[1] SUN JL, FENG Y, SHI ZZ, et al. Biodegradable Zn-0.5Li alloy rib plate: Processing procedure development and in vitro performance evaluation. J Mater Sci Technol. 2023;141:245-256.

[2] SONG Y, WU H, GAO Y, et al. Zinc Silicate/Nano-Hydroxyapatite/Collagen Scaffolds Promote Angiogenesis and Bone Regeneration via the p38 MAPK Pathway in Activated Monocytes. ACS Appl Mater Inter. 2020;12(14):16058-16075.

[3] CEYLAN M N, AKDAS S, YAZIHAN N. Is Zinc an Important Trace Element on Bone-Related Diseases and Complications? A Meta-analysis and Systematic Review from Serum Level, Dietary Intake, and Supplementation Aspects. Biol Trace Elem Res. 2021; 199(2):535-549.

[4] VOJTĚCH D, KUBÁSEK J, ŠERÁK J, et al. Mechanical and corrosion properties of newly developed biodegradable Zn-based alloys for bone fixation. Acta Biomater. 2011;7(9):3515-3522.

[5] YANG H, JIA B, ZHANG Z, et al. Alloying design of biodegradable zinc as promising bone implants for load-bearing applications. Nat Commun. 2020;11(1):401.

[6] QIN Y, LIU A, GUO H, et al. Additive manufacturing of Zn-Mg alloy porous scaffolds with enhanced osseointegration: In vitro and in vivo studies. Acta Biomater. 2022;145:403-415.

[7] GARCIA-MINTEGUI C, CORDOBA LC, BUXADERA-PALOMERO J, et al. Zn-Mg and Zn-Cu alloys for stenting applications: From nanoscale mechanical characterization to in vitro degradation and biocompatibility. Bioact Mater. 2021;6(12):4430-4446.

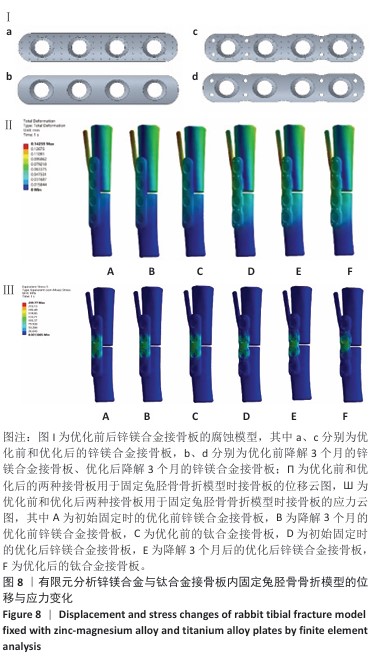

[8] DIAA AA, EL-MAHALLAWY N, SHOEIB M, et al. Biodegradable PMMA coated Zn-Mg alloy with bimodal grain structure for orthopedic applications - A promising alternative. Bioact Mater. 2024;39:479-491.

[9] WANG Z, WANG W, ZHANG X, et al. Modulation of Osteogenesis and Angiogenesis Activities Based on Ionic Release from Zn-Mg Alloys. Materials (Basel). 2022;15(20):7117.

[10] BIHARI A, GEE A, BOUGHERARA H, et al. Cytotoxicity of novel hybrid composite materials for making bone fracture plates. Biomed Mater. 2024;19(4):041001.

[11] ZHENG Y, LIU X, SHEN D, et al. Perceiving the connection between the bone healing process and biodegradation of biodegradable metal implants through precise bioadaptability principle. J Mater Sci Technol. 2023;147:132-144.

[12] ZDERO R, BRZOZOWSKI P, SCHEMITSCH EH, et al. Biomechanical Design Optimization of Distal Humerus Fracture Plates: A Review. BioMed Res Int. 2024;2024(1):1-14.

[13] YANG X, DONG J, YANG J, et al. Similar Material Proportioning Tests and Mechanical Properties Based on Orthogonal Design. Materials. 2023;16(19):6439.

