Chinese Journal of Tissue Engineering Research ›› 2024, Vol. 28 ›› Issue (29): 4691-4696.doi: 10.12307/2024.582

Previous Articles Next Articles

Polyetheretherketone and its composite materials in post core crown restoration: problems and clinical application value

Liu Yang1, Cao Youhui1, Bao Xuemei2

- 1School of Stomatology, Inner Mongolia Medical University, Hohhot 010059, Inner Mongolia Autonomous Region, China; 2Inner Mongolia Medical University Affiliated Hospital, Hohhot 010050, Inner Mongolia Autonomous Region, China

-

Received:2023-10-12Accepted:2023-12-14Online:2024-10-18Published:2024-03-23 -

Contact:Bao Xuemei, Master, Chief physician, Inner Mongolia Medical University Affiliated Hospital, Hohhot 010050, Inner Mongolia Autonomous Region, China -

About author:Liu Yang, Master candidate, School of Stomatology, Inner Mongolia Medical University, Hohhot 010059, Inner Mongolia Autonomous Region, China

CLC Number:

Cite this article

Liu Yang, Cao Youhui, Bao Xuemei. Polyetheretherketone and its composite materials in post core crown restoration: problems and clinical application value[J]. Chinese Journal of Tissue Engineering Research, 2024, 28(29): 4691-4696.

