Chinese Journal of Tissue Engineering Research ›› 2016, Vol. 20 ›› Issue (48): 7169-7174.doi: 10.3969/j.issn.2095-4344.2016.48.004

Previous Articles Next Articles

Optimization design and simulation analysis of artificial atlanto-odontoid joint structure

Xiong Sheng1, Chen Xi-liang1, Wang Yun-feng1, Hu Yong2

- 1Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo 315201, Zhejiang Province, China; 2Ningbo Sixth Hospital, Ningbo 315000, Zhejiang Province, China

-

Revised:2016-09-10Online:2016-11-25Published:2016-11-25 -

Contact:Chen Xi-liang, M.D., Researcher, Doctoral supervisor, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo 315201, Zhejiang Province, China -

About author:Xiong Sheng, Master, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo 315201, Zhejiang Province, China

CLC Number:

Cite this article

Xiong Sheng, Chen Xi-liang, Wang Yun-feng, Hu Yong. Optimization design and simulation analysis of artificial atlanto-odontoid joint structure[J]. Chinese Journal of Tissue Engineering Research, 2016, 20(48): 7169-7174.

share this article

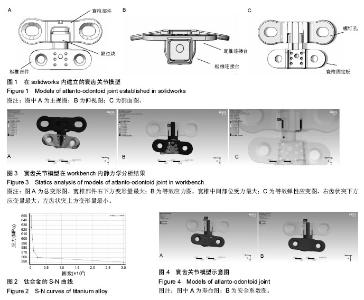

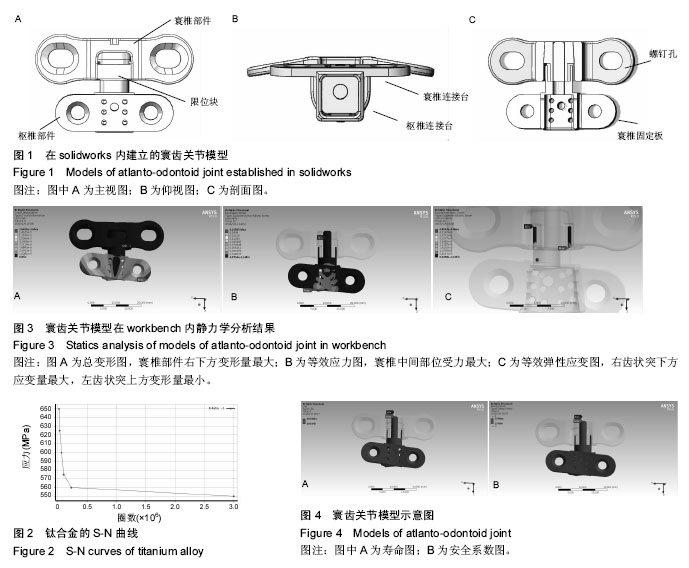

2.1 寰枢椎关节有限元模型的特点 实验建立的寰枢椎关节有限元模型外观逼真,与实物几何相似性好。寰枢部位、旋转轴套和限位块共包含19 088个节点, 10 288个单元;枢椎部位共包含15 957个节点,8 254个单元。通过对模型进行大致的实验和分析可知,模型在正常和旋转工况下各部位体外实验结果和模型在相似载荷和边界条件下的结果大体相同,应力云图与优化前的对比也验证了模型的可行性和优越性。 2.2 寰枢椎关节有限元模型的数据分析结果 通过对改进后的寰齿关节模型进行力学分析和疲劳分析后得到的具体数据可知:由图3A知当对寰齿关节模型施加0.5 N•m的转矩后,模型最大变形在右侧固定板的右下角处,为1.645 3×10-5 mm,前弓板的孔右下侧变形为0;由图3B知固定板的最小应力集中在中心轴上,为4.775 6×10-11 Mpa,最大应力集中在枢椎连接台底部,为0.07 MPa;由图3C知齿状突的弹性应变较小,为6.643 8×10-12-4.856 2×10-8 mm/mm,此数据皆满足要求,故不会发生断裂;由图4A知进行疲劳分析后可知寰齿关节模型关键部位齿状突的疲劳寿命为3×106 cycles;由图4B知寰枢关节模型的安全系数为最大值15。由仿真分析结果可知,此寰枢关节模型的安全系数为15;按1个正常成年人寰枢关节每天运动200 cycles计算,可知此寰枢关节模型可正常使用40年以上;绕枢椎连接台中心轴施加0.5 N•m转矩后,寰枢关节模型所受应力为(0.07-4.78)×10-11 MPa。前路经寰枢关节锁定钛板内固定下应力集中部位主要为螺钉经枢椎连接台底部及钉孔部,其最大值出现在枢椎连接台底部,应力大小为0.07 MPa。综上可知,优化后的寰枢关节模型的安全性能,疲劳寿命和强度均满足要求。"

