Chinese Journal of Tissue Engineering Research ›› 2025, Vol. 29 ›› Issue (33): 7165-7172.doi: 10.12307/2025.847

Previous Articles Next Articles

Effects of lateral screw-rod placement positions on segmental range of motion, internal fixation and cage stress during oblique lumber interbody fusion

Ma Tao1, Li Xing1, Wei Yajun2, Deng Juncai2

- 1Clinical Medical College of Chengdu University of TCM, Chengdu 610075, Sichuan Province, China; 2Department of Spinal Surgery, No.3 Affiliated Hospital of Chengdu University of TCM (West District), Chengdu 611730, Sichuan Province, China

-

Received:2024-07-09Accepted:2024-09-14Online:2025-11-28Published:2025-04-12 -

Contact:Deng Juncai, MS, Associate professor, Master’s supervisor, Department of Spinal Surgery, No.3 Affiliated Hospital of Chengdu University of TCM (West District), Chengdu 611730, Sichuan Province, China -

About author:Ma Tao, Master candidate, Clinical Medical College of Chengdu University of TCM, Chengdu 610075, Sichuan Province, China -

Supported by:Sichuan Provincial Administration of Traditional Chinese Medicine Special Research Project, No. 2023MS031 (to DJC); Chengdu University of Traditional Chinese Medicine “Xinglin Scholar” Discipline Talent Research Promotion Program, No. YYZX2022091 (to DJC)

CLC Number:

Cite this article

Ma Tao, Li Xing, Wei Yajun, Deng Juncai. Effects of lateral screw-rod placement positions on segmental range of motion, internal fixation and cage stress during oblique lumber interbody fusion[J]. Chinese Journal of Tissue Engineering Research, 2025, 29(33): 7165-7172.

share this article

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

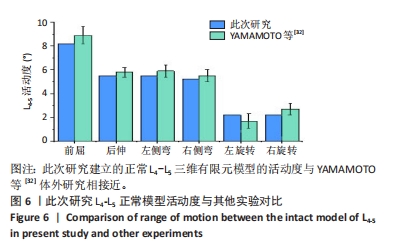

2.2 L4-5活动度比较 表2展示了各内固定模型的L4-5活动度,与Stand-Alone模型相比,所有内固定模型各工况下活动度均有所下降。双钉棒模型中Model E具有最小的活动度,单钉棒模型中Model J的活动度最小,两者内固定均贴近椎体上终板处放置。Model E在屈伸、左右侧弯、左右旋转工况下活动度分别较Stand-Alone模型下降了48.0%,47.1%,76.9%,65.7%,50.0%及42.1%,Model J分别下降了33.0%,29.8%,69.2%,60.0%,40.9%及26.3%。Model E 的各工况下活动度小于Model J,在屈伸、左右侧弯、左右旋转下分别较Model J低22.4%,24.7%,25.0%,14.3%,15.4%及21.4%。双钉棒中Model E-I相较于与之对应的单钉棒Model J-N整体活动度更小,其中Model I和Model J的活动度最大,两者均未贴近终板。由于为左侧置钉,各模型左侧弯活动度均低于右侧弯,双钉棒较单钉棒限制更多,其中Model E左侧弯活动度较右侧弯低25.0%,Model J左侧弯活动度较右侧弯低14.3%。"

