[1] DU F, ZHOU J. Vascular Intervention: From Angioplasty to Bioresorbable Vascular Scaffold. Adv Exp Med Biol. 2018;1097:181-189.

[2] FORRESTAL B, CASE BC, YERASI C, et al. Bioresorbable Scaffolds: Current Technology and Future Perspectives. Rambam Maimonides Med J. 2020;11(2):e0016.

[3] POLIMENI A, SORRENTINO S, SPACCAROTELLA C, et al. Stent Thrombosis After Percutaneous Coronary Intervention: From Bare-Metal to the Last Generation of Drug-Eluting Stents. Interv Cardiol Clin. 2022;11(4):465-473.

[4] 彭坤,李婧,王斯睿,等.可降解血管支架结构设计及优化的研究进展[J].中国生物医学工程学报,2019,38(3):367-374.

[5] WANG Y, WU H, ZHEN W, et al. [Research Progress of Biodegradable Vascular Stent]. Zhongguo Yi Liao Qi Xie Za Zhi. 2021;45(4):410-415.

[6] SHEN Y, YU X, CUI J, et al. Development of Biodegradable Polymeric Stents for the Treatment of Cardiovascular Diseases. Biomolecules. 2022;12(9):1245.

[7] 尹林,黄华,袁广银,等.可降解镁合金临床应用的最新研究进展[J].中国材料进展,2019,38(2):126-137.

[8] GĄSIOR G, SZCZEPAŃSKI J, RADTKE A. Biodegradable Iron-Based Materials-What Was Done and What More Can Be Done? Materials (Basel). 2021;14(12):3381.

[9] ZHANG X, GUO Z, ZHU L, et al. Challenges and chances coexist: A visualized analysis and bibliometric study of research on bioresorbable vascular scaffolds from 2000 to 2022. Medicine (Baltimore). 2023; 102(21):e33885.

[10] KHALAJ R, TABRIZ AG, OKEREKE MI, et al. 3D printing advances in the development of stents. Int J Pharm. 2021;609:121153.

[11] SONG Y, LI B, CHEN H, et al. Research progress of absorbable stents. Int J Med Sci. 2024;21(2):404-412.

[12] ZHAO Y, CUI H. Finite element analysis of braided dense-mesh stents for carotid artery stenosis. Comput Methods Biomech Biomed Engin. 2024;27(5):609-619.

[13] MOERI L, LICHTENBERG M, GNANAPIRAGASAM S, et al. Braided or laser-cut self-expanding nitinol stents for the common femoral vein in patients with post-thrombotic syndrome. J Vasc Surg Venous Lymphat Disord. 2021;9(3):760-769.

[14] MACTAGGART J, POULSON W, SEAS A, et al. Stent Design Affects Femoropopliteal Artery Deformation. Ann Surg. 2019;270(1):180-187.

[15] KOREI N, SOLOUK A, NAZARPAK MH, et al. A review on design characteristics and fabrication methods of metallic cardiovascular stents. Mater Today Commun. 2022;31:103467.

[16] 申祥,王炎,孙鹏,等.新型球扩式锥形血管支架的径向支撑力学行为[J].医用生物力学,2023,38(3):487-492.

[17] LIU Q, LIU M, TIAN Y, et al. Evaluation of resistance to radial cyclic loads of poly(L-lactic acid) braided stents with different braiding angles. Int J Biol Macromol. 2022;218:94-101.

[18] UBACHS R, VAN DER SLUIS O, SMITH S, et al. Computational modeling of braided venous stents - Effect of design features and device-tissue interaction on stent performance. J Mech Behav Biomed Mater. 2023; 142:105857.

[19] ALIZADEH M, AGHAJANI KOOPAIE A, SHAKERI JOUSHEGHAN S. Investigation of changing geometry parameters of nickel-titanium shape memory alloys wire stent in cardiovascular implants. Comput Methods Biomech Biomed Engin. 2023;26(8):952-959.

[20] WANG B, LIU M, LIU J, et al. Key Factors of Mechanical Strength and Toughness in Oriented Poly(l-lactic acid) Monofilaments for a Bioresorbable Self-Expanding Stent. Langmuir. 2022;38(44): 13477-13487.

[21] LIU J, WANG B, LIU W, et al. Regulating mechanical performance of poly (l-lactide acid) stent by the combined effects of heat and aqueous media. Int J Biol Macromol. 2023;242(Pt 4):124987.

[22] ZHAO G, LIU M, DENG D, et al. Effects of constraint between filaments on the radial compression properties of poly (l-lactic acid) self-expandable braided stents. Polym Test. 2021;93:106963.

[23] MCKENNA CG, VAUGHAN TJ. A finite element investigation on design parameters of bare and polymer-covered self-expanding wire braided stents. J Mech Behav Biomed Mater. 2021;115:104305.