share this article

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

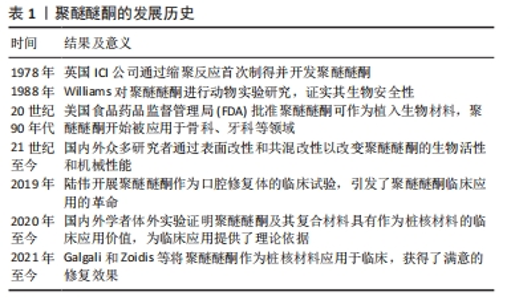

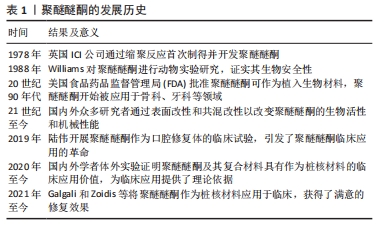

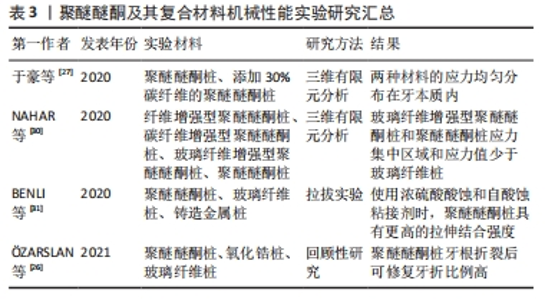

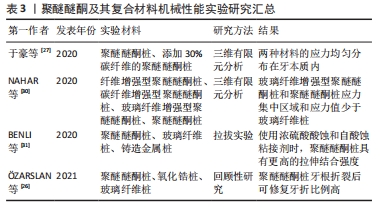

2.2 醚醚酮及其复合材料的简述 聚醚醚酮是半晶型芳香族高性能特级工程塑料聚合物,由4,4’-二氟二苯甲酮与对苯二酚投入二苯砜溶剂中在碱金属碳酸盐作用下进行缩聚反应制得。自1978年首次开发以来,聚醚醚酮被广泛用于国防军工、汽车、轮船、航空航天、石油化工、精密仪器制造等领域[16]。由于聚醚醚酮优异的高性能热塑性,20世纪90年代主要被应用于整形和骨科[17]。 聚醚醚酮的化学结构易与玻璃离子、碳纤维等增强剂共混、复合[18],以聚醚醚酮材料为基质,通过压膜注塑和熔融共混技术添加不同种类比例的填料形成新型复合材料[19],如玻璃纤维加强聚醚醚酮、碳纤维加强聚醚醚酮、羟基磷灰石加强聚醚醚酮、氟磷灰石加强型聚醚醚酮等,填料和聚醚醚酮的界面能够有效传递应力,防止裂纹扩展,并且填料与聚醚醚酮反应形成官能团[19],改变复合材料的弹性模量、强度、摩擦,在一定程度上提高聚醚醚酮的机械性能,从而扩展了聚醚醚酮的应用范围。聚醚醚酮及其复合材料的加工性能好、高温下流动性佳、弹性佳、密度低(1 300 kg/cm3)[21]、强度高、易加工成型[20],用于可摘局部义齿支架可减少基牙应力,减缓牙槽骨的吸收[22];聚醚醚酮正畸弓丝比镍钛弓丝具有更高的断裂强度,可用于托槽结扎的弓丝[23];聚醚醚酮作为种植体和愈合基台较传统钛合金材料具有更佳的细胞活性[24]。 2.3 聚醚醚酮的机械性能 在过度负荷下桩核修复的根管治疗牙易发生牙折。根据牙折部位的不同分为可修复牙折与不可修复牙折,当牙折发生在牙颈部冠方时称为可修复牙折,当牙折涉及到牙颈部根方时称为不可修复牙折[25]。研究表明,铸造镍铬合金桩修复时可修复牙折比例为11.1%,纤维桩修复时可修复牙折比例可达95%,无论剩余侧壁数目为多少,纤维桩修复折裂后可修复牙折的比例均高于铸造金属组[1]。有学者通过体外实验比较聚醚醚酮桩、氧化锆桩、玻璃纤维桩修复上颌中切牙的牙折方式,发现聚醚醚酮桩牙根折裂后可修复比例高于氧化锆桩和玻璃纤维桩[26]。于豪等[27]研究表明,聚醚醚酮及添加30%碳纤维的聚醚醚酮桩将应力均匀分布在牙本质内,最大应力分布在牙颈部冠方。对此,可认为聚醚醚酮及其复合材料作桩核修复时,在过度负荷下牙根折断时以可修复失效为主。同时也有学者经过实验证明,聚醚醚酮无论是个性化桩核还是预成桩都能为患牙二次修复提供可能[28]。 纯聚醚醚酮的弹性模量为3.0-4.0 GPa[29],经过碳纤维加强的聚醚醚酮弹性模量达到18.0 GPa[30],更接近牙本质的弹性模量。有研究通过建立上颌中切牙的有限元模型,比较氧化锆桩核、纯钛桩核、含30%碳纤维聚醚醚酮桩核的应力情况,发现碳纤维增强型聚醚醚酮桩在牙本质中产生的应力更小,可以提高桩核修复的成功率,碳纤维增强型复合材料桩可成为纤维桩的替代材料[29]。聚醚醚酮的拉伸强度约80 GPa[29],弯曲强度为170 MPa(牙本质的弯曲强度为212.9 MPa[28]),碳纤维增强后聚醚醚酮的弯曲强度可达到 644.28 MPa,冲击强度可达到 142.63 kJ/m2[19]。NAHAR等[30]通过三维有限元分析得出玻璃纤维增强型聚醚醚酮桩和聚醚醚酮桩的应力分布相似,并且应力值和应力集中区域均小于玻璃纤维桩,根管内的应力分布良好,桩核折裂发生率更低,认为玻璃纤维增强型聚醚醚酮桩核和聚醚醚酮桩核可以替代玻璃纤维和铸造金属桩。体外研究证明经过浓硫酸酸蚀和使用自酸蚀粘接剂时,聚醚醚酮桩比金属和玻璃纤维桩具有更高的拉伸结合强度(14.33 MPa)[31] 。周哲[19]的实验结果显示,60%连续碳纤维增强聚醚醚酮的弯曲强度约为644.28 MPa,与纯钛弯曲强度相似,但弹性模量为纯钛的一半。另外,赵婷[21]的实验证明,质量分数50%玻璃纤维增强聚醚醚酮的弹性模量(17.4 GPa)与牙本质弹性模量接近。不同材料的弹性模量见表2。聚醚醚酮及其复合材料的机械性能实验研究见表3。"

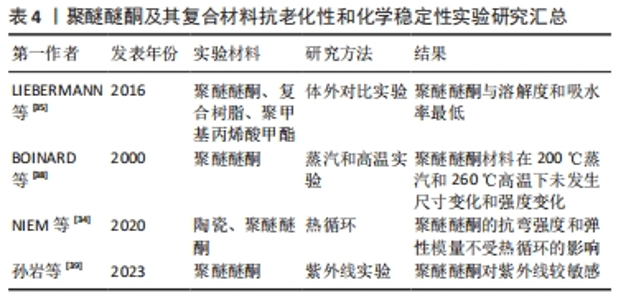

聚醚醚酮的机械性能受聚合反应时间的影响。庞馨蕾等[32]采用亲核取代法,以二苯砜为溶剂合成聚醚醚酮并比较不同聚合反应时间(3.0-5.0 h)对材料性能的影响,发现当聚合时间为3 h和3.5 h时,聚醚醚酮的溶体黏度低,加工性能差,注塑后的试样在模具中断裂;当聚合时间为4 h时,材料的拉伸强度为99.8 MPa,断裂伸长率为4.5%;当聚合时间为5 h时,材料的拉伸强度不变为99.8 MPa,断裂伸长率为32.7%,力学性能最佳,具有高刚度和高韧性。 2.4 聚醚醚酮的抗老化性和化学稳定性 老化是高分子材料不可避免的现象,在加工、贮存和使用过程中受到化学、生物、物理等因素的影响,导致材料的性能下降和强度失效。由于聚醚醚酮的低水溶性,在浸水情况下没有出现抗弯强度下降的现象[33]。NIEM等[34]评估了热循环对陶瓷、聚醚醚酮机械性能的影响,发现聚醚醚酮的抗弯强度和弹性模量不受热循环的影响。另有学者证明在生理唾液、人工唾液、生理盐水、蒸馏水4种液体环境中,在环境温度1 ℃下分别放置7,14,28,90,180 d,与复合树脂、聚甲基丙烯酸甲酯材料相比,聚醚醚酮的溶解度和吸水率最低[35]。但是聚醚醚酮老化后与机械性能之间的关系未得到证明[36]。 聚醚醚酮的化学性能稳定,除与98%浓硫酸溶液发生磺化反应外,与其他化学药品不会发生化学反应[37]。另外,聚醚醚酮的水溶解度为0.5%,即使长期暴露在高温高湿环境中的化学性能依然稳定。BOINARD等[38]的实验证明,聚醚醚酮材料在200 ℃蒸汽和260 ℃高温下未发生尺寸变化和强度变化。有实验显示聚醚醚酮对紫外线较敏感,随着紫外线照射时间的增加,聚醚醚酮材料表面变黄、出现鼓包裂纹、表层分解现象,但是短时间内的机械性能、热稳定性没有明显变化[39]。 聚醚醚酮具有很强的热稳定性,熔化温度为345 ℃,玻璃化转变温度可达143 ℃,在200 ℃下的抗弯强度达24 MPa,250 ℃下的抗弯强度达13.0-14.0 MPa,并且在250 ℃依然保持较高的耐磨性和低摩擦系数。当温度达到900 ℃时,聚醚醚酮的残余含量仍大于40%[40]。聚醚醚酮及其复合材料抗老化性和化学稳定性实验研究汇总,见表4。"