| [1] 杨明浩,高文雷,金乾坤,等.颅颈交界区畸形寰枢外侧关节生物力学稳定性的有限元分析[J].重庆医学,2015,44(29): 4070-4072.[2] 胡勇,赵红勇,谢辉,等.人工寰齿关节置换后寰枢关节有限元模型的建立及其有效性验证[C].2013中国工程院科技论坛暨浙江省骨科学学术年会论文摘要集.2013.[3] 胡勇,赵红勇,谢辉,等.人工寰齿关节置换后寰枢关节有限元模型的建立[J].中华实验外科杂志, 2013,30(7):1422-1424.[4] 胡勇,何贤嶂,徐荣明,等.人工寰齿全关节置换后对寰枢关节稳定性和三维运动生物力学评价[J].中华实验外科杂志,2009,26(6):715-717.[5] 卢一生,贾连顺.寰枢关节的三维运动规律及其测量[J].中华创伤杂志,1995,21(1):1-3.[6] 杨生,孟春玲,王鹏,等.枕寰枢复合体有限元模型的建模研究[J].计算机仿真,2011, 28(1):268-272.[7] 丁欣.上颈椎三维有限元模型的建立与分析[D].厦门:厦门大学,2014.[8] 王小平.上颈椎损伤的有限元模型研究[D].汕头:汕头大学, 2008.[9] 王雷,柳超,田纪伟,等.寰枢椎复合体三维有限元模型的建立与寰枢椎复合骨折机制的有限元分析[J].中国矫形外科杂志,2012,20(24):2276-2279.[10] Qin ZY, Yan SZ, Chu FL, et al. Dynamic analysis of clamp band joint system subjected to axial vibration. J Sound Vibration. 2010;329(21):4486-4500.[11] Serveto S, Mariot JP, Diaby M, et al. Modelling and measuring the axial force generated by tripod joint of automotive drive-shaft. Multibody System Dynamics. 2008;19(3):209-226.[12] Chans DO, Cimadevila JE, Gutiérrez EM, et al. Model for predicting the axial strength of joints made with glued-in rods in sawn timber. Construction Building Materials. 2010;24(9):1773-1778.[13] Chang W, Alexander MS. Diagnostic determinants of craniocervical distraction injury in adults. Am J Roentgenol. 2009;192(1):52-58.[14] 袁嘉阳,王华,薛刚,等.桡侧腕掌屈肌伴掌长肌副腱一例[J].解剖学研究,2014,36(1):76-76.[15] 胡勇,杨述华,谢辉,等.人工寰齿关节设计依据及可行性分析[J].中国骨伤,2007, 20(9):587-591.[16] Zang Q, Liu Y, Wang D, et al. An Experimental Biomechanical Study on Artificial Atlanto-odontoid Joint Replacement in Dogs. Clin Spine Surg. 2016.[17] Hu Y, Dong WX, Hann S, et al. Construction of Finite Element Model for an Artificial Atlanto-Odontoid Joint Replacement and Analysis of Its Biomechanical Properties. Turk Neurosurg. 2016;26(3):430-436. [18] McCahon RA, Evans DA, Kerslake RW, et al. Cadaveric study of movement of an unstable atlanto-axial (C1/C2) cervical segment during laryngoscopy and intubation using the Airtraq(®) , Macintosh and McCoy laryngoscopes. Anaesthesia. 2015;70(4):452-461.[19] Boszczyk BM, Littlewood AP, Putz R. A geometrical model of vertical translation and alar ligament tension in atlanto-axial rotation. Eur Spine J. 2012;21(8):1575-1579.[20] Schoenfeld AJ, Bono CM, Reichmann WM, et al. Type II odontoid fractures of the cervical spine: do treatment type and medical comorbidities affect mortality in elderly patients?Spine (Phila Pa 1976). 2011;36(11):879-885.[21] Takatori R, Tokunaga D, Hase H, et al. Three-dimensional morphology and kinematics of the craniovertebral junction in rheumatoid arthritis. Spine (Phila Pa 1976). 2010;35(23):E1278-E1284. [22] Lu B, He X, Zhao CG, et al. Biomechanical study of artificial atlanto-odontoid joint. Spine (Phila Pa 1976). 2009;34(18):1893-1899. [23] Pillai P, Baig MN, Karas CS, et al. Endoscopic image-guided transoral approach to the craniovertebral junction: an anatomic study comparing surgical exposure and surgical freedom obtained with the endoscope and the operating microscope. Neurosurgery. 2009;64(5 Suppl 2):437-442[24] Dmitriev AE, Lehman RA Jr, Helgeson MD, et al. Acute and long-term stability of atlantoaxial fixation methods: a biomechanical comparison of pars, pedicle, and intralaminar fixation in an intact and odontoid fracture model. Spine (Phila Pa 1976). 2009;34(4):365-370. [25] Kelly BP, Glaser JA, DiAngelo DJ. Biomechanical comparison of a novel C1 posterior locking plate with the harms technique in a C1-C2 fixation model. Spine (Phila Pa 1976). 