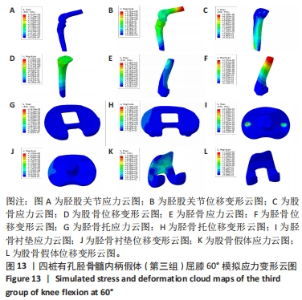

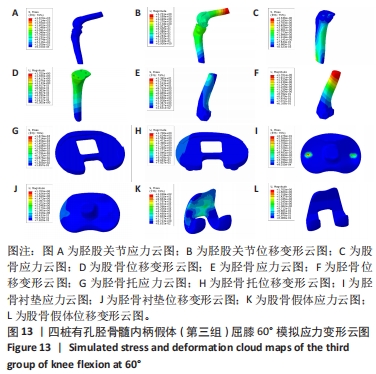

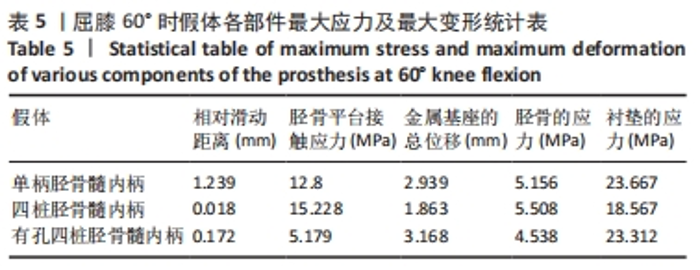

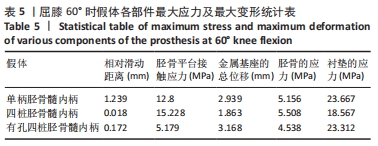

由图11-13中可以看出,在接触压力、接触总应力和骨的Mises应力分布上,对于单柄胫骨髓内柄组和四桩胫骨髓内柄组,胫骨衬垫承担了大部分的负荷,占比分别为39.7%和32%,不利于衬垫的长期磨损;对于有孔四桩胫骨髓内柄组,股骨假体承担了主要负荷,占比为70%。骨的Mises应力主要分布在胫骨中下部,在单柄胫骨髓内柄假体颈部以及其他胫骨平台和股骨假体中上部也有一定的应力分布。 图11-13反映了假体总体及各组件屈膝60°时应力及变形量分布云图,结果如表5。由此可以得出:单柄胫骨髓内柄假体组胫骨假体平台最大应力在胫骨柄两侧翼与平台连接处,所受应力较大;四桩胫骨髓内柄假体组和有孔四桩胫骨髓内柄假体组应力分布均匀,无应力集中现象;股骨假体最大应力仍是中上部区域,此处应力集中,并且受到一定的弯矩影响;衬垫因上表面受力,但受力较小,位移以四桩髓内柄假体组较大。金属基座的总位移为2.939,1.863和3.168 mm,与未安装到骨骼上的胫骨平台的位移值0.004 079 7 mm相差略大[19],这主要是由于骨骼的位移造成的。"