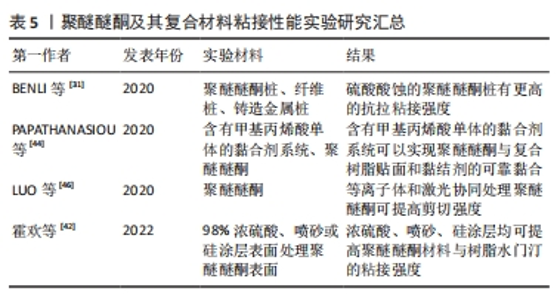

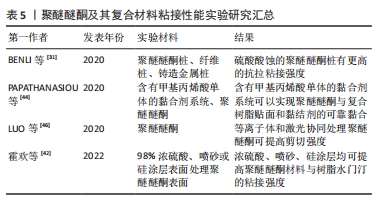

2.5 聚醚醚酮的粘接性能 理想的桩核材料要与根管壁之间实现良好的粘接[9]。聚醚醚酮为生物惰性材料,表面能较低且改性困难,聚醚醚酮桩与牙本质的良好粘接仍是临床应用中的挑战。可以通过3D打印技术、注塑成型技术或计算机辅助设计与计算机辅助制作技术(CAD/CAM)制作聚醚醚酮一体式桩核,使桩与根管形态良好匹配。BENLI等[31]比较聚醚醚酮桩、纤维桩、铸造金属桩的拉伸粘接强度和表面粗糙度,并且将桩核表面进行适当处理,实验结果显示经过硫酸酸蚀聚醚醚酮桩有更高的抗拉粘接强度,电镜下观察该材料表面有不规则的凹凸结构,增加了表面粗糙度。酸蚀聚醚醚酮操作简单,直接浸泡在浓硫酸溶液中即可得到满意的酸蚀面,但是酸蚀处理在椅旁操作存在安全隐患,并且处理时间过长后材料表面出现劣化现象,导致粘接强度降低[41]。因此学者提出了其他表面处理方法,如喷砂、激光、硅涂层、非等离子体处理等。霍欢等[42]发现98%浓硫酸、喷砂或硅涂层表面处理均可提高聚醚醚酮与树脂水门汀的粘接强度。对浓硫酸处理后的聚醚醚酮进行X射线光电子能谱仪分析,发现浓硫酸可以打开聚醚醚酮苯环之间的功能性羟基与醚基,暴露更多官能团,并且能够在材料表面引入氧,提高材料表面的湿润性和极性,使树脂更好地渗透[43]。浓硫酸可以实现聚醚醚酮分子中苯环的磺化反应,反应中生成的磺酸基团(-SO3H)还可与粘接剂中的甲基丙烯酸甲酯发生反应,提高粘接性能。大多数研究得出结论,当使用含有甲基丙烯酸单体的黏合剂系统(如Signum聚醚醚酮黏合剂和Visio)对聚醚醚酮表面进行预处理时,可实现与复合树脂贴面和黏结剂的可靠黏合[44]。利用飞秒激光处理和磁控溅射技术在聚醚醚酮表面制备一层亲水性的钽膜,可改善聚醚醚酮的表面形貌和湿润性,提高粘接强度[45]。LUO等[46]利用等离子体和激光协同处理碳纤维增强聚醚醚酮,材料的剪切强度由5.78 MPa提高到39.05 MPa,证明50 W连续光纤激光可在宏观上提高碳纤维的层间结合和结晶度,常压等离子体可在微观上改善聚醚醚酮与碳纤维的界面结合。 聚醚醚酮和浓硫酸的磺化反应受温度和时间的影响。当磺化温度为55 ℃时反应5 h,磺化度为95%,升高温度可加快反应速率[47],但是磺化后的聚醚醚酮会残留具有细胞毒性的含硫化合物,所以需再次水热处理降低残留物的含量[48]。当前缺乏有关聚醚醚酮桩长期粘接性能的研究数据,以及真实口腔环境和老化对聚醚醚酮粘接效果影响的相关研究。聚醚醚酮及其复合材料粘接性能实验研究汇总,见表5。"

