[1] NIINOMI M, NAKAI M. Titanium-based biomaterials for preventing stress shielding between implant devices and bone. Int J Biomater. 2011;2011:836587.

[2] 王良涛,李珊,陆豆豆,等.基于正交试验梯度多孔牙种植体结构的设计研究[J].华西口腔医学杂志,2023,41(6):647-652.

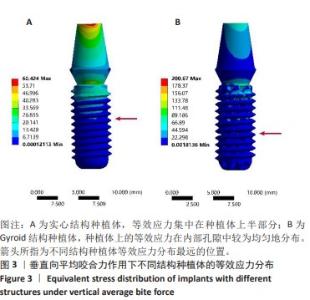

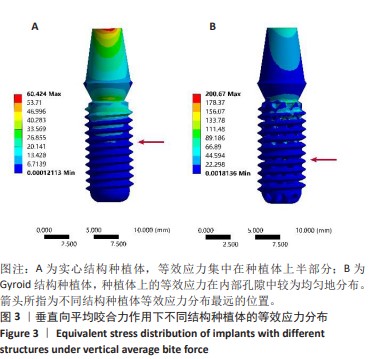

[3] 张玲,李凯,潘庆,等.仿真“骨小梁”牙种植体的生物力学特征[J].中国组织工程研究,2017,21(26):4137-4142.

[4] 孙亚迪,马剑雄,王岩,等.三周期极小曲面骨支架微观结构对支架性能的影响研究进展[J].中国修复重建外科杂志,2023,37(10): 1314-1318.

[5] PUGLIESE R, GRAZIOSI S. Biomimetic scaffolds using triply periodic minimal surface-based porous structures for biomedical applications. SLAS Technol. 2023;28(3):165-182.

[6] MA S, TANG Q, HAN X, et al. Manufacturability, mechanical properties, mass-transport properties and biocompatibility of triply periodic minimal surface (TPMS) porous scaffolds fabricated by selective laser melting. Mater Des. 2020;195:109034.

[7] MAEVSKAIA E, GUERRERO J, GHAYOR C, et al. Triply periodic minimal surface-based scaffolds for bone tissue engineering: a mechanical, in vitro and in vivo study. Tissue Eng Part A. 2023;29(19-20):507-517.

[8] YÁNEZ A, CUADRADO A, MARTEL O, et al. Gyroid porous titanium structures: a versatile solution to be used as scaffolds in bone defect reconstruction. Mater Des. 2018;140:21-29.

[9] MIRZAALI MJ, MOOSABEIKI V, RAJAAI SM, et al. Additive manufacturing of biomaterials—design principles and their implementation. Materials. 2022;15(15):5457.

[10] WU J, ZHANG Y, LYU Y, et al. On the various numerical techniques for the optimization of bone scaffold. Materials. 2023;16(3):974.

[11] BANDYOPADHYAY A, MITRA I, AVILA JD, et al. Porous metal implants: processing, properties, and challenges. Int J Extreme Manuf. 2023; 5(3):32014.

[12] SHENG X, WANG A, WANG Z, et al. Advanced surface modification for 3D-printed titanium alloy implant interface functionalization. Front Bioeng Biotechnol. 2022;10:850110.

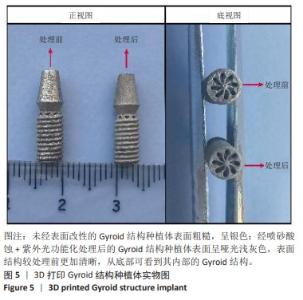

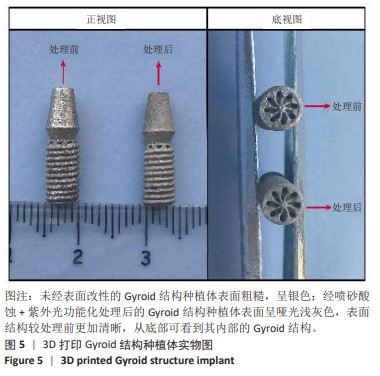

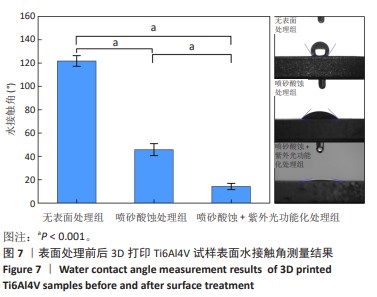

[13] YIN C, ZHANG T, WEI Q, et al. Surface treatment of 3D printed porous Ti6Al4V implants by ultraviolet Photofunctionalization for improved osseointegration. Bioact Mater. 2022;7:26-38.