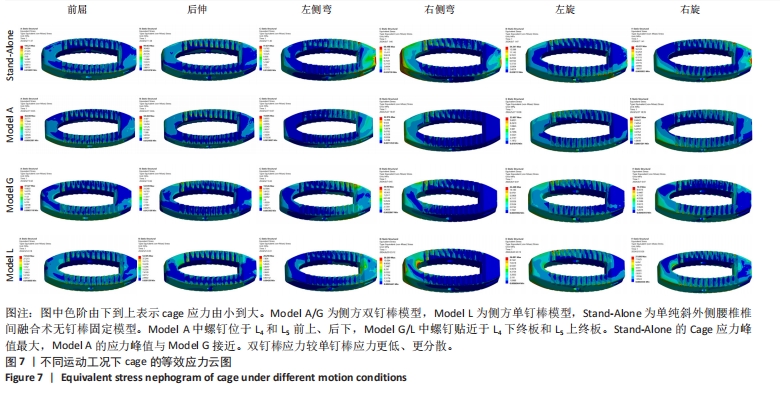

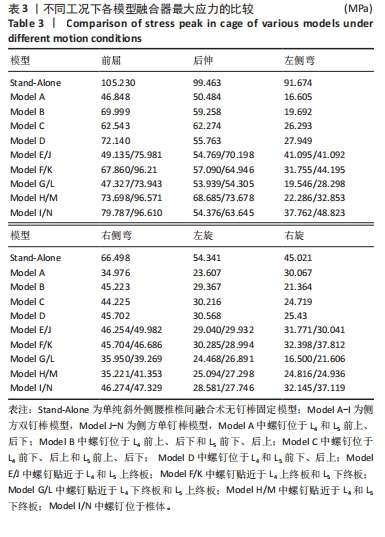

2.3 cage应力峰值比较 表3展示了各模型不同工况下cage的应力峰值,所有内固定模型各工况下cage应力峰值均小于Stand-Alone模型。在侧方双钉棒固定模型中,除右旋外,Model A在其余工况下cage的应力峰值均小于其他模型,此时的侧路双钉棒位于L4和L5前上、后下象限;Model G除右旋外各工况下的cage最大应力峰值与Model A接近,屈伸、左右侧弯、左旋工况下分别差0.479,3.455,2.941,0.974,0.861 MPa,其钉棒位置贴近L4和L5上终板处;大多数双钉棒模型的cage最大应力峰值位于前屈工况下。单钉棒固定模型中Model L各工况下的活动度最低,即钉棒贴近L4、L5椎间相邻终板放置时;单钉棒模型cage最大应力峰值均位于前屈工况下。双钉棒中Model E-I的cage应力峰值整体小于与之对应的单钉棒Model J-N。所有侧方双钉棒与单钉棒固定模型在左侧弯工况下的cage应力峰值均小于右侧弯工况。图7展示了部分内固定模型的cage等效应力分布云图。"

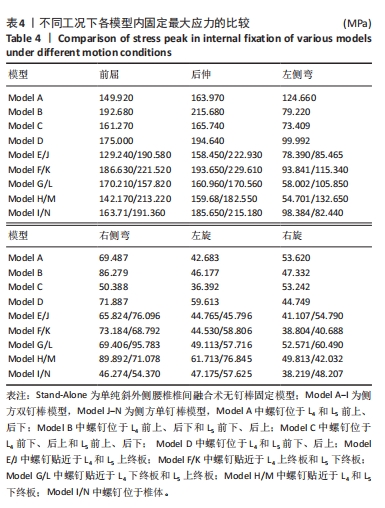

2.4 内固定应力峰值比较 表4展示了各模型内固定的应力峰值。所有模型内固定最大应力峰值均位于屈伸工况下。双钉棒固定模型中,Model E在屈伸工况下内固定峰值应力最小,分别为129.240,158.450 MPa,其在屈伸工况下内固定峰值应力均小于单钉棒模型,Model E屈伸工况下分别较Model J减少32.2 %,28.9%,较Model K减少41.7%,30.1%,较Model L减少18.1%,7.1%,较Model M减少39.4%,13.2%,较Model N减少32.5%,26.4%。在单钉棒固定模型中,Model L在屈伸工况下内固定具有最小的峰值应力,分别为157.820,170.560 MPa,Model N在左右侧弯工况下有最小内固定峰值应力。与活动度及cage应力峰值规律相一致,双钉棒中Model E-I的内固定应力峰值整体也较与之对应的单钉棒Model J-N小。大部分模型左侧弯工况下的内固定峰值应力大于右侧弯。在应力分布上,应力主要集中在螺尾及连接棒上,最大应力位于钉棒、螺钉以及钉棒与皮质骨交界处。图8展示了部分内固定模型钉棒系统屈伸工况下的等效应力分布云图。"

