Chinese Journal of Tissue Engineering Research ›› 2016, Vol. 20 ›› Issue (39): 5794-5800.doi: 10.3969/j.issn.2095-4344.2016.39.003

Previous Articles Next Articles

Design, manufacture and experimental analysis of cementless hip prosthesis in torsional force transmission

Pang Bang1, Wu Qi2, Guan Xiao-dong1, Xi Wen-ming1

- 1School of Aerospace Engineering, Xiamen University, Xiamen 361005, Fujian Province, China; 2The 82 Hospital of People’s Liberation Army, Huai’an 223001, Jiangsu Province, China

-

Revised:2016-07-11Online:2016-09-23Published:2016-09-23 -

About author:Pang Bang, Studying for master’s degree, School of Aerospace Engineering, Xiamen University, Xiamen 361005, Fujian Province, China

CLC Number:

Cite this article

Pang Bang, Wu Qi, Guan Xiao-dong, Xi Wen-ming. Design, manufacture and experimental analysis of cementless hip prosthesis in torsional force transmission[J]. Chinese Journal of Tissue Engineering Research, 2016, 20(39): 5794-5800.

share this article

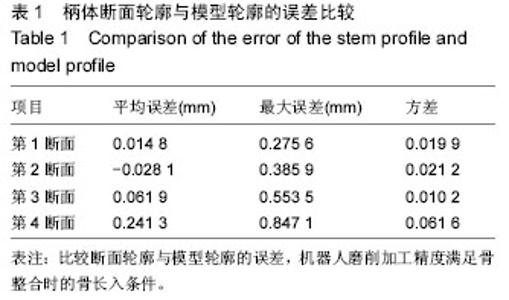

假体加工完成后,在假体从机器人末端拆下前,利用探针台配合机器人的运动,沿柄体长度方向测量柄体的四个断面,相邻断面之间的距离为10 mm。机器人每转过5°测量断面上的柄体表面的一个点,每个断面上共测量72个点,依次拟合每个断面的测量点,得到柄体断面的4个轮廓。在柄体断面的相同位置,截取柄体模型的4个断面,将相同位置的柄体断面与柄体模型断面进行比较,可得到机器人加工的误差,断面轮廓和模型轮廓间的误差见表1所示。在机器人轨迹编程时,柄体的远端和近端圆周上产生的机器人轨迹点数量相同,由于柄体远端的周长小于柄体近端的周长,随着柄体周长的增加,从柄体远端向近端的加工误差变大,增加柄体加工精度的方法是在柄体周长上产生更多的机器人加工轨迹点。在医学上,当假体与髓腔之间的间隙小于1 mm时,就认为骨组织可以长入假体表面微孔,骨与假体间不会形成纤维组织。柄体断面形状的详细测量方法与误差分析见文献[21]。"

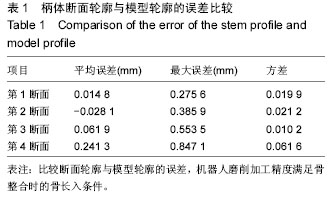

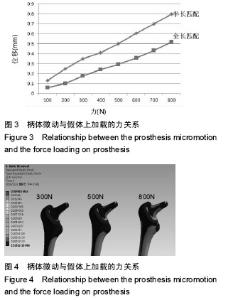

将设计的定制式假体与股骨模型导入Pro-E 软件 (Parametric Technology Company,USA)进行装配,然后,将装配好的模型导入Ansys Workbench 14.5软件(Ansys Company,USA)赋材质并进行网格划分,其中股骨的模量设置为2×1010 Pa,假体的模量设置为11× 1010 Pa。 在装配模型的假体顶端加载力,可得到柄体微动与假体上加载的力的关系。由于在有限元分析软件中无法得到柄体微动,实验采用如下的方法得到柄体微动与假体上加载力的关系:首先在股骨模型上做标记点,其次在有限元软件中剖开未加载力时股骨与假体的匹配模型,测量标记点与假体模型末端的距离,最后,在有限元软件中剖开加载不同力的股骨与假体匹配模型,测量标记点与假体模型末端的距离,将加载力的测量距离与未加载力的测量距离相减,可以得到柄体微动与假体上加载力的关系,见图3所示。在图3中,全长匹配是指柄体整个长度与髓腔匹配,而半长匹配是指柄体的一半长度与髓腔匹配。从图3可以看出,柄体的微动随着假体上加载力的增加而增加,随着柄体匹配区的增加而减小。这样,通过改变匹配区的大小,就可以控制柄体的微动,从而控制柄体的扭转微动。根据柄体断面的 0.32 (°)/mm扭转角度,得到假体近端扭转微动=微动× 0.32×假体的轴线到假体近端表面的最大距离×2π/360。参考图3中的半长匹配的微动曲线,当假体上加载300,500,800 N力时,假体近端相对髓腔的扭转微动为19.5,27.9,44.5 µm,计算时,假体的轴线到假体近端表面的最大距离是10 mm。图4是将股骨远端固定,在匹配区的柄体上加载扭转力,使柄体相对髓腔的扭转微动和计算的扭转微动相同。从图4可以看出,当假体上加载300,500,800 N力时,柄体产生的扭转微动都可以传递到股骨近端。这是因为大模量的假体总是将扭转力向远离扭转力加载点的地方传递,当扭转力加载在假体远端时,该扭转力被传递到股骨近端。"