[14] 孔亮,刘宝林,胡开进,等.螺纹种植体螺距的优化设计和应力分析[J].华西口腔医学杂志,2006(6):509-512+515.

[15] 李昕茹,赵文博,纪妍,等.不同螺纹种植体修复下颌第一磨牙即刻负荷的初始稳定性比较[J].中国组织工程研究,2024,28(22): 3445-3450.

[16] 吕虹雨,孙毅,李天佑,等.有限元分析不同材料对超短种植体的影响[J].口腔医学,2023,43(4):308-311,333.

[17] 周钰琳,毛志红,王琼瑶,等.牙科即刻种植中不同螺纹形态及深度设计参数种植体的生物力学性能[J].医用生物力学,2020,35(1): 95-100.

[18] PACHA-OLIVENZA MA, GALLARDO-MORENO AM, MÉNDEZ-VILAS A,

et al. Effect of UV irradiation on the surface gibbs energy of Ti6Al4V and thermally oxidized Ti6Al4V. J Colloid Interface Sci. 2008;320(1):

117-124.

[19] CHMIELEWSKA A, DEAN D. The role of stiffness-matching in avoiding stress shielding-induced bone loss and stress concentration-induced skeletal reconstruction device failure. Acta Biomater. 2024;173:51-65.

[20] RAFFA M L, NGUYEN V, HERNIGOU P, et al. Stress shielding at the bone-implant interface: influence of surface roughness and of the bone‐implant contact ratio. J Orthop Res. 2021;39(6):1174-1183.

[21] ZHANG C, ZENG C, WANG Z, et al. Optimization of stress distribution of bone-implant interface (BII). Biomater Adv. 2023;147:213342.

[22] 黄道宇.基于3D打印技术的多孔牙种植体制备及性能研究[D]. 上海:上海应用技术大学,2022.

[23] ZHU LY, LI L, SHI JP, et al. Mechanical characterization of 3D printed multi-morphology porous Ti6Al4V scaffolds based on triply periodic minimal surface architectures . Am J Transl Res. 2018;10(11): 3443-3454.

[24] WANG Z, LIAO B, LIU Y, et al. Influence of structural parameters of 3D‐printed triply periodic minimal surface gyroid porous scaffolds on compression performance, cell response, and bone regeneration. J Biomed Mater Res Part B. 2024;112(1):e35337.

[25] HAYASHI K, KISHIDA R, TSUCHIYA A, et al. Superiority of triply periodic minimal surface gyroid structure to strut-based grid structure in both strength and bone regeneration. ACS Appl Mater Interfaces. 2023; 15(29):34570-34577.

[26] 徐伟.基于SLM梯度多孔钛口腔种植体结构设计及应用基础研究[D].北京:北京科技大学,2021.

[27] FROST HM. A 2003 update of bone physiology and wolff’s law for clinicians. Angle Orthod. 2004;74(1):3-15.

[28] PENG WM, LIU YF, JIANG XF, et al. Bionic mechanical design and 3D printing of novel porous Ti6Al4V implants for biomedical applications. J Zhejiang Univ Sci B. 2019;20(8):647-659.

[29] LEE U L, YUN S, LEE H, et al. Osseointegration of 3D-printed titanium implants with surface and structure modifications. Dent Mater. 2022; 38(10):1648-1660.

[30] ZHANG J, LIU J, WANG C, et al. A comparative study of the osteogenic performance between the hierarchical micro/submicro-textured 3D-printed Ti6Al4V surface and the SLA surface. Bioact Mater. 2020; 5(1):9-16.