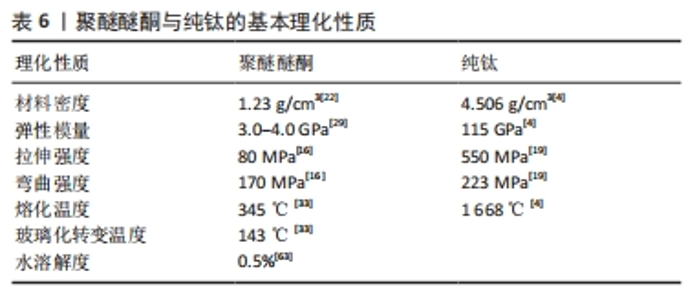

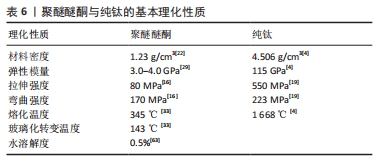

2.6 聚醚醚酮的生物相容性 口腔修复学中的桩核冠属于国家规定的第三类医疗器械,要求临床应用的桩核材料需具有良好的生物相容性,目前已有大量体外实验证明聚醚醚酮及其复合材料无生物毒性。许朗等[49]利用等离子体浸没离子注入技术将锆离子注入聚醚醚酮,实验证明经过改性后的聚醚醚酮表面促进了牙龈成纤维细胞的早期黏附增殖,细胞铺展更佳,细胞伪足更多,表现出良好的生物相容性。MAY[50]将聚醚醚酮试件植入兔子和大鼠体内,24-30 周后发现聚醚醚酮材料在动物体内的炎症反应极弱,没有发生异物反应。ZHAO等[51]通过使用细胞培养氨基酸稳定同位素标记分析了钛和聚醚醚酮培养的人成骨样MG-63细胞中蛋白质的动态表达变化,发现钛和聚醚醚酮的细胞表达变化模式相似,细胞适应性无明显差异,提示了聚醚醚酮具有优良的生物相容性。赵婷[21]的体外实验证明,不同质量分数(0%,30%,40%,50%)玻璃纤维增强型聚醚醚酮均有良好的细胞安全性,各材料试件的细胞增殖率均在70%以上,符合生物材料标准。 2.7 聚醚醚酮的其他性能 聚醚醚酮颜色偏灰,通透率低,不宜直接用作前牙区的美学修复,可以通过黏合树脂、饰面、调色等方法进行修饰[52]。陆伟等[53]利用聚合物共混改性和增材制造技术,采用3D打印技术制作出牙齿色和牙龈色一体化的聚醚醚酮复合物修复体,将配比合适的二氧化钛(TiO2)、氧化锆颗粒添加到聚醚醚酮材料中,得到了从白色向米黄色颜色转变的复合物,用于制作牙齿色修复体;再继续添加不同含量的氧化铁红或氧化铁黄,得到牙龈色复合物[54]。借鉴金属烤瓷修复体的制作方法,对聚醚醚酮修复体表面进行粗化联合饰面树脂烤塑可以改善聚醚醚酮的颜色[54]。 当聚醚醚酮及其复合材料用于桩核修复时,椅旁调改后需要精细抛光来降低表面粗糙度和细菌附着。目前临床和实验研究中常用Vita Enamic? Polishing Set抛光系统对聚醚醚酮材料进行抛光,系统的抛光成分主要是碳化硅和金刚石颗粒[55]。刘恒妍等[56]通过比较不同抛光材料对聚醚醚酮及复合材料的抛光效果,发现经橡胶磨头CERAMAGE Polishing Kit抛光系统(SHOFO,日本)抛光的纯聚醚醚酮、含纳米陶瓷和二氧化钛填料的聚醚醚酮表面划痕较少、光泽度更高、表面粗糙度接近树脂基陶瓷,推荐临床使用。 通过表面改性后的聚醚醚酮可具有抗菌性。聚醚醚酮与浓硫酸发生磺化反应,反应后聚醚醚酮表面的硫成分能抑制粪肠球菌形成菌斑生物膜,同时磺化后的聚醚醚酮材料表面形成有抗菌活性的网格状[57]。除了浓硫酸,聚醚醚酮还可以和气态三氧化硫(SO3)发生磺化反应,WAN等[58]发现在75 ℃时聚醚醚酮与气态SO3反应后聚醚醚酮表面磷灰石矿物沉积增加,可显著提高蛋白质的吸收。银离子是常见的金属抗菌剂,利用等离子喷涂技术,通过高温等离子焰流将含银离子的涂层材料加热至熔融并喷溅在聚醚醚酮材料表面,使聚醚醚酮材料表面形成均匀的含银离子涂层,提高聚醚醚酮材料的抗菌活性[59]。CHEN等[60]将聚醚醚酮试件置于多巴胺溶液中,再将试件置于不同浓度的AgNO3溶液中,银离子附着在聚醚醚酮表面,碱性磷酸酶活性检测发现改性后的聚醚醚酮试件可促进细胞生长。 聚醚醚酮具有透射性,在核磁成像(MRI)检查中伪影较少,在影像学检查中比金属铸造桩具有优势[61]。在关节外科中,FLEEGE等[62]通过对两组患者体内的纤维增强聚醚醚酮和纯钛椎弓螺钉进行核磁成像检测,发现纤维增强聚醚醚酮椎体在周围组织中无伪影区域为67.1%,纯钛椎体无伪影区域为48.3%,说明聚醚醚酮比纯钛在MRI检查中更具有优势。聚醚醚酮与纯钛的基本理化性质见表6。"