[24] SUN J, SUN K, BAI K, et al. A novel braided biodegradable stent for use in congenital heart disease: Short-term results in porcine iliac artery. J Biomed Mater Res A. 2019;107(8):1667-1677.

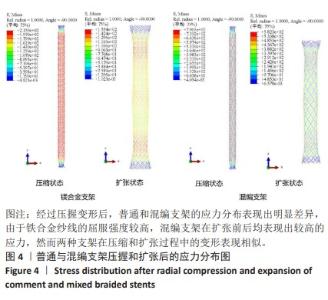

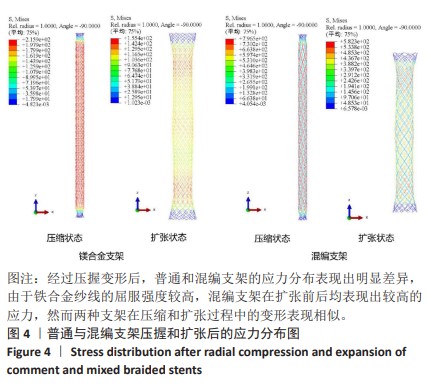

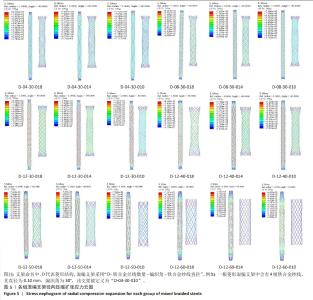

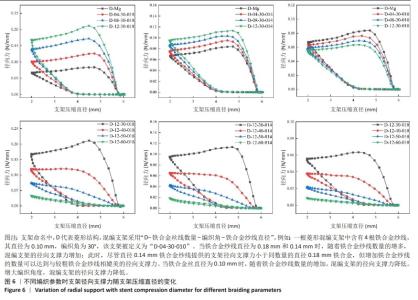

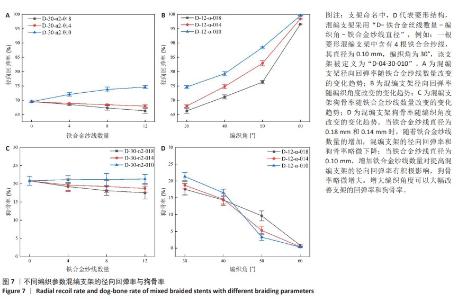

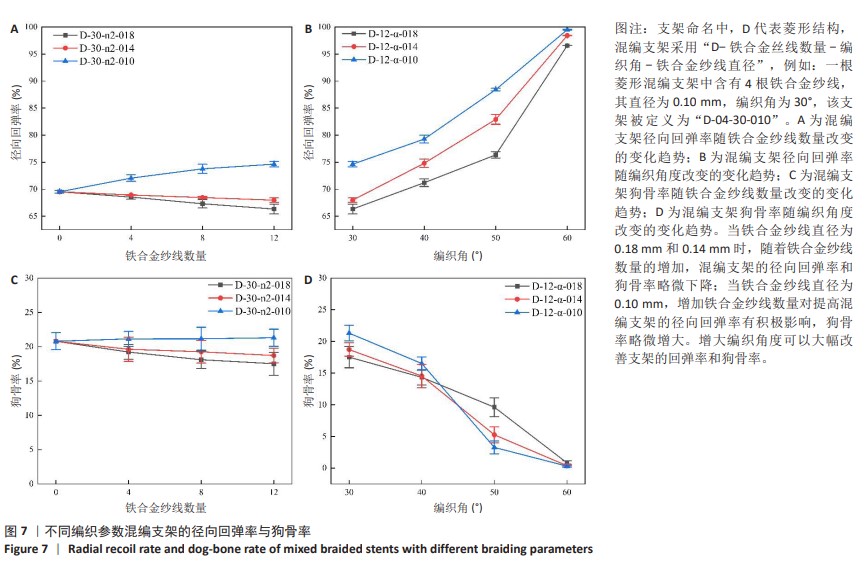

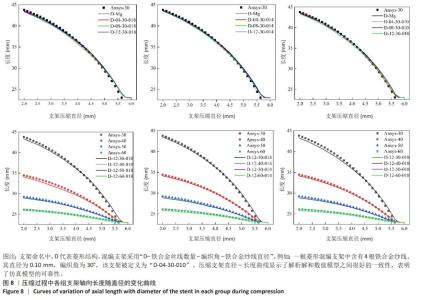

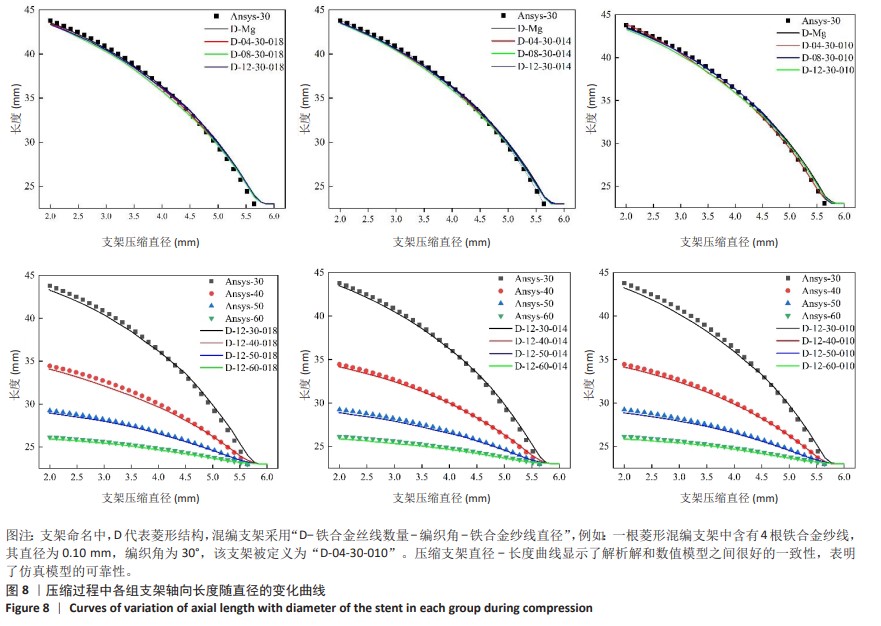

[25] LIU M, TIAN Y, CHENG J, et al. Mixed-braided stent: An effective way to improve comprehensive mechanical properties of poly (L-lactic acid) self-expandable braided stent. J Mech Behav Biomed Mater. 2022; 128:105123.

[26] 薛雯.复合编织血管支架物理力学性能研究[D].上海:东华大学, 2019.

[27] HAN CM, LIH E, CHOI SK, et al. Biodegradable sheath-core biphasic monofilament braided stent for bio-functional treatment of esophageal strictures. J Ind Eng Chem. 2018;67:396-406.

[28] 谭志刚,周倩,蒋宇钢.生物可降解镁合金血管支架:缺点及未来研究趋势[J].中国组织工程研究,2015,19(8):1284-1288.

[29] 董士武,周岚曦,邵路,等.镁合金生物材料降解对内皮化细胞的影响[J].中国组织工程研究,2023,27(21):3398-3406.

[30] 许雅南,王伟强,杨帅康,等.铁基材料在生物可降解血管支架领域的研究进展[J].钢铁钒钛,2023,44(4):158-166.

[31] NGUYEN DT, SMITH AF, JIMÉNEZ JM. Stent strut streamlining and thickness reduction promote endothelialization. J R Soc Interface. 2021;18(181):20210023.

