Chinese Journal of Tissue Engineering Research ›› 2015, Vol. 19 ›› Issue (51): 8253-8258.doi: 10.3969/j.issn.2095-4344.2015.51.010

Previous Articles Next Articles

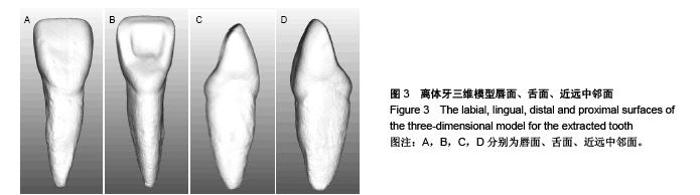

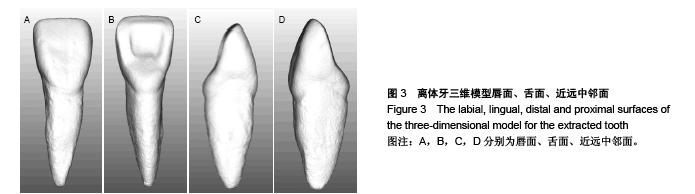

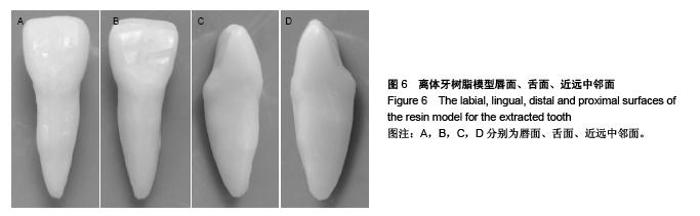

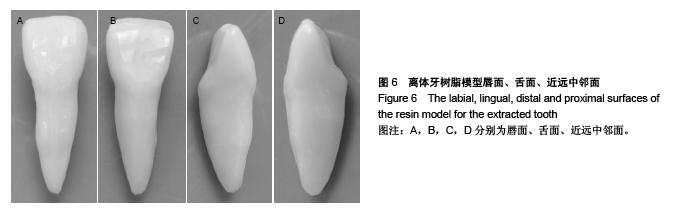

Establishing the standard test model of maxillary central incisor using CAD/CAM technology

Nie Er-min1, Xu Hui-yong2, Jiang Rui1, Yang Qiu-yuan3, Zhang Chun-yuan1, Tan Ji-zhou1

- 1Department of Stomatology, the First Affiliated Hospital of Sun Yat-sen University, Guangzhou 510080, Guangdong Province, China; 2Department of Stomatology, Nanfang Hospital, Southern Medical University, Guangzhou 510515, Guangdong Province, China; 3Wilihao Medical Devices Co., Ltd., Guangzhou 511495, Guangdong Province, China

-

Received:2015-10-28Online:2015-12-10Published:2015-12-10 -

Contact:Zhang Chun-yuan, Master, Professor, Department of Stomatology, the First Affiliated Hospital of Sun Yat-sen University, Guangzhou 510080, Guangdong Province, China -

About author:Nie Er-min, Master, Attending physician, Department of Stomatology, the First Affiliated Hospital of Sun Yat-sen University, Guangzhou 510080, Guangdong Province, China Xu Hui-yong, M.D., Attending physician, Department of Stomatology, Nanfang Hospital, Southern Medical University, Guangzhou 510515, Guangdong Province, China Nie Er-min and Xu Hui-yong contributed equally to this work. -

Supported by:the Social Development Project of Guangdong Provincial Science and Technology Department, No. 2011B080701010, 2011B080701086, 2012B061700066

CLC Number:

Cite this article

Nie Er-min, Xu Hui-yong, Jiang Rui, Yang Qiu-yuan, Zhang Chun-yuan, Tan Ji-zhou. Establishing the standard test model of maxillary central incisor using CAD/CAM technology[J]. Chinese Journal of Tissue Engineering Research, 2015, 19(51): 8253-8258.