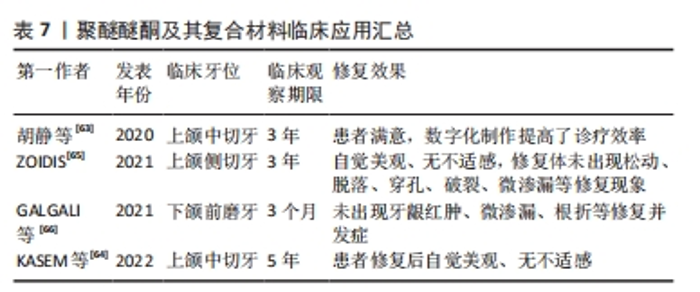

2.8 聚醚醚酮及其复合材料的临床应用 聚醚醚酮作为桩核材料的临床病例局限于前牙和前磨牙,并且都获得了满意的修复效果,见表7。胡静等[63]采用数字化技术制作聚醚醚酮桩核和二氧化锆全瓷冠对1例上前牙创伤患者进行修复治疗,获得了满意的治疗效果,数字化制作一次完成,减少了患者就诊次数,提高了诊疗效率。KASEM等[64]利用计算机辅助设计与计算机辅助制作技术制作聚醚醚酮桩,结合全瓷冠修复上颌中切牙,在5年的随访中患者对修复效果满意,显示聚醚醚酮桩核可以成为临床中选择的治疗方案。ZOIDIS[65]利用注塑成型技术制作聚醚醚酮桩,其与根管匹配性和精度良好,配合二硅酸锂陶瓷全冠修复上颌侧切牙,在3年的观察期内患者修复后自觉美观、无不适感,修复体未出现松动、脱落、穿孔、破裂、微渗漏等修复现象,表明在与二硅酸锂全冠结合时聚醚醚酮桩核可以代替金属铸造桩和纤维桩。2021年, GALGALI等[66]报道了1例计算机辅助设计与计算机辅助制作技术制作的聚醚醚酮桩核配合烤瓷冠修复左侧下颌前磨牙的病例,聚醚醚酮桩核用双固化树脂水门汀(Densply Sirona Calibra美学树脂水门汀)粘接,烤瓷冠用树脂改良玻璃离子水门汀粘接,对患者进行1周、1个月、3个月的随访,随访期间未出现牙龈红肿、微渗漏、根折等修复并发症,提示聚醚醚酮可以用作桩核修复材料。"