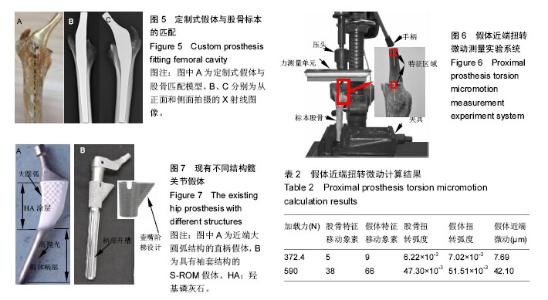

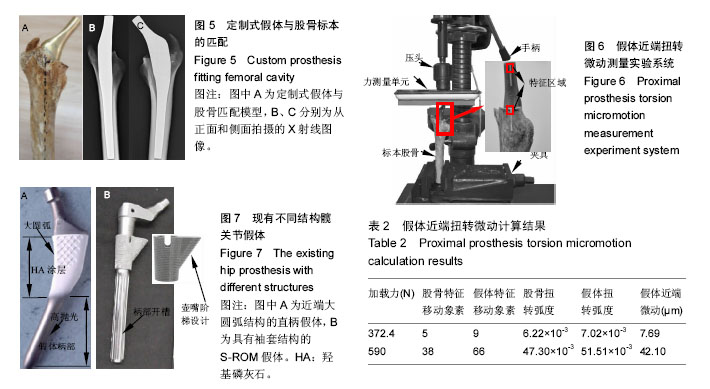

图5A是将制作的假体插入到标本股骨髓腔中的匹配图,图5B和图5C是假体与股骨髓腔匹配后的X射线图。图6是假体近端扭转微动测量实验系统,将匹配假体后的标本股骨通过夹具固定在测试系统的基座上。固定股骨时,股骨轴线与垂直线(加载在假体上的力延长线)形成13°夹角,保证假体上加载力的延长线与股骨轴线交于股骨下截面。假体顶端放置有力测量单元,通过测试系统的手柄,人工将力加载在压头上,通过力测量单元,可以获得压头加载在假体上的力。当力加载在假体上时,利用相机拍摄图片,采用图像处理方法计算假体和股骨上特征点的移动象素,通过特征点的移动象素分别计算假体和股骨的旋转角度β1和β2(单位为弧度),将假体的旋转角度减去股骨的旋转角度,得到假体相对股骨的旋转角度β1-β2,测量假体近端表面到假体轴线的最大距离r,则假体相对股骨的扭转微动为(β1-β2)×r,扭转微动的计算结果见表2所示。"