| [1] SOUSLIAN FG, PATEL PD. Review and analysis of modern lumbar spinal fusion techniques. Brit J Neurosurg. 2021;38(1):61-67. [2] MAYER HM. A new microsurgical technique for minimally invasive anterior lumbar interbody fusion. Spine. 1997;22(6):691-699; discussion 700. [3] SILVESTRE C, MAC-THIONG JM, HILMI R, et al. Complications and Morbidities of Mini-open Anterior Retroperitoneal Lumbar Interbody Fusion: Oblique Lumbar Interbody Fusion in 179 Patients. Asian Spine J. 2012;6(2):89-97. [4] LI X, DONG Y, ZHOU H, et al. Oblique Lumbar Interbody Fusion at L5-S1 Segment Through an Approach Between the Psoas Muscle and the Great Vessels. J Vis Exp. 2024;(203): doi: 10.3791/65684. [5] 高志扬,王京,黄毓凯,等.斜外侧入路腰椎椎间融合术的临床进展[J].中国脊柱脊髓杂志,2024,34(7):774-779. [6] 魏晋鹏,常峰.斜外侧入路腰椎椎间融合术临床应用研究进展[J].脊柱外科杂志,2023,21(1):50-56. [7] 陈胜,顾俊,王春明,等.单边腰椎斜侧方入路椎间融合术治疗腰椎退行性疾病的临床疗效分析[J].南京医科大学学报(自然科学版),2022,42(12):1750-1754. [8] LI R, LI X, ZHOU H, et al. Development and Application of Oblique Lumbar Interbody Fusion. Orthop Surg. 2020;12(2):355-365. [9] 李生鋆,范顺武,赵凤东. OLIF的临床应用与研究进展[J]. 西安交通大学学报(医学版),2022,43(1):18-24. [10] 侯坤鹏,赵泉来,吴天亮,等.斜外侧入路腰椎融合内固定的生物力学稳定性[J].中国组织工程研究,2021,25(13):5362-5368. [11] ZENG ZY, CHEN PQ, ZHAO X, et al. Analysis of the causes of cage subsidence after oblique lateral lumbar interbody fusion. Zhongguo Gu Shang. 2024;37 (1):33-44. [12] 葛鑫,徐宏光,刘晨,等.腰椎退行性病单独腰椎斜外侧椎体间融合术的并发症[J].中国矫形外科杂志,2020,28(3):193-198. [13] 高显达,马雷,赵若宇,等. 单节段斜外侧腰椎间融合术后腰痛的危险因素分析[J]. 中华骨科杂志,2021,41(18):1342-1349. [14] CAI XY, BIAN HM, CHEN C, et al. Biomechanical study of oblique lumbar interbody fusion (OLIF) augmented with different types of instrumentation: a finite element analysis. J Orthop Surg Res. 2022; 17(1):269. [15] GUO HZ, TANG YC, GUO DQ, et al. Stability evaluation of oblique lumbar interbody fusion constructs with various fixation options:A finite element analysis based on three-dimensional scanning models. World Neurosurg. 2020;138:e530-e538. [16] ZHANG S, LIU Z, LU C, et al. Oblique lateral interbody fusion combined with different internal fixations for the treatment of degenerative lumbar spine disease: a finite element analysis. BMC Musculoskelet Disord. 2022;23(1):206. [17] TARAWNEH AM, SALEM KM. A Systematic Review and Meta-analysis of Randomized Controlled Trials Comparing the Accuracy and Clinical Outcome of Pedicle Screw Placement Using Robot-Assisted Technology and Conventional Freehand Technique. Glob Spine J. 2020;11(4): 575-586. [18] HAO J, TANG X, JIANG N, et al. Biomechanical stability of oblique lateral interbody fusion combined with four types of internal fixations: finite element analysis. Front Bioeng Biotechnol. 