| [1] 刘林,甘抗,王艺婷,等.两种桩核系统修复剩余不同数目侧壁残冠的抗折性研究[J].口腔颌面修复学杂志,2018,19(2):65-69. [2] LI X, KANG T, ZHAN D, et al. Biomechanical behavior of endocrowns vs fiber post-core-crown vs cast post-core-crown for the restoration of maxillary central incisors with 1 mm and 2 mm ferrule height: A 3D static linear finite element analysis. Medicine (Baltimore). 2020;99(43):e22648. [3] 李征,王媛,田梦婷,等.桩核表面制备不同形式固位槽及使用不同黏结剂对固位力的影响[J].中国组织工程研究,2020,24(34):5508-5513. [4] BADAMI V, KETINENI H, PB S, et al.Comparative Evaluation of Different Post Materials on Stress Distribution in Endodontically Treated Teeth Using the Finite Element Analysis Method: A Systematic Review. Cureus. 2022;14(9):e29753. [5] STRICKER EJ, GÖHRING TN. Influence of different posts and cores on marginal adaptation, fracture resistance, and fracture mode of composite resin crowns on human mandibular premolars. An in vitro study. J Dent. 2006;34(5):326-335. [6] UPADHYAYA V,BHARGAVA A,PARKASH H, et al. A finite element study of teeth restored with post and core: Effect of design, material, and ferrule. Dent Res J (Isfahan). 2016;13(3):233-238. [7] NAM SH, CHANG HS, MIN KS, et al. Effect of the number of resid-ual walls on fracture resistances, failure patterns, and photoelas-ticity of simulated premolars restored with or without fiber-rein-forced composite posts. J Endod. 2010;36(2):297-301. [8] 孙晟杰.下颌第一前磨牙大面积缺损纤维桩冠修复的三维有限元分析[D].南昌:南昌大学,2023. [9] 杨艺强,刘琪,于慧宁,等.3D打印个体化桩核修复漏斗状根管的适合性研究[J].宁夏医学杂志,2023,45(3):233-235. [10] FERRARI M, VICHI A, MANNOCCI F, et al. Retrospective study of the clinical performance of fiber posts. Am J Dent. 2000;13(Spec No):9B-13B. [11] CALABRO DE, KOJIMA AN, GALLEGO ARIAS PECORARI V, et al. A 10-year follow-up of different intraradicular retainers in teeth restored with Zirconia Crowns. Clin Cosmet Investig Dent. 2019;11:409-417. [12] MARTINS MD, JUNQUEIRA RB, DE CARVALHO RF, et al. Is a fiber post better than a metal post for the restoration of endodontically treated teeth? A systematic review and meta-analysis. J Dent. 2021;112:103750. [13] 陈志宇,郭晓阳,付艺璇,等.不同个性化桩核材料修复重度缺损上前牙的三维有限元分析[J].实用口腔医学杂志,2021,37(5):671-675. [14] PENTEADO MM, DE ANDRADE GS, ARAUJO RM, et al. Fatigue survival of endodontically treated teeth restored with different fiber-reinforced composite resin post strategies versus universal 2-piece fiber post system: An in vitro study. J Prosthet Dent. 2023;129(3):456-463. [15] 王效平,高卫民,陈溯,等.不同直径预成氧化锆桩和纤维桩修复的抗折性比较[J].北京口腔医学,2013,21(2):89-91. [16] SCHWITALLA AD, SPINTIG T, KALLAGE I, et al. Flexural behavior of PEEK materials for dental application. Dent Mater. 2015;31(11):1377-1384. [17] 鲁晨,陶璐,项闫颜,等.聚醚醚酮改性及在口腔种植领域的应用研究[J].实用口腔医学杂志,2020,36(5):819-824. [18] QIN L, YAO S, ZHAO J, et al. Review on development and dental applications of polyetheretherketone-based biomaterials and restorations. Materials (Basel). 2021;14(2):408. [19] 周哲.不同碳纤维增强聚醚醚酮种植体的制备及力学性能研究[D].长春:吉林大学,2023. [20] 米莲,柏娜.3D打印聚醚醚酮及复合材料在口腔医学领域的研究进展[J].暨南大学学报,2022,43(6):616-622,642. [21] 赵婷.玻璃纤维增强聚醚醚酮桩核材料的初步研究[D].长春:吉林大学,2023. [22] 张伟芳,刘吕花,刘英,等.聚醚醚酮在口腔医学中应用的研究进展[J].工程塑料应用,2022,50(11):163-167. [23] ALABBADI AA, ABDALLA EM, HANAFY SA, et al. A comparative study of CAD/CAM fabricated polyether ether ketone and fiber-glass reinforcement composites versus metal lingual retainers under vertical load (an in vitro study). BMC Oral Health. 2023;23(1):583. [24] PENG TY, SHIH YH, HSIA SM, et al. In Vitro Assessment of the Cell Metabolic Activity, Cytotoxicity, Cell Attachment, and Inflammatory Reaction of Human Oral Fibroblasts on Polyetheretherketone (PEEK) Implant-Abutment. Polymers (Basel). 2021;13(17):2995. [25] TEIXEIRA KN, DUQUE TM, MAIA HP, et al. Fracture Resistance and Failure Mode of Custom-made Postand-cores of Polyetheretherketone and Nano-ceramic Composite. Oper Dent. 2020;45(5):506-515. [26] ÖZARSLAN M, BÜYÜKKAPLAN UŞ, ÖZARSLAN MM. Comparison of the fracture strength of endodontically treated teeth restored with polyether ether ketone, zirconia and glass-fibre post-core systems. Int J Clin Pract. 2021;75(9):e14440. [27] 于豪,白石柱,冯志宏,等.聚醚醚酮用于桩核冠修复的三维有限元分析[J].实用口腔医学杂志,2020,36(1):5-9. [28] 曾亚楠.聚醚醚酮桩核修复后抗折性能及失效模式分析[D].南昌:南昌大学,2023. [29] 刘国江,杨丽,冯剑桥.聚醚醚酮桩核在上颌中切牙修复时的三维有限元分析[J].哈尔滨医科大学学报,2022,56(6):580-583. [30] NAHAR R, MISHRA SK, CHOWDHARY R. Evaluation of stress distribution in an endodontically treated tooth restored with four different post systems and two different crowns- A finite element analysis. J Oral Biol Craniofac Res. 2020;10(4):719-726. [31] BENLI M, EKER GÜMÜŞ B, KAHRAMAN Y, et al. Surface characterization and bonding properties of milled polyetheretherketone dental posts. Odontology. 2020;108(4):596-606. [32] 庞馨蕾,白瑜,王洪学.聚合反应时间对聚醚醚酮性能的影响[J/OL].石油化工:1-9[2023-07-27]. https://kns.cnki.net/kcms2/article/abstract? [33] SUGANO K, KOMADA W, OKADA D, et al. Evaluation of composite resin core with prefabricated polyetheretherketone post on fracture resistance in the case of flared root canals. Dent Mater J. 2020;39(6):924-932. [34] NIEM T, YOUSSEF N, WÖSTMANN B. Influence of accelerated ageing on the physical properties of CAD/CAM restorative materials. Clin Oral Investig. 