[32] 林文娇.铁基血管支架制备及其生物降解机理研究[D].哈尔滨:哈尔滨工程大学,2021.

[33] 赵帆.双重可控式编织自增强型可降解血管支架的设计制备及构效关系[D].上海:东华大学,2019.

[34] 付文宇,李立新,乔爱科.编织支架弯曲变形时扁平现象的数值模拟研究[J].北京生物医学工程,2020,39(5):455-461.

[35] PAN C, ZENG X, HAN Y, et al. Investigation of braided stents in curved vessels in terms of “Dogbone” deformation. Math Biosci Eng. 2022; 19(6):5717-5737.

[36] KIM JH, CHOI JY, YOON HY. Evaluation of mechanical properties of self-expanding metal stents for optimization of tracheal collapse in dogs. Can J Vet Res. 2022;86(3):188-193.

[37] CARBONARO D, LUCCHETTI A, AUDENINO AL, et al. Multi-objective design optimization of bioresorbable braided stents. Comput Methods Programs Biomed. 2023;242:107781.

[38] PAN C, HAN Y, LU J. Structural Design of Vascular Stents: A Review. Micromachines (Basel). 2021;12(7):770.

[39] JEDWAB MR, CLERC CO. A study of the geometrical and mechanical properties of a self-expanding metallic stent--theory and experiment. J Appl Biomater. 1993;4(1):77-85.

[40] WANG WQ, LIANG DK, YANG DZ, et al. Analysis of the transient expansion behavior and design optimization of coronary stents by finite element method. J Biomech. 2006;39(1):21-32.

[41] SHEN Y, YU X, CUI J, et al. Development of Biodegradable Polymeric Stents for the Treatment of Cardiovascular Diseases. Biomolecules. 2022;12(9):1245.

|