share this article

| [1] 王太勇,乔志峰,韩志国,等.高档数控装备的发展趋势[J].中国机械工程,2011,22(10):1247-1252. [2] 杨兆军,陈传海,陈菲,等.数控机床可靠性技术的研究进展[J].机械工程学报,2013,49(20):130-139. [3] 商丽娟,吴岩,徐永军.CAD/CAM氧化锆全瓷冠修复对牙周组织的影响[J]. 中国组织工程研究, 2014,18(30):4808-4809. [4] 刘丽娜,杨敏,哈斯•巴根,等.牙种植定位导向模板的计算机辅助设计和制作[J]. 中国组织工程研究,2012,16(4):665-668. [5] Vojdani M, Torabi K, Farjood E, et al. Comparison the Marginal and Internal Fit of Metal Copings Cast from Wax Patterns Fabricated by CAD/CAM and Conventional Wax up Techniques.J Dent.2013;14(3):118-129. [6] 唐通鸣,邓佳文,张政,等.基于逆向工程和快速成型技术的髋骨三维实体模型个性化重建[J].中国组织工程研究,2015,19(26): 4253-4257. [7] 向梅,张宇.种植导板的设计制作及临床应用前景[J].中国组织工程研究,2015,19(3):488-492. [8] 吕培军,孙玉春.口腔修复计算机辅助设计/制作的过去、现在和将来[J].北京大学学报:医学版,2010,42(1):14-19. [9] Fasbinder DJ. Computerized technology for restorative dentistry. Am J Dent 2013;26(3):115-120. [10] George FM,Chan HL,Razzoog ME,et al.Fabrication of a cast-based implant surgical guide using guide sleeves.J Prosthet Dent.2011;106(6):409-412. [11] Zhao XZ,Xu WH,Tang ZH,et al.Accuracy of computer-guided implant surgery by a CAD/CAM and laser scanning technique.Chin J Dent Res.2014;17(1):31-36. [12] Moslehifard E,Nokar S.Designing a custom made gauge device for application in the access hole correction in the dental implant surgical guide.J Indian Prosthodont Soc. 2012;12(2):123-129. [13] D'Haese J,Van De Velde T,Komiyama A,et al.Accuracy and complications using computer-designed stereolithographic surgical guides for oral rehabilitation by means of dental implants: a review of the literature.Clin Implant Dent Relat Res. 2012;14(3):321-335. [14] Vieira DM,Sotto-Maior BS,Barros CA,et al.Clinical accuracy of flapless computer-guided surgery for implant placement in edentulous arches.Int J Oral Maxillofac Implants.2013;28(5): 1347-1351. [15] 赵昕,战德松. CAD/CAM系统及可切削材料在口腔修复的应用现状[J].中国实用口腔科杂志,2013,6(6):331-337. [16] 李晓萌,高平.牙科CAD/CAM系统的主要技术构成及研究现状[J].口腔颌面修复学杂志,2005,6(4):299-301. [17] Duret F, Blouin JL, Duret B.CAD-CAM in dentistry.J Am Dent Assoc. 1988;117(6):715-720. [18] Young JM, Altschuler BR.Laser holography in dentistry.J Prothet Dent.1977; 38(2):216-225. [19] 高勃,王忠义,张少锋,等. 光栅变形条纹直接分析法用于牙冠形状的三维测量-正交验波法[J]. 实用口腔医学杂志,1998;14(2): 125-128. [20] 张俐,孟宇,张大全.新型水基着色探伤剂的性能研究[J]. 上海电力学院学报,2013,29(5):485-488. [21] Lee JH, Sohn DS, Lee CH. Fabricating a fiber-reinforced post and zirconia core with CAD/CAM technology.J Prosthet Dent. 2014;112(3):683-685. [22] Zandinejad A, Metz M, Stevens P,et al.Virtually designed and CAD/CAM-fabricated lithium disilicate prostheses for an esthetic maxillary rehabilitation:A senior dental student clinical report.J Prosthet Dent.2015;113(4):382-388. [23] Ciocca L, Ragazzini S, Fantini M,et al.Work flow for the prosthetic rehabilitation of atrophic patients with a minimal- intervention CAD/CAM approach. J Prosthet Dent.2014; 114(1): 22-26. [24] Lin WS, Chou JC, Metz MJ,et al.Use of intraoral digital scanning for a CAD/CAM-fabricated milled bar and superstructure framework for an implant-supported, removable complete dental prosthesis. J Prosthet Dent.2015; 113(6):509-515. [25] da Cunha LF, Mukai E, Hamerschmitt RM, et al. Fabrication of lithium silicate ceramic veneers with a CAD/CAM approach: A clinical report of cleidocranial dysplasia. J Prosthet Dent. 2015;113(5):355-359. [26] 李爽.计算机辅助设计与制造二氧化锆全瓷冠修复体:稳定性及生物相容性[J].中国组织工程研究,2015,19(34):5491-5495. [27] 刘小舟,吕培军,王勇.口腔可切削材料的研究进展[J]. 北京大学学报:医学版,2008,40(6):654-657. [28] Nguyen JF, Migonney V, Ruse ND,et al. Resin composite blocks via high-pressure high-temperature polymerization. Dent Mater.2012;28(5):529-534. [29] Della Bona A, Corazza PH, Zhang Y. Characterization of a polymer-infiltrated ceramic-network material. Dent Mater. 2014;30(5):564-569. [30] Takahashi H, Finger WJ, Endo T,et al. Comparative evaluation of mechanical characteristics of nanofiller containing resin composites. Am J Dent.2011;24(5):264-270. [31] Lauvahutanon S, Takahashi H, Shiozawa M, et al. Mechanical properties of composite resin blocks for CAD/CAM. Dent Mater J.2014;33(5):705-710. |