2020;24(7):2415-2425. [35] LIEBERMANN A, WIMMER T, SCHMIDLIN PR, et al. Physicomechanical characterization of polyetheretherketone and current esthetic dental CAD/CAM polymers after aging in different storage media. J Prosthet Dent. 2016;115(3): 321-8.e2. [36] 常旭阳.聚醚醚酮物理老化行为研究[D].大连:大连理工大学,2019. [37] BOONPOK S, KOONRUNGSRISOMBOON K, SUTTIAT K, et al. Dissolution Behavior of Hydrothermally Treated Hydroxyapatite-Titanium Nitride Films Coated on PEEK: In Vitro Study. J Funct Biomater. 2022;13(3):99. [38] BOINARD E, PETHRICK RA, MACFARLANE CJ. The influence of thermal history on the dynamic mechanical and dielectric studies of polyetheretherketone exposed to water and brine. Polymer. 2000;41(3):1063-1076. [39] 孙岩,王登霞,李家恺,等.高性能聚醚醚酮紫外光加速老化行为研究[J].装备环境工程,2023,20(8):98-104. [40] 张腾月,肖川,陈鹏万,等.聚醚醚酮壳体战斗部爆破威力试验[J].爆炸与冲击,2023,43(9):220-228. [41] SPROESSER O, SCHMIDLIN PR, UHRENBACHER J, et al. Effect of sulfu-ric acid etching of polyetheretherketone on the shear bond strength to resin cements. J Adhes Dent. 2014;16(5):465-472. [42] 霍欢,张海兵,周慧,等.不同表面处理方法对聚醚醚酮冠桥材料粘接性能的影响[J].临床口腔医学杂志,2022,38(9):519-523. [43] SAVYCHUK A, MANDA M, GALANIS C, et al. Stress generation in mandibular anterior teeth restored with different types of post-and-core at various levels of ferrule. J Prosthet Dent. 2018;119(6):965-974. [44] PAPATHANASIOU I, KAMPOSIORA P, PAPAVASILIOU G, et al. The use of PEEK in digital prosthodontics: A narrative review. BMC Oral Health. 2020; 20(1):217. [45] 焦艳,李晓红,赖舟语,等.改善聚醚醚酮表面润湿性的研究[J].科技创新与生产力,2022(11):88-91. [46] LUO M, TIAN X, SHANG J, et al. Bi-scale interfacial bond behaviors of CCF/PEEK composites by plasma-laser cooperatively assisted 3D printing process. COMPOS Part A-APPL S. 2020;131:105812. [47] 陈俊俊,费昌恩,段金汤,等.高生物活性聚醚醚酮化学改性研究进展[J].化工进展,2023,42(8):4015-4028. [48] OUYANG L, ZHAO Y, JIN G, et al. Influence of sulfur content on bone formation and antibacterial ability of sulfonated PEEK. Biomaterials. 2016; 83:115-126. [49] 许朗,黄忠卫,石锐.锆等离子体浸没离子注入增强聚醚醚酮材料的细胞相容性[J].局解手术学杂志,2023,32(9):760-763. [50] MAY R. Polyetheretherketones// MARK HF, BIKALES NM, OVERBERGER CG, et al. Encyclopedia of polymer science and engineering. New York: Wiley, 1988:313-320. [51] ZHAO M, AN M, WANG Q, et al. Quantitative proteomic analysis of human osteoblast-like MG-63 cells in response to bioinert implant material titanium and polyetheretherketone. J Proteomics. 2012;75(12):3560-3573. [52] 刘更,史作慧,黄锦梅,等.聚醚醚酮口腔生物材料性能优化的研究进展[J].医药论坛杂志,2022,43(22):110-113. [53] 陆伟,陈曦.一体化双色3D打印聚醚醚酮口腔修复体的初步临床报告[J].实用口腔医学杂志,2020,36(3)548-552. [54] STAWARCZYK B, SCHMID P, ROOS M, et al. Spectrophotometric evaluation of Polyetheretherketone (PEEK) as a Core material and a comparison with gold standard Core materials. Materials (Basel). 2016;9(6):491. [55] 王睿瑾,张嘉琪,衣颖杰,等.牙科可切削聚醚醚酮表面抛光性能的初步研究[J].中华口腔医学研究杂志(电子版),2021,15(5):278-283. [56] 刘恒妍,刘昱晨,李康杰,等.不同椅旁抛光系统对聚醚醚酮抛光效果的比较[J].口腔疾病防治,2023,31(12):884-854. [57] HAN X, GAO W, ZHOU Z, et al. Application of biomolecules modification strategies on PEEK and its composites for osteogenesis and antibacterial properties. Colloids Surf B Biointerfaces. 2022;215:112492. [58] WAN T, JIAO Z, GUO M, et al. Gaseous sulfur trioxide induced controllable sulfonation promoting biomineralization and osseointegration of polyetheretherketone implants. Bioact Mater. 2020;5(4):1004-1017. [59] QING Y, CHENG L, LI R, et al. Potential antibacterial mechanism of silver nanoparticles and the optimization of orthopedic implants by advanced modification technologies. Int J Nanomedicine. 2018;13:3311-3327. [60] CHEN W, ZHANG X, TAN D, et al. Improvement in Mechanical Properties of 3D-Printed PEEK Structure by Nonsolvent Vapor Annealing. Macromol Rapid Commun. 2022;43(7):e2100874. [61] RAHMITASARI F, ISHIDA Y, KURAHASHI K, et al. PEEK with Reinforced Materials and Modifications for Dental Implant Applications. Dent J (Basel). 2017;5(4):35. [62] FLEEGE C, MAKOWSKI M, RAUSCHMANN M, et al. Carbon fiber-reinforced pedicle screws reduce artifacts in magnetic resonance imaging of patients with lumbar spondylodesis. Sci Rep. 2020;10(1):16094. [63] 胡静,钟声,越野,等.数字化制作PEEK桩核+全瓷冠修复一例[C].第十次全国口腔修复工艺学学术年会,2020. [64] KASEM AT, SHAMS M, TRIBST JPM. The Use of Polyetheretherketone (PEEK) as an Alternative Post and Core Material: Five-Year Follow-Up Report. Dent J (Basel). 2022;10(12):237. [65] ZOIDIS P. The use of modified polyetheretherketone post and core for an esthetic lithium disilicate anterior ceramic restoration: a clinical report. Int J Prosthodont. 2021;34(1):120-125. [66] GALGALI NR, DANGE SP, MAHALE KM, et al. A novel approach of restoring endodontically treated tooth by using cad-cam milled peek post and core system: a case report. Int J Applied Dent Sci. 2021;7(4):9-13. [67] 谭颖,饶思晗,孙纪奎,等.聚醚醚酮在桩核修复中的应用进展[J].口腔颌面修复学杂志,2022,23(6):450-455,466. [68] 许晓杰,赵媛.聚醚醚酮在桩核冠修复中的应用前景[J].口腔疾病防治, 2022,30(12):902-906. [69] NAJEEB S, ZAFAR MS, KHURSHID Z, et al. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J Prosthodont Res. 2016;60(1):12-19. [70] 曲涵.生物活性玻璃改性聚醚醚酮增材制造及其生物特性研究[D].长春:吉林大学,2023. [71] LIBONATI A, DI TV, GALLUSI G, et al. CAD/CAM customized glass fiber post and core with digital intraoral impression: a case report. Clin Cosmet Investig Dent. 2020;12:17-24. |