[31] TOOSI S, JAVID-NADERI M J, TAMAYOL A, et al. Additively manufactured porous scaffolds by design for treatment of bone defects. Front Bioeng Biotechnol. 2024;11:1252636.

[32] 赖春花,徐淑兰,许言,等.颌骨不同骨质区域对种植体表面的接触成骨的影响[J].实用医学杂志,2021,37(8):1008-1013.

[33] 高岩,林曦,刘影.碱热处理纯钛表面纳米改性后对成骨细胞早期黏附生长的影响[J].中国组织工程研究,2024,28(15):2302-2306.

[34] SARTORETTO SC, ALVES ATNN, RESENDE RFB, et al. Early osseointegration driven by the surface chemistry and wettability of dental implants. J Appl Oral Sci. 2015;23(3):279-287.

[35] SHU T, WANG X, LI M, et al. Nanoscaled titanium oxide layer provokes quick osseointegration on 3D-printed dental implants: a domino effect induced by hydrophilic surface. ACS Nano. 2024;18(1):783-797.

[36] WALL I, DONOS N, CARLQVIST K, et al. Modified titanium surfaces promote accelerated osteogenic differentiation of mesenchymal stromal cells in vitro. Bone. 2009;45(1):17-26.

[37] PINTO GDCS, REIS I ARD, LEOCÁDIO ADCS, et al. Evaluation of hydrophilic surface osseointegration in low-density bone: preclinical study in rabbits. Braz Dent J. 2023;34(3):66-72.

[38] SÁNCHEZ-PUETATE JC, SILVA BLG, PINOTTI FE, et al. Assessing bone formation on hydrophilic and hydrophobic implant surfaces in a murine model treated with bisphosphonates. Clin Oral Invest. 2024;28(1):89.

[39] DONOHOE E, KAHATAB R, BARRAK F. A systematic review comparing the macrophage inflammatory response to hydrophobic and hydrophilic sandblasted large grit, acid‐etched titanium or titanium–zirconium surfaces during in vitro studies. Clin Exp Dent Res. 2023;9(3):437-448.

[40] SHAO H, MA M, WANG Q, et al. Advances in the superhydrophilicity-modified titanium surfaces with antibacterial and pro-osteogenesis properties: a review. Front Bioeng Biotechnol. 2022;10:1000401.

[41] CHU X, WU F, LIU Z, et al. Brush polymer coatings with hydrophilic main-chains for improving surface antibacterial properties. ACS Macro Lett. 2023;12(4):428-432.

[42] WEN Y, DONG H, LIN J, et al. Response of human gingival fibroblasts and porphyromonas gingivalis to UVC-activated titanium surfaces. J Funct Biomater. 2023;14(3):137.

[43] 张华英,赵雨薇,于海洋.椅旁紫外线光功能化技术提高钛种植体生物活性的研究进展[J].口腔疾病防治,2022,30(4):295-299.

[44] TANIYAMA T, SARUTA J, MOHAMMADZADEH REZAEI N, et al. UV-photofunctionalization of titanium promotes mechanical anchorage in a rat osteoporosis model. Int J Mol Sci. 2020;21(4):1235.

[45] HAYASHI M, JIMBO R, XUE Y, et al. Photocatalytically induced hydrophilicity influences bone remodelling at longer healing periods: a rabbit study. Clin Oral Implan Res. 2014;25(6):749-754.

[46] HIROTA M, OZAWA T, IWAI T, et al. UV-mediated photofunctionalization of dental implant: a seven-year results of a prospective study. J Clin Med. 2020;9(9):2733.

[47] MINAMIKAWA H, IKEDA T, ATT W, et al. Photofunctionalization increases the bioactivity and osteoconductivity of the titanium alloy Ti6Al4V. J Biomed Mater Res Part A. 2014;102(10):3618-3630.

[48] 秦风利,王超,刘婷,等.3D打印多孔钛个性化根形种植体的体内骨愈合研究[J].口腔医学研究,2018,34(12):1337-1341. |