2023;11:1260693. [19] OUYANG P, TAN Q, HE X, et al. Computational comparison of anterior lumbar interbody fusion and oblique lumbar interbody fusion with various supplementary fixation systems: a finite element analysis. J Orthop Surg Res. 2023;18(1):4. [20] WU MT, CHUNG TT, CHEN SC, et al. Oblique lateral interbody fusion in heterogenous lumbar diseases: Anterolateral screw fixation vs. posterior percutaneous pedicle screw fixation - A single center experience. Front Surg. 2022:9:989372. [21] GUO Y, WANG X, LI Y, et al. Oblique Lateral Interbody Fusion with Anterolateral Screw Fixation Is as Effective as with Posterior Percutaneous Pedicle Screw Fixation in Treating Single-Segment Mild Degenerative Lumbar Diseases. Med Sci Monit. 2022;28:e934985. [22] 李柱海,曾建成,王贤帝,等.斜外侧腰椎椎间融合术联合前路内固定治疗退行性腰椎滑脱症的疗效分析[J].中国临床新医学, 2023,16(3):213-218. [23] LI R, LIU Y, ZHU Y, et al. Clinical and radiographic outcomes of oblique lumbar interbody fusion with anterolateral screw and rod instrumentation in osteopenia patients: a retrospective study. BMC Musculoskelet Disord. 2023;24(1):760. [24] KANEDA K, ABUMI K, FUJIYA M. Burst fractures with neurologic deficits of the thoracolumbar-lumbar spine. Results of anterior decompression and stabilization with anterior instrumentation. Spine. 1984;9(8): 788-795. [25] LU T, LU Y. Comparison of Biomechanical Performance Among Posterolateral Fusion and Transforaminal, Extreme, and Oblique Lumbar Interbody Fusion: A Finite Element Analysis. World Neurosurg. 2019;129:e890-e899. [26] XU H, JU W, XU N, et al. Biomechanical comparison of transforaminal lumbar interbody fusion with 1 or 2 cages by finite-element analysis. Neurosurgery. 2013;73:s198-s205. [27] 中国康复医学会脊柱脊髓专业委员会腰椎研究学组. 腰椎侧方椎间融合术应用中国专家共识[J]. 中华医学杂志,2021,101(3):199-204. [28] PAN CC, LEE CH, CHEN KH, et al. Comparative Biomechanical Analysis of Unilateral, Bilateral, and Lateral Pedicle Screw Implantation in Oblique Lumbar Interbody Fusion: A Finite Element Study. Bioengineering (Basel). 2023;10(11):1238. [29] LEE HJ, LEE SJ, JUNG JM, et al. Biomechanical Evaluation of Lateral Lumbar Interbody Fusion with Various Fixation Options for Adjacent Segment Degeneration: A Finite Element Analysis. World Neurosurg. 2023;173:e156-e167. [30] WANG T, ZHAO Y, CAI Z, et al. Effect of osteoporosis on internal fixation after spinal osteotomy: A finite element analysis. Clin Biomech. 2019; 69:178-183. [31] ZHANG S, LIU Z, LU C, et al. Oblique lateral interbody fusion combined with different internal fixations for the treatment of degenerative lumbar spine disease: a finite element analysis. BMC Musculoskelet Disord. 2022;23(1):206. [32] YAMAMOTO I, PANJABI MM, CRISCO T, et al. Three-dimensional movements of the whole lumbar spine and lumbosacral joint. Spine. 1989;14(11):1256-1260. [33] TAO EX, ZHANG RJ, ZHANG B, et al. Biomechanical changes of oblique lumbar interbody fusion with different fixation techniques in degenerative spondylolisthesis lumbar spine: a finite element analysis. BMC Musculoskelet Disord. 2024;25(1):664. [34] 唐福波,钟远鸣,李智斐.不同钉棒内固定方式在腰椎侧路融合中的有限元力学分析[J].中国组织工程研究,2024,28(21):3293-3298. [35] CHOI YH, KWON SW, MOON JH, et al. Lateral Lumbar Interbody Fusion and in Situ Screw Fixation for Rostral Adjacent Segment Stenosis of the Lumbar Spine. J Korean Neurosurg Soc. 2017;60(6):755-762. |