| [1] Benum P,Aamodt A.Uncemented custom femoral components in hip arthroplasty - A prospective clinical study of 191 hips followed for at least 7 years. Acta orthopaedica. 2010;81(4):427-435. [2] Pattyn C, Mulliez A,Verdonk R,et al.Revision hip arthroplasty using a cementless modular tapered stem. Int Orthop.2012;36:35-41. [3] Delaunay C.Effect of hydroxyapatite coating on the radio-clinical results of a grit-blasted titanium alloy femoral taper. A case-contro; study of 198 cementless primary total hip arthroplasty with the alloclassicTM system.Orthop Traumatol Surg Res.2014;100:739-744. [4] Farfalli GL,Boland PJ,Morris GD,et al.Early equivalence of uncemented press-fit and compress femoral fixation.Clin Orthop Relat Res.2009;467:2792-2799. [5] Denaro V,Fornasier VL.Hip joint replacement implant- fit versus conformation.Eur J Orthop Surg Traumatol. 1999;9:1-8. [6] Ruben RB,Fernandes PR,Folgado J.On the optimal shape of hip implants. J Biomech.2012;45:239-246. [7] Lee TC,Taylor D.Bone remodelling: should we cry Wolff? Ir J Med Sci.1999; 168(2):102-105. [8] Mullender MG,Huiskes R.Proposal for the regulatory mechanism of Wolff's law.J Orthop Res.1995;13(4): 503-512. [9] Kress AM,Schmidt R,Nowak TE,et al.Stress-related femoral cortical and cancellous bone density loss after collum femoris preserving uncementrf total hip arthroplasty: prospective 7-year follow-up with quantitative computed tomography.Arch Orthop Trauma Surg.2012;132:1111-1119. [10] Huiskes R,Weinans H,Grootenboer HJ,et al.Adaptive bone-remodeling theory applied to prosthetic-design analysis.J Biomechanics.1987;20(1112):1135-1150. [11] Pyburn E,Goswami T.Finite element analysis of femoral components paper III-hip joints.Mater Design. 2004;25:705-713. [12] Fraldi M,Esposito L,Perrella G,et al.Topological optimization in hip prosthesis design.Biomech Model Mechanobiol.2010;9:389-402. [13] Sabatini AL,Goswami T.Hip implants VII: Finite element analysis and optimization of cross-sections.Mater Design.2008;29:1438-1446. [14] Hartzband MA,Glassman AH,Goldberg VM,et al.Survivorship of a low-stiffness extensively porous-coated femoral stem at 10 years.Clin Orthop Relat Res.2010;468: 433-440. [15] Van der Wal BCH,De Kramer BJ,Grimm B,et al.Femoral fit in ABG-II hip stem, influence on clinical outcome and bone remodeling: a radiographic.Arch Orthop Trauma Surg. 2008;128:1065-1072. [16] Flecher X,Pearce O,Parratte S,et al.Custom cementless stem improves hip function in young patients at 15-year followup.Clin Orthop Relat Res. 2010;468:747-755. [17] Kharmanda G.Reliability analysis for cementless hip prosthesis using a new optimized formulation of yield stress against elasticity modulus relationship. Mater Design.2015;65:496-504. [18] Stihsen C,Radl R,Keshmiri A,et al.Subsidence of a cementless femoral component influenced by body weight and body mass index.Int Orthop.2012;36: 941-947. [19] 汪伟,王岩,崔健,等.股骨近端三维几何形态重建[J].中华外科杂志,2003,41(10):744-748. [20] Xi WM,Wang AM,Wu Q,et al.An integrated CAD/CAM/robotic milling method for custom cementless femoral prostheses.Med Eng Phys.2015; 37:911-915. [21] 韩文龙,朱建非,吴琪,等.CAD/CAM/Robotic集成方法设计与制作生物型股骨柄假体[J].中国组织工程研究,2014, 18(40):6413-6418. [22] Pettersen SH,Wik TS,Skallerud B.Subject specific finite element analysis of implant stability for a cementless femoral stem.Clin Biomech.2009;24: 480-487. [23] Ostbyhaug PO,Klaksvik J,Romundstad P,et al.Primary stability of custom and anatomical uncemented femoral stems. A method for three-dimensional in vitro measurement of implant stability.Clin Biomech. 2010; 25: 318-324. [24] Gortchacow M,Wettstein M,Pioletti DP,et al.A new technique to measure micromotion distribution around a cementless femoral stem.J Biomech.2011;44:557-560. [25] Nakamura Y,Ohishi H,Kishiya N,et al.Total hip arthroplasty with an HPF stem: the radiological findings around the cementless anatomical-shape stem for developmental dysplasia of the hip.J Orthop Sci.2011;16:364-368. [26] Taylor RH,Mittelstadt BD,Paul HA,et al.An image-directed robotic system for precise orthopaedic surgery.IEEE transaction on robotics and antomation. 1994;10(3): 261-275. [27] Reimeringer M,Nuño N,Desmarais-Trépanier C,et al.The influence of uncemented femoral stem length and design on its primary stability: A finite element analysis. Comput Method Biomech Biomed Eng. 2013;16(11):1221-1231. [28] Gortchacow M,Wettstein M,Pioletti DP,et al .Simultaneous and multisite measure of micromotion, subsidence and gap to evaluate femoral stem stability. J Biomech.2012;45:1232-1238. [29] Oshkour AA,Talebi H,Shirazi SFS,Parametric study of radial functionally graded femoral prostheses with different geometries.Meccanica.2015;50:1657-1678. [30] Campbell M,Denault J,Yahia LH,et al.CF/PA12 composite femoral stems: Manufacturing and properties.Composites: Part A.2008;39:796-804. [31] Chow I,Patel RM,Stulberg SD.Short stem metaphyseal-engaging femoral implants: a case-controlled radiographic and clinical evaluation with eight year follow-up.J Arthroplasty.2015;30:600-606. [32] Budde S,Seehaus F,Schwarze M,et al.Analysis of migration of the Nanos short-stem hip implant within two years after surgery.Int Orthop(SICOT).Published online, 2015:1-8. [33] Vasseur L,Ayoub B,Mesnil P,et al.Femoral lengthening during hip resurfacing arthroplasty: A new surgical procedure.Orthop Traumatol Surg Res.2015;101:247-249. [34] Le D,Smith K,Tanzer D,et al.Modular femoral sleeve and stem implant provides long-term total hip survivorship.Clin Orthop Relat Res.2011;469:508-513. [35] Baharuddin MY,Salleh SH,Zulkifly AH,et al.Design process of cementless femoral stem using a nonlinear three dimensional finite element analysis. BMC Musculoskeletal Disorders.2014;15(30):1-17. [36] Rawal BR,Ribeiro R,Malhotra R,et al.Design and manufacturing of femoral stems for the Indian population.J Manufact Proc.2012;14:216-223. [37] Pawlikowski M,Skalski K,Haraburda M.Process of hip joint prosthesis design including bone remodeling phenomenon.Comput Struct.2003;81:887-893. [38] Grochola LF,Habermann B,Mastrodomenico N,et al. Comparison of periprosthetic bone remodelling after implantation of anatomic and straight stem prostheses in total hip arthroplasty.Arch OrthopTrauma Surg.2008; 128:383-392. |