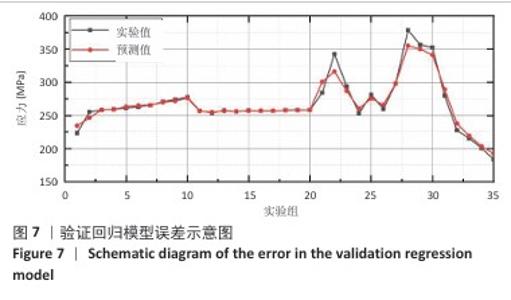

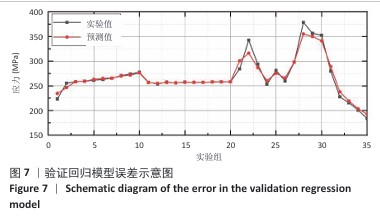

[14] FANG R, JI A, ZHAO Z, et al. A regression orthogonal biomechanical analysis of internal fixation for femoral shaft fracture. Biocybern Biomed Eng. 2020;40(3):1277-1290.

[15] 龙登燕,纪爱敏,赵仲航,等.基于正交试验接骨螺钉参数的生物相容性评价[J].中国组织工程研究,2020,24(10):1574-1579.

[16] BROUWER DE KONING SG, DE WINTER N, MOOSABEIKI V, et al. Design considerations for patient-specific bone fixation plates: a literature review . Med Biol Eng Comput. 2023;61(12):3233-3252.

[17] 陈俞鹏,王海波,薛朝军,等.工业装配抗振外骨骼的动力学仿真及试验研究[J].中国机械工程,2023,34(4):404-413.

[18] ZHOU K, YANG H. Effects of Bone-Plate Material on the Predicted Stresses in the Tibial Shaft Comminuted Fractures: A Finite Element Analysis. J Invest Surg. 2022;35(1):132-140.

[19] PRADEEP RAJA C, KARTHIK BABU NB, RAJESH KANNAN A, et al.

Progress in the Optimization of Compositional Design and Thermomechanical Processing of Metastable beta Ti Alloys for Biomedical Applications. ACS Biomater Sci Eng. 2024;10(6): 3528-3547.

[20] WANG F, LIU Y, HUO Y, et al. Biomechanical study of internal fixation methods for femoral neck fractures based on Pauwels angle. Front Bioeng Biotech. 2023;11:1143575.

[21] PAREATUMBEE P, ZAINUL-ABIDIN S, YEW A, et al. Effect of implant length variations on stress shielding in proximal humeral replacement after tumor excision under torsion: Finite element study. J Orthop Res. 2023;41(6):1139-1147.

[22] WANG Y. Bioadaptability: An Innovative Concept for Biomaterials. J Mater Sci Technol. 2016;32(9): 801-809.

[23] CHEN PH, CHEN CY, LIN KC, et al. Fixing Cho Type IIC Distal Clavicle Fractures with Hook Plates Leads to a High Incidence of Subacromial Osteolysis: A Retrospective Study and Literature Review. Clin Orthop Surg. 2024;16(5):694-701.

[24] HU J, SZYMCZAK S. A review on longitudinal data analysis with random forest. Brief Bioinform. 2023;24(2):1-11.

[25] LEWIS GS, MISCHLER D, WEE H, et al. Finite Element Analysis of Fracture Fixation. Curr Osteoporos Rep. 2021;19(4):403-416.

[26] WEE H, REID JS, CHINCHILLI VM, et al. Finite Element-Derived Surrogate Models of Locked Plate Fracture Fixation Biomechanics. Ann Biomed Eng. 2016;45(3):668-680.

[27] ZHANG Q, CHEN Z, PENG Y, et al. The novel magnesium–titanium hybrid cannulated screws for the treatment of vertical femoral neck fractures: Biomechanical evaluation. J Orthop Translat. 2023;42:

127-136.

[28] NASR AZADANI M, ZAHEDI A, BOWOTO OK, et al. A review of current challenges and prospects of magnesium and its alloy for bone implant applications. Prog Biomater. 2022;11(1):1-26.

[29] LI J, QIN L, YANG K, et al. Materials evolution of bone plates for internal fixation of bone fractures: A review. J Mater Sci Technol. 2020;36: 190-208.

[30] QI T, WENG J, YU F, et al. Insights into the Role of Magnesium Ions in Affecting Osteogenic Differentiation of Mesenchymal Stem Cells. Biol Trace Elem Res. 2020;199(2):559-567.

[31] FAZZALARI NL. Bone fracture and bone fracture repair. Osteoporos Int. 2011;22(6):2003-2006.

[32] VAUTRIN A, WESSELING M, WIRIX-SPEETJENS R, et al. Time-dependent in silico modelling of orthognathic surgery to support the design of biodegradable bone plates. J Mech Behav Biomed Mater. 2021;121:104641. |