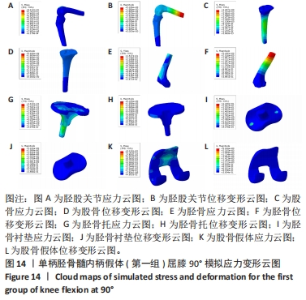

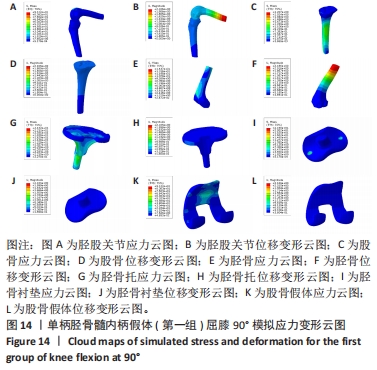

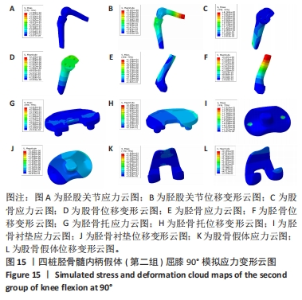

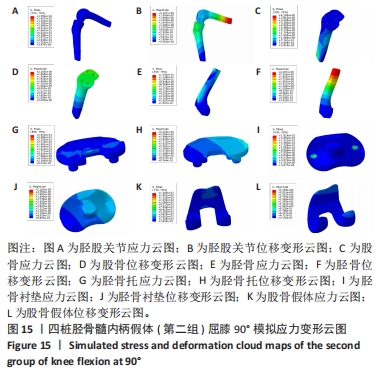

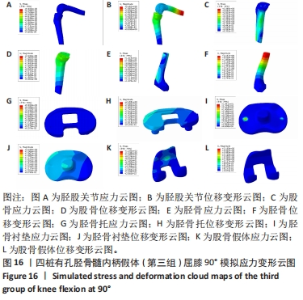

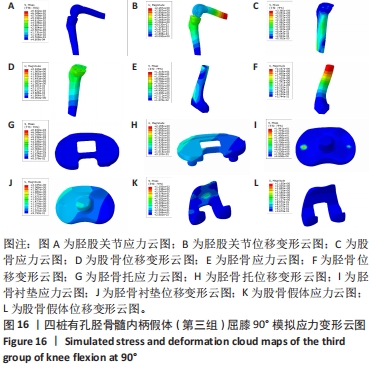

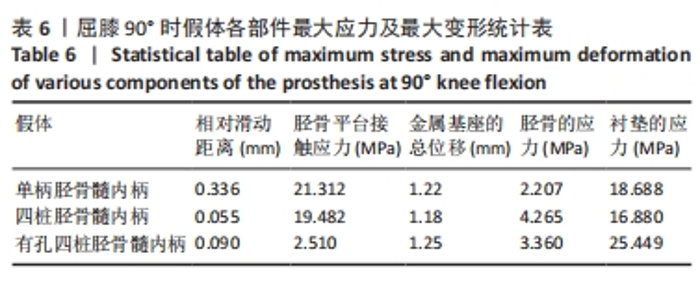

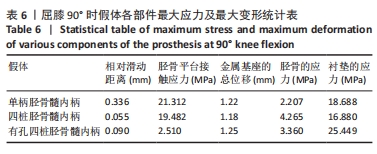

由图14-16中可以看出,在接触压力、接触总应力和骨的Mises应力分布上,股骨假体承担了主要负荷,占比分别为34.9%,68.5%和71.1%。骨的Mises应力主要分布在胫骨下部和股骨上部,胫骨平台也有一定的应力分布。 图14-16反映了假体总体及各组件屈膝90°时的最大应力及最大变形量,其统计结果如表6。由此可以得出:单柄胫骨髓内柄假体组胫骨假体最大应力出现在胫骨假体柄部侧翼与平台相连位置,有应力集中现象;四桩胫骨髓内柄假体组和有孔四桩胫骨髓内柄假体组胫骨假体部分应力分布均匀;股骨假体最大应力出现在中上部区域,主要受到一定的弯矩影响;衬垫所受应力集中于衬垫上表面,受力均匀,变形较小。金属基座的总位移分别为1.22,1.18和1.25 mm,与未安装到骨骼的胫骨平台假体位移值0.004 079 7 mm相差略大[19],这主要是由于骨骼位移造成的。 "