| [1] | Shi Bin, An Jing, Chen Long-gang, Zhang Nan, Tian Ye . Influencing factors for pain after total knee arthroplasty [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 993-997. |

| [2] | Wang Xian-xun. Impact of local compression cryotherapy combined with continuous passive motion on the early functional recovery after total knee arthroplasty [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 998-1003. |

| [3] | Yuan Wei, Zhao Hui, Ding Zhe-ru, Wu Yu-li, Wu Hai-shan, Qian Qi-rong. Association between psychological resilience and acute mental disorders after total knee arthroplasty [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1015-1019. |

| [4] | Chen Qun-qun, Qiao Rong-qin, Duan Rui-qi, Hu Nian-hong, Li Zhao, Shao Min. Acu-Loc®2 volar distal radius bone plate system for repairing type C fracture of distal radius [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1025-1030. |

| [5] | Huang Xiang-wang, Liu Hong-zhe. A new low elastic modulus of beta titanium alloy Ti2448 spinal pedicle screw fixation affects thoracic stability: biomechanical analysis [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1031-1035. |

| [6] | Xie Qiang. Three-dimensional finite element model for biomechanical analysis of stress in knee inversion and external rotation after posterior cruciate ligament rupture [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1036-1040. |

| [7] | He Ze-dong, Zhao Jing, Chen Liang-yu, Li Ke, Weng Jie. Multilevel finite element analysis on the biological tribology damage of water on bone tissue [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1041-1045. |

| [8] | Jiang Zi-wei, Huang Feng, Cheng Si-yuan, Zheng Xiao-hui, Sun Shi-dong, Zhao Jing-tao, Cong Hai-chen,Sun Han-qiao, Dong Hang. Design and finite element analysis of digital splint [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1052-1056. |

| [9] | Wang Fei, Liu Zhi-bin, Tao Hui-ren, Zhang Jian-hua, Li Chang-hong, Cao Qiang, Zheng Jun, Liu Yan-xiong, Qu Xiao-peng. Clinical efficacy of preoperative osteotomy designs using paper-cut technology versus photoshop software for ankylosing spondylitis with kyphosis [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1057-1063. |

| [10] | Li Hui, Ma Jun-yi, Ma Yuan, Zhu Xu . Establishment of a three-dimensional finite element model of ankylosing spondylitis kyphosis [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1069-1073. |

| [11] | Ling Guan-han, Ou Zhi-xue, Yao Lan, Wen Li-chun, Wang Guo-xiang, Lin Heng-feng. Establishment of simulating three-dimensional model of China-Japan Friendship Hospital Classification for L type osteonecrosis of the femoral head [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1074-1079. |

| [12] | Fu Wei-min, Wang Ben-jie. Assessing the degree of necrotic femoral head, and association of blood supply with pathlogical changes: study protocol for a diagnostic animal trial [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1086-1091. |

| [13] | Zhang Wen-qiang, Ding Qian, Zhang Na. Associations between alpha angle and herniation pit on oblique axial magnetic resonance imaging in asymptomatic hip joints of adults [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1098-1103. |

| [14] | Sun Xiao-xin1, Zhou Wei2, Zuo Shu-ping3, Liu Hao1, Song Jing-feng1, Liang Chun-yu1. Morphological characteristics for the magnetic resonance imaging assessment of discoid lateral meniscal tears in children [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1104-1109. |

| [15] | Lin Han-wen, Wen Jun-mao, Huang Chao-yuan, Zhou Chi, Tang Hong-yu. Correlation between the changes in lower limb power line and pain area in the knee osteoarthritis patients: imaging evaluation [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1110-1114. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||