2008;33(24):E920-E295. [26] Nishizawa S, Yamaguchi M, Matsuzawa Y. Interlaminar fixation using the atlantoaxial posterior fixation system (3XS system) for atlantoaxial instability: surgical results and biomechanical evaluation. Neurol Med Chir (Tokyo). 2004;44(2):61- 67.[27] Melcher RP, Puttlitz CM, Kleinstueck FS, et al. Biomechanical testing of posterior atlantoaxial fixation techniques. Spine (Phila Pa 1976). 2002;27(22):2435-2440.[28] Puttlitz CM, Goel VK, Clark CR, et al. Pathomechanisms of failures of the odontoid. Spine (Phila Pa 1976). 2000;25(22):2868-2876.[29] Puttlitz CM, Goel VK, Clark CR, et al. Biomechanical rationale for the pathology of rheumatoid arthritis in the craniovertebral junction. Spine (Phila Pa 1976). 2000; 25(13):1607-1616.[30] Wang M, Wang L, Li P, et al. A novel modelling and simulation method of hip joint surface contact stress. Bioengineered. 2016.[31] Dousteyssier B, Molimard J, Hamitouche C, et al. Patient dependent knee modeling at several flexion angles: a study on soft tissues loadings. Ann Phys Rehabil Med. 2016;59S:e32-e33. [32] Ayati BP, Kapitanov GI, Coleman MC, et al. Mathematics as a conduit for translational research in post-traumatic osteoarthritis. J Orthop Res. 2016.[33] Matsuyama K, Ishidou Y, Guo YM, et al. Finite element analysis of cementless femoral stems based on mid- and long-term radiological evaluation. BMC Musculoskelet Disord. 2016;17(1):397. [34] Stender ME, Regueiro RA, Ferguson VL. A poroelastic finite element model of the bone-cartilage unit to determine the effects of changes in permeability with osteoarthritis. Comput Methods Biomech Biomed Engin. 2016.[35] Bess S, Harris JE, Turner AW, et al. The effect of posterior polyester tethers on the biomechanics of proximal junctional kyphosis: a finite element analysis. J Neurosurg Spine. 2016.[36] Oba M, Inaba Y, Kobayashi N, et al. Effect of femoral canal shape on mechanical stress distribution and adaptive bone remodelling around a cementless tapered-wedge stem. Bone Joint Res. 2016;5(9): 362-369.[37] Yin L, Liao TC, Yang L, et al. Does Patella Tendon Tenodesis Improve Tibial Tubercle Distalization in Treating Patella Alta? A Computational Study. Clin Orthop Relat Res. 2016;474(11):2451-2461.[38] Hamid KS, Scott AT, Nwachukwu BU, et al. The Role of Fluid Dynamics in Distributing Ankle Stresses in Anatomic and Injured States. Foot Ankle Int. 2016,[39] Panagiotopoulou O, Rankin JW, Gatesy SM, et al. A preliminary case study of the effect of shoe-wearing on the biomechanics of a horse's foot. PeerJ. 2016;4: e2164.[40] McCarty CA, Thomason JJ, Gordon KD, et al. Finite-Element Analysis of Bone Stresses on Primary Impact in a Large-Animal Model: The Distal End of the Equine Third Metacarpal. PLoS One. 2016;11(7): e0159541.[41] Bruna-Rosso C, Arnoux PJ, Bianco RJ, et al. Finite Element Analysis of Sacroiliac Joint Fixation under Compression Loads. Int J Spine Surg. 2016;10:16. [42] Hejazi S, Rouhi G, Rasmussen J. The effects of gastrocnemius-soleus muscle forces on ankle biomechanics during triple arthrodesis. Comput Methods Biomech Biomed Engin. 2016.[43] Lee N, Ji GY, Yi S, et al. Finite Element Analysis of the Effect of Epidural Adhesions. Pain Physician. 2016; 19(5): E787-E793.[44] Naghibi Beidokhti H, Janssen D, et al. A comparison between dynamic implicit and explicit finite element simulations of the native knee joint. Med Eng Phys. 2016;38(10):1123-1130. [45] Lutz F, Mastel R, Runge M, et al. Calculation of muscle forces during normal gait under consideration of femoral bending moments. Med Eng Phys. 2016;38(9): 1008-1015. |