| [1] | Yu Weijie, Liu Aifeng, Chen Jixin, Guo Tianci, Jia Yizhen, Feng Huichuan, Yang Jialin. Advantages and application strategies of machine learning in diagnosis and treatment of lumbar disc herniation [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(9): 1426-1435. |

| [2] | Lin Zeyu, Xu Lin. Research progress in gout-induced bone destruction mechanism [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(8): 1295-1300. |

| [3] | Ma Shuwei, He Sheng, Han Bing, Zhang Liaoyun. Exosomes derived from mesenchymal stem cells in treatment of animals with acute liver failure: a meta-analysis [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(7): 1137-1142. |

| [4] | Zhang Kefan, Shi Hui. Research status and application prospect of cytokine therapy for osteoarthritis [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(6): 961-967. |

| [5] | Li Jiaqi, Huang Yuanli, Li Yan, Wang Chunren, Han Qianqian. Mechanism and influencing factors in molecular weight degradation of non-cross-linked hyaluronic acid [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(5): 747-752. |

| [6] | Xu Rong, Wang Haojie, Geng Mengxiang, Meng Kai, Wang Hui, Zhang Keqin, Zhao Huijing. Research advance in preparation and functional modification of porous polytetrafluoroethylene artificial blood vessels [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(5): 759-765. |

| [7] | Chen Xiaofang, Zheng Guoshuang, Li Maoyuan, Yu Weiting. Preparation and application of injectable sodium alginate hydrogels [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(5): 789-794. |

| [8] | Liu Chuang, Shan Shuo, Yu Tengbo, Zhou Huan, Yang Lei. Advantages, discomfort and challenges of clinical application of orthopedic hemostatic materials [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(5): 795-803. |

| [9] | Zhang Ming, Wang Bin, Jia Fan, Chen Jie, Tang Wei. Application of brain-computer interface technology based on electroencephalogram in upper limb motor function rehabilitation of stroke patients [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(4): 581-586. |

| [10] | He Yuanjie, Chen Yuheng, Zhao Yongchao, Wang Zhenglong. Progress in epigenetic regulation of vascular smooth muscle cell remodeling in the occurrence and development of aortic aneurysms [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(4): 602-608. |

| [11] | Ma Sicong, Chen Jing, Li Yunqing. Functions and roles of connective tissue growth factor in nervous systems [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(4): 615-620. |

| [12] | Yan Binghan, Li Zhichao, Su Hui, Xue Haipeng, Xu Zhanwang, Tan Guoqing. Mechanisms of traditional Chinese medicine monomers in the treatment of osteoarthritis by targeting autophagy [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(4): 627-632. |

| [13] | Zhi Liang, Wang Yulong, Zhang Qingfang, Hong Yaqing, Ke Meihua, Liu Quanquan, Long Jianjun. Propulsion deficits in hemiplegic gait of stroke patients [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(35): 5709-5715. |

| [14] | Wang Wenchi, Wu Ruiqi, Huang Jierong, Zhu Lifeng, Cui Xianqin, Li Dongzong, Chen Wenhui, Lin Chunting, Cui wei. Molecular mechanism of naringin in prevention and treatment of osteoporosis [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(34): 5528-5535. |

| [15] | Li Qi, Gao Mingwei, Li Shihao, Chu Xiaolei, Li Yajie, Ding Ning, Liu Minqi. Rate of force development and its relationship with functional performance in patients after anterior cruciate ligament reconstruction [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(34): 5536-5543. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||