| [1] | Chen Ziyang, Pu Rui, Deng Shuang, Yuan Lingyan. Regulatory effect of exosomes on exercise-mediated insulin resistance diseases [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(25): 4089-4094. |

| [2] | Chen Yang, Huang Denggao, Gao Yuanhui, Wang Shunlan, Cao Hui, Zheng Linlin, He Haowei, Luo Siqin, Xiao Jingchuan, Zhang Yingai, Zhang Shufang. Low-intensity pulsed ultrasound promotes the proliferation and adhesion of human adipose-derived mesenchymal stem cells [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(25): 3949-3955. |

| [3] | Yang Junhui, Luo Jinli, Yuan Xiaoping. Effects of human growth hormone on proliferation and osteogenic differentiation of human periodontal ligament stem cells [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(25): 3956-3961. |

| [4] | Sun Jianwei, Yang Xinming, Zhang Ying. Effect of montelukast combined with bone marrow mesenchymal stem cell transplantation on spinal cord injury in rat models [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(25): 3962-3969. |

| [5] | Gao Shan, Huang Dongjing, Hong Haiman, Jia Jingqiao, Meng Fei. Comparison on the curative effect of human placenta-derived mesenchymal stem cells and induced islet-like cells in gestational diabetes mellitus rats [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(25): 3981-3987. |

| [6] | Hao Xiaona, Zhang Yingjie, Li Yuyun, Xu Tao. Bone marrow mesenchymal stem cells overexpressing prolyl oligopeptidase on the repair of liver fibrosis in rat models [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(25): 3988-3993. |

| [7] | Liu Jianyou, Jia Zhongwei, Niu Jiawei, Cao Xinjie, Zhang Dong, Wei Jie. A new method for measuring the anteversion angle of the femoral neck by constructing the three-dimensional digital model of the femur [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3779-3783. |

| [8] | Meng Lingjie, Qian Hui, Sheng Xiaolei, Lu Jianfeng, Huang Jianping, Qi Liangang, Liu Zongbao. Application of three-dimensional printing technology combined with bone cement in minimally invasive treatment of the collapsed Sanders III type of calcaneal fractures [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3784-3789. |

| [9] | Qian Xuankun, Huang Hefei, Wu Chengcong, Liu Keting, Ou Hua, Zhang Jinpeng, Ren Jing, Wan Jianshan. Computer-assisted navigation combined with minimally invasive transforaminal lumbar interbody fusion for lumbar spondylolisthesis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3790-3795. |

| [10] | Hu Jing, Xiang Yang, Ye Chuan, Han Ziji. Three-dimensional printing assisted screw placement and freehand pedicle screw fixation in the treatment of thoracolumbar fractures: 1-year follow-up [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3804-3809. |

| [11] | Shu Qihang, Liao Yijia, Xue Jingbo, Yan Yiguo, Wang Cheng. Three-dimensional finite element analysis of a new three-dimensional printed porous fusion cage for cervical vertebra [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3810-3815. |

| [12] | Wang Yihan, Li Yang, Zhang Ling, Zhang Rui, Xu Ruida, Han Xiaofeng, Cheng Guangqi, Wang Weil. Application of three-dimensional visualization technology for digital orthopedics in the reduction and fixation of intertrochanteric fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3816-3820. |

| [13] | Sun Maji, Wang Qiuan, Zhang Xingchen, Guo Chong, Yuan Feng, Guo Kaijin. Development and biomechanical analysis of a new anterior cervical pedicle screw fixation system [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3821-3825. |

| [14] | Lin Wang, Wang Yingying, Guo Weizhong, Yuan Cuihua, Xu Shenggui, Zhang Shenshen, Lin Chengshou. Adopting expanded lateral approach to enhance the mechanical stability and knee function for treating posterolateral column fracture of tibial plateau [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3826-3827. |

| [15] | Zhu Yun, Chen Yu, Qiu Hao, Liu Dun, Jin Guorong, Chen Shimou, Weng Zheng. Finite element analysis for treatment of osteoporotic femoral fracture with far cortical locking screw [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3832-3837. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||