| [1] | Wu Liang-hao, Yu Bao-qing, Chen Fan-cheng. Supercapsular percutaneously-assisted total hip approach for the elderly with femoral neck fractures: study protocol for a prospective, open-label, randomized, controlled clinical trial [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1009-1014. |

| [2] | Chen Guang-dong, Cao Tong-jun, Li Jian. New bone fixation plate for the repair of avulsion fracture of the tibial attachment of the posterior cruciate ligament: study protocol for a prospective, open-label, self-controlled, clinical trial [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1020-1024. |

| [3] | Xie Qiang. Three-dimensional finite element model for biomechanical analysis of stress in knee inversion and external rotation after posterior cruciate ligament rupture [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1036-1040. |

| [4] | He Ze-dong, Zhao Jing, Chen Liang-yu, Li Ke, Weng Jie. Multilevel finite element analysis on the biological tribology damage of water on bone tissue [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1041-1045. |

| [5] | Li Jing, Yang Long, Wang Jian-ji, Liu Qin, Zou Qiang, Sun Yu, Ma Min-xian, Ye Chuan. Three-dimensional reconstruction based on DICOM data and its application for orthopedic implants [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1046-1051. |

| [6] | Li Hui, Ma Jun-yi, Ma Yuan, Zhu Xu . Establishment of a three-dimensional finite element model of ankylosing spondylitis kyphosis [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1069-1073. |

| [7] | Qin Di, Shang Yong-wei, Li Hui-jie, Han Yong-tai. Collapsed femoral head measured by X-ray and CT before hip replacement: study protocol for a single-center, open-label and diagnostic trial [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(7): 1080-1085. |

| [8] | Du Shi-yao, Zhou Feng-jin, Ni Bin, Chen Bo, Chen Jin-shui. Finite-element analysis of a novel posterior atlantoaxial restricted non-fusion fixation system [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(3): 383-389. |

| [9] | Zhang Li-chao, Zhang Li-min, Lv Yong-ming, Wang Zhi-hui, Yang Yang, Xu Fei, Dai Hai-feng, Li Jia, Cao Xiang-yu, Wu Li-zhu. Finite element analysis of knee flexion and extension movement [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(3): 396-400. |

| [10] | Jia Jin-ling, Dong Yu-zhen. Finite element analysis of prosthesis position during hip arthroplasty [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(3): 401-405. |

| [11] | Liu Fu-qian, Liang Wei-guo, Ye Dong-ping. Application and thinking of nucleus replacement, total disc replacement and posterior lumbar dynamic stabilization device for lumbar degenerative diseases [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(3): 440-444. |

| [12] | Wang Jing-xu, Gong Shu-yi, Wu Bo. Efficacy and safety of K-rod dynamic stabilization system in the repair of lumbar degenerative diseases: study protocol for a prospective, self-controlled, clinical trial [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(19): 2980-2985. |

| [13] | Zhou Gang, Zhang Yu-kun, Huang Wei-min. Risk factors for ligamentum flavum hypertrophy in lumbar spinal stenosis patients from the Xinjiang Uygur Autonomous Region, China: protocol for a retrospective, single-center study [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(19): 2993-2998. |

| [14] | Ma Yong, Sikandaer•Siyiti, Ou Yong, Aikeremujiang•Muheremu, Ma Yuan. Finite element analysis of kyphosis in ankylosing spondylitis treated by different osteotomy methods [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(19): 3038-3043. |

| [15] | Li Xin, Tang Jing, Li Ze-kui, Li Hong-fa, Liang Meng, Zhang Juan. Age-related changes in condyle evaluated by cone-beam CT reconstruction [J]. Chinese Journal of Tissue Engineering Research, 2017, 21(19): 3044-3055. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||