| [1] | Xu Hao, Ding Lu, Li Xiao. Investigating the effect of the mechanical wear on abutment screw in Morse taper connection implant implant system by using finite element analysis [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(在线): 1-9. |

| [2] | Sun Xiaojun, Wang Huaming, Zhang Dehong, Song Xuewen, Huang Jin, Zhang Chen, Pei Shengtai. Effect of finite element method in treatment of developmental dysplasia of the hip in children [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(9): 1897-1904. |

| [3] | Li Liangkui, Huang Yongcan, Wang Peng, Yu Binsheng. Effect of anterior controllable anteriodisplacement and fusion on vertebrae-ossification of posterior longitudinal ligament complex and implants: a finite element analysis [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(9): 1761-1767. |

| [4] | Xu Biao, Lu Tan, Jiang Yaqiong, Yin Yujiao. Xu Biao, Lu Tan, Jiang Yaqiong, Yin Yujiao [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(9): 1768-1774. |

| [5] | Zhou Jinhai, Li Jiangwei, Wang Xuquan, Zhuang Ying, Zhao Ying, Yang Yuyong, Wang Jiajia, Yang Yang, Zhou Shilian. Three-dimensional finite element analysis of anterior femoral notching during total knee arthroplasty at different bone strengths [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(9): 1775-1782. |

| [6] | Chen Xi, Tang Tao, Chen Tongbing, Li Qing, Zhang Wen. Mechanical stability of intertrochanteric fracture of femur with different internal fixation systems [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(9): 1783-1788. |

| [7] | Fu Enhong, Yang Hang, Liang Cheng, Zhang Xiaogang, Zhang Yali, Jin Zhongmin. OpenSim-based prediction of lower-limb biomechanical behavior in adolescents with plantarflexor weakness [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(9): 1789-1795. |

| [8] | Lu Jieming, Li Yajing, Du Peijie, Xu Dongqing. Effects of artificial turf versus natural grass on biomechanical performance of the lower limbs in young females during jump-landing [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(6): 1101-1107. |

| [9] | Li Shuai, Liu Hua, Shang Yonghui, Liu Yicong, Zhao Qihang, Liu Wen. Stress distribution on the maxilla when wearing the Twin-block appliance for Class II malocclusion [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(5): 881-887. |

| [10] | Zhou Zonghao, Luo Siyang, Chen Jiawen, Chen Guangneng, Feng Hongchao. Finite element analysis of bioabsorbable plates versus miniature titanium plates in mandibular fracture fixation in different bone qualities [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(4): 818-826. |

| [11] | Chen Yilong, Zhang Xu, Li Hong. Mechanical analysis of fiber post combined with different crown restorations for endodontically treated non-carious cervical lesions [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(4): 866-871. |

| [12] | Wang Lei, Li Chengsong, Zhang Shenshen, Wang Qing. Finite element analysis of biomechanical characteristics of three internal fixation methods in treatment of inferior patellar fracture [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(33): 7048-7054. |

| [13] | Xu Xin, Wurikaixi·Aiyiti, Lyu Gang, Maimaiaili·Yushan, Ma Zhiqiang, Ma Chao. Finite element analysis of four different internal fixation methods for complex acetabular double-column fractures [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(33): 7063-7071. |

| [14] | Liang Cheng, Zhuo Chuanchuan, Zhang Xiaogang, Wang Guan, Duan Ke, Li Zhong, Lu Xiaobo, Zhuo Naiqiang, Jin Zhongmin. Biomechanical characteristics of a novel sacroiliac lag screw [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(33): 7080-7086. |

| [15] | Ma Shuangshuang, Gao Dedong, Shan Zhongshu, Xu Wenxu, Lu Zhirui. Finite element analysis and biomechanical validation of revision pedicle screw placement [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(33): 7087-7095. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||