| [1] 李志.基于功能梯度材料胫骨假体的有限元分析[D].太原:太原理工大学,2021. [2] 马妮.个性化人工膝关节设计及其生物力学特性研究[D].北京:清华大学,2010. [3] 张吉超,董万鹏,董跃福.OA膝关节在TKA手术前后不同角度下的数值仿真研究[D].上海:上海工程技术大学,2022. [4] 张银光.以三维有限元方法分析设计可保留前后交叉韧带人工全膝关节假体[D].北京:中国人民解放军军医进修学院,2008. [5] CHONG DY, HANSEN UN, VAN DER VENNE R, et al. The influence of tibial component fixation techniques on resorption of supporting bone stock after total knee replacement. J Biomech. 2011;44(5): 948-954. [6] SCOTT CEH, BIANT LC. The role of the design of tibial components and stems in knee replacement. J Bone Joint Surg Br. 2012;94(8):1009-1015. [7] BOLLARS P, LUYCKX JP, INNOCENTI B, et al. Femoral component loosening in high-flexion total knee replacement an in vitro comparison of high-flexion versus conventional designs. J Bone Joint Surg Br. 2011;93B(10):1355-1361. [8] SHEN Y, LI X, FU X, et al. A 3D finite element model to investigate prosthetic interface stresses of different posterior tibial slope. Knee Surg Sport Tr A. 2015;23(11):3330-3336. [9] SERVICE BC, KANG W, TURNBULL N, et al. Influence of Femoral Component Design on Retrograde Femoral Nail Starting Point. J Orthop Trauma. 2015;29(10):e380-e384. [10] ZHANG M, ZHANG K, GONG H. Biomechanical Effects of Tibial Stems with Different Structures on Human Knee Joint after Total Knee Arthroplasty: A Finite Element Analysis. J Bionic Eng. 2021;19(1):197-208. [11] FANG CH, LUAN YC, WANG ZW, et al. Moderate External Rotation of Tibial Component Generates More Natural Kinematics Than Internal Rotation After Total Knee Arthroplasty. Front Bioeng Biotechnol. 2022;10:7. [12] FUA-NIZAN R, RANI AMA, DIN MY, et al. Preliminary Study of Stress Distribution on Modified Femoral Component of Knee Implant at Maximum Flexion Angle. Adv Mater Sci Eng. 2020:17-22. [13] 张震,董跃福,陈秋平,等.基于CT和MRI影像数据融合构建个体化OA膝关节三维解剖模型[J].中国骨与关节损伤杂志,2019,34(12):1241-1244. [14] 李凯,周建华,王跃,等.膝关节假体安装方式对股骨远端应力屏蔽的影响[J].机械, 2019,46(4):9-15. [15] TEO A, MISHRA A, PARK I, et al. Polymeric Biomaterials for Medical Implants & Devices. Acs Biomaterials. 2013;12(11):203-209. [16] 刘晓敏.膝关节后外侧结构三维有限元模型的建立及生物力学研究[D].长沙:中南大学, 2011. [17] 韦亚军.不同角度力线对位的人工膝关节假体接触压力有限元分析[D].成都:电子科技大学,2021. [18] 相昌鑫.不同偏移角度载荷下膝关节假体的接触压力有限元分析[D].太原:太原理工大学,2019. [19] 冯天天. 膝关节数字化骨形态学研究及假体设计[D].武汉:华中科技大学,2013. [20] GODEST A, BEAUGONIN M, HAUG E, et al. Simulation of a knee joint replacement during a gait cycle using explicit finite element analysis. J Biomech. 2002;35(2):267-275. [21] 姬林松.不同型号膝关节PS型假体匹配的三维动态有限元分析[D].昆明:昆明医科大学,2016. [22] 孙孟帅.非骨水泥型胫骨平台假体在人工全膝关节置换术治疗骨性关节炎中的临床应用研究[D].西安:中国人民解放军空军军医大学,2018. [23] QUILEZ MP, SERAL B, PEREZ MA. Biomechanical evaluation of tibial bone adaptation after revision total knee arthroplasty: A comparison of different implant systems. PLoS One. 2017; 12(9): e0184361. [24] 强硕.肥胖患者膝关节置换中胫骨延长杆对胫骨应力分布影响的有限元研究[D].郑州:郑州大学,2017. [25] 王晖,杨朝旭,孟凡涛.胫骨托盘的不同结构设计对胫骨应力分布的影响[J].中华老年骨科与康复电子杂志,2020,6(6):321-326. |

| [1] | Li Yongjie, Fu Shenyu, Xia Yuan, Zhang Dakuan, Liu Hongju. Correlation of knee extensor muscle strength and spatiotemporal gait parameters with peak knee flexion/adduction moment in female patients with knee osteoarthritis [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(9): 1354-1358. |

| [2] | Li Chaojie, Gulati•Maitirouzi, Aierxiding•Abulaiti, Zheng Hui, Tu Hudi. Finite element analysis of medial patellofemoral ligament reconstruction at different flexion angles [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(9): 1359-1364. |

| [3] | Bi Gengchao, Zhang Yanlong, Li Qiuyue, Hu Longwei, Zhang Yu. Knee joint mechanics and activation characteristics of surrounding muscles during deep jumps at different heights and distances [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(8): 1211-1218. |

| [4] | Xiong Bohan, Yu Yang, Lu Xiaojun, Wang Xu, Yang Tengyun, Zhang Yaozhang, Liao Xinyu, Zhou Xiaoxiang, He Lu, Li Yanlin. Research progress in promoting tendon to bone healing during anterior cruciate ligament reconstruction [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(5): 779-786. |

| [5] | Wei Bo, Yao Qingqiang, Tang Cheng, Li Xuxiang, Xu Yan, Wang Liming. Advantage of medial pivot prosthesis in total knee arthroplasty via medial subvastus approach [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(4): 552-557. |

| [6] | Li Shihao, Li Qi, Li Zhen, Zhang Yuanyuan, Liu Miaomiao, Ouyang Yi, Xu Weiguo. Plantar pressure and gait analysis in patients with anterior cruciate ligament injury and reconstruction [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(4): 626-631. |

| [7] | Pan Zhengye, Ma Yong, Zheng Weitao. Finite element analysis of knee joint injury under different arm swinging modes and touchdown postures in standing long jump [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(36): 5778-5783. |

| [8] | Chen Peng, Wang Ling, Dong Shiyu, Ding Yue, Jia Shaohui, Kou Xianjuan, Zheng Cheng. Effects of whole-body vibration training on anterior cruciate ligament reconstruction: a meta-analysis [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(36): 5875-5883. |

| [9] | Wang Hao, Ma Chenghao, Qin Zuohai, Zhou Haibo, Ding Haoyuan, Han Dapeng, Nie Zhixing, Pan Peijun, Gao Chenxin, Ouyang Guilin. Effect of tourniquet use on perioperative blood loss in total knee arthroplasty in patients with rheumatoid arthritis [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(31): 4943-4948. |

| [10] | Chen Jianchao, Song Huiping. Distribution characteristics of bone mass in different parts of postmenopausal women with knee osteoarthritis [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(31): 5035-5039. |

| [11] | Li Haoran, Huang Jian. Application of finite element analysis in artificial knee arthroplasty [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(31): 5058-5063. |

| [12] | Xiang Furong, Tang Shengxin, Ou Lizhen, Lin Xikai, Chen Jian. Effects of different taping methods on knee joint stress during drop jump landing [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(30): 4850-4855. |

| [13] | Shao Yixin, Guan Tianmin, Zhu Ye, Lin Bing, Guo Chongyang, Pan Ting. Stress analysis between implant prostheses with different moduli and surrounding bones [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(29): 4612-4619. |

| [14] | Chen Changmei, Zeng Xianchun, Wang Rongpin, Wu Jiahong. Sex and age differences in the anatomical parameters of normal knee joints evaluated by X-ray [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(29): 4647-4651. |

| [15] | An Yishuai, Zhang Junxia, Li Hui, Zhang Yuxiao, Xu Guoliang, Gao Kun, Yu Shuhan, Liu Zelong. Synergistic characteristics of lower extremity muscles with unilateral knee flexion limitation [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(29